Golf bag production has a hidden environmental cost tied to materials, energy use, and waste. Most bags rely on petroleum-based fabrics like polyester and nylon, which require energy-intensive processes. Factories often depend on fossil fuels, contributing to emissions, while transportation and packaging add further impact. Waste, from fabric scraps to non-biodegradable materials, exacerbates the problem.

Switching to eco-friendly materials and cleaner production methods can cut emissions significantly. Options like recycled polyester (rPET), hemp, and algae-based foams replace petroleum-based components while maintaining durability. Renewable energy, waste recycling, and local sourcing further reduce the carbon footprint.

Key takeaways:

- Materials: Recycled fabrics (e.g., rPET) and plant-based options (hemp, algae foam) lower emissions.

- Energy: Factories powered by solar or wind energy reduce reliance on fossil fuels.

- Waste: Circular systems recycle byproducts, cutting landfill impact.

- Metrics: Tracking emissions and energy usage helps measure progress.

These changes align with consumer demand for greener products while reducing costs over time. Golf bag manufacturers can adopt these practices to produce high-quality, eco-conscious products.

Wilson Eco Golf Stand Bag – Made From Plastic Bottles – Review

Eco-Friendly Materials for Golf Bag Production

Switching to sustainable materials in golf bag manufacturing can cut emissions while maintaining durability and protection. These innovations replace petroleum-based fabrics and foams with recycled or plant-based alternatives that perform just as well in everyday use.

Using Recycled Fabrics and Plastics

Recycled polyester (rPET) is made by transforming single-use plastic bottles into high-performance fabric. To produce the yarn for just one golf bag, about 27 plastic bottles are repurposed. Jones Golf Bags, for example, introduced their R-series, which uses this material:

"The new R-series features a recycled, ripstop fabric made entirely from PET bottles. A highly durable, water-resistant fabric."

This recycled polyester isn’t just eco-friendly – it uses 50% less energy and emits 70% less CO₂ compared to virgin polyester.

Another option is recycled nylon, sourced from discarded fishing nets. Companies like Seawastex collect ocean plastics and convert them into durable, moisture-resistant ripstop fabric. By doing so, they help reduce waste in both landfills and oceans. Certifications such as bluesign® and Oeko-Tex® Standard 100 ensure these materials meet strict safety and sustainability standards. Impressively, 83% of garments in some modern golf collections now incorporate certified recycled fabrics.

But recycled fibers aren’t the only solution – plant-based materials also offer exciting possibilities.

Plant-Based Materials: Hemp and Algae Foam

Hemp is a natural alternative to synthetic fabrics. According to Haglöfs:

"Hemp is the strongest cellulosic natural fiber and resists degradation from sun and water."

This makes hemp an excellent choice for golf bags that need to withstand UV exposure and rain. Plus, it’s biodegradable, eliminating the need for petroleum-based production.

For padding and support, algae-based foams like BLOOM™ provide a sustainable replacement for traditional petroleum-based foams. These foams are created from harvested algae, reducing reliance on fossil fuels. Additionally, bio-polymers derived from food production waste – such as walnut shells and olive pits – are used for zippers and hardware. This switch reduces carbon emissions by 41%, eliminates 500 kg of plastic waste per ton, and produces biodegradable microplastics that break down at about 10% per month in industrial composting.

| Material Type | Sustainable Option | Key Environmental Benefit |

|---|---|---|

| Fabric | Recycled Polyester (rPET) | 70% lower CO₂ emissions |

| Fabric | Hemp | Strongest natural fiber; UV resistant |

| Foam/Padding | BLOOM™ Algae Foam | Cleans waterways; reduces oil reliance |

| Structural Parts | Bio-polymers (Food waste) | 41% lower carbon footprint |

Greener Production Methods

Using sustainable materials is just the first step – how products are made plays a huge role in determining their overall carbon footprint. Factories reliant on fossil fuels and those generating excessive waste significantly increase emissions. By switching to renewable energy and adopting circular systems that recycle byproducts, manufacturers can make a big dent in their carbon output. Let’s dive into how renewable energy is reshaping production.

Powering Factories with Renewable Energy

Replacing coal and natural gas with solar and wind power in manufacturing facilities can drastically cut emissions tied to electricity use. For instance, Acushnet Company entered Power Purchase Agreements between 2012 and 2014 to fund four large-scale solar farms in Massachusetts. These farms generate 17,000 MWh annually, and Acushnet buys 100% of the energy credits they produce. In 2022, the company went further by installing a rooftop solar array at its golf ball plant in Thailand.

Yonex GmbH has also embraced solar energy, outfitting its German facility with rooftop solar panels. This setup now meets over 50% of the facility’s yearly electricity needs, helping the company achieve a 25% reduction in Scope 1 and 2 CO₂ emissions by 2024 compared to 2016 levels. In regions with strong winds, on-site turbines can also provide power for operations and maintenance.

Some manufacturers are turning to Combined Heat and Power (CHP) systems, which capture and use heat that would otherwise be wasted during electricity generation. Acushnet has implemented CHP systems at two of its Massachusetts plants, resulting in greater efficiency and lower emissions than traditional power methods. Nike, on the other hand, reported that 96% of the electricity used across its global operations in FY24 came from renewable sources, leading to a 69% absolute reduction in Scope 1 and 2 greenhouse gas emissions compared to FY20.

While renewable energy is key to lowering emissions, reducing production waste is another critical piece of the puzzle.

Reducing Waste in Manufacturing

Circular production systems focus on recycling byproducts instead of sending them to landfills. Many advanced manufacturing setups now achieve waste diversion rates of 95% to 100%, with over 60% of waste being reused or recycled . For example, Acushnet has implemented closed-loop water recycling technology at its golf ball subsidiary, cutting water usage by 5,000 gallons daily. The company also achieved an impressive 85% waste diversion rate in its club operations.

Precision technologies like AI-driven material selection and 3D printing are helping manufacturers reduce the amount of raw material wasted during production. Additionally, modular design – where products are made with easily repairable or replaceable components – extends their lifespan and minimizes waste at the end of their life cycle. These strategies not only conserve resources but also contribute to a more sustainable production process.

sbb-itb-4fa7e8b

Keep Perfect Golf‘s Approach to Eco-Friendly Manufacturing

At Keep Perfect Golf, sustainability isn’t just a buzzword – it’s a principle woven into every step of creating custom golf bags. From the materials we use to the way we produce and deliver our products, we aim to reduce environmental impact while maintaining exceptional quality.

Eco-Friendly Materials for Custom Bags

The foundation of our eco-conscious approach lies in the materials we use. Clients can select from options like GRS-certified recycled ripstop, Repreve performance fibers, or Seawastex® nylon, which is crafted from reclaimed ocean fishing nets.

We also focus on durability to extend the life of our products. For instance, our custom bags can feature 100% magnetic closures instead of zippers, which are often the first part to fail, leading to unnecessary waste. Some designs even include integrated solar chargers, offering golfers a renewable energy source while out on the course.

Streamlined Production and Shipping

To cut down on carbon emissions, we source most of our materials within a 62-mile radius of our headquarters. This local sourcing strategy reduces the environmental impact of transportation while supporting nearby suppliers.

Additionally, our factory-to-consumer model eliminates extra shipping steps, ensuring a more efficient delivery process. By engineering our golf bags for a lifespan of 5–8 years, we help reduce the frequency of replacements, which in turn lowers manufacturing demand. These efforts allow clients to meet their environmental goals without sacrificing quality or performance.

Tracking and Improving Carbon Reduction Efforts

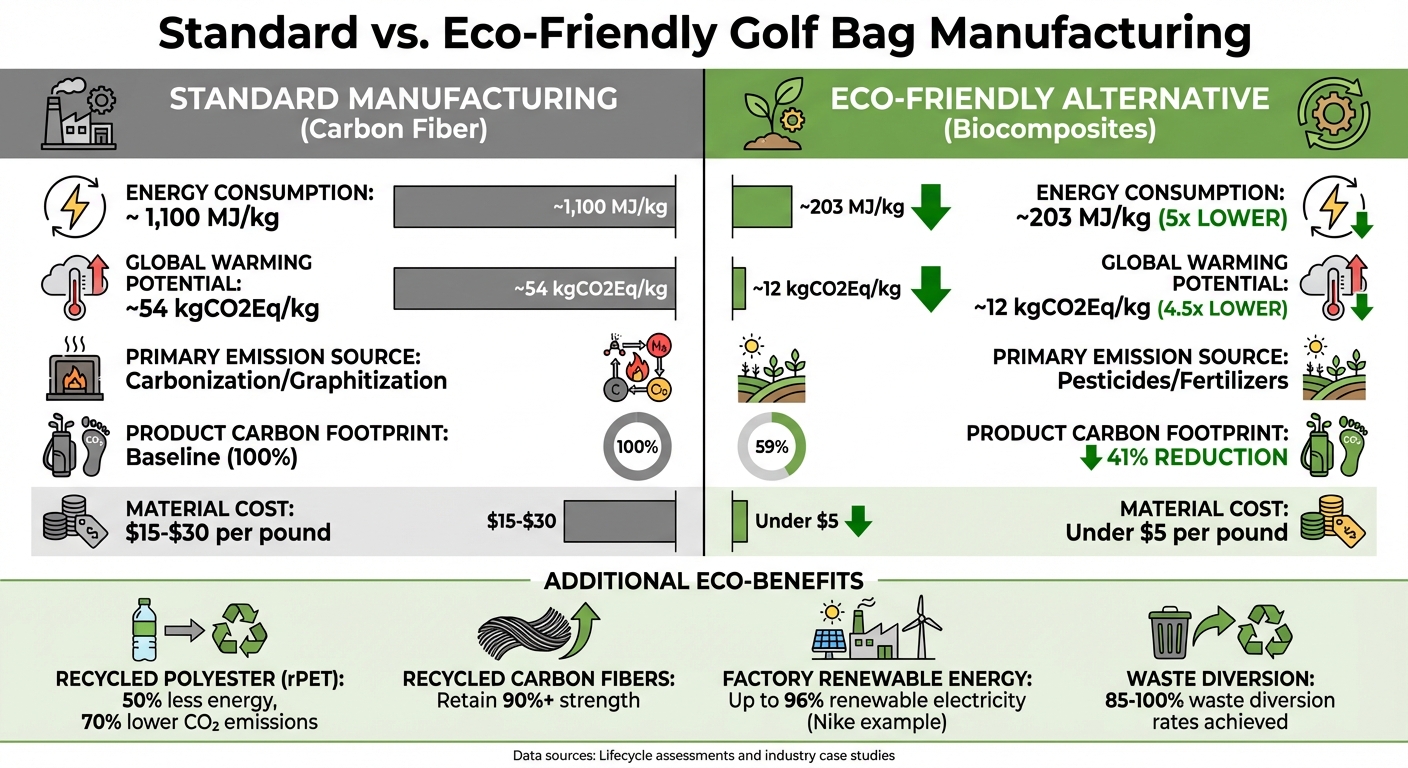

Standard vs Eco-Friendly Golf Bag Manufacturing: Energy and Emissions Comparison

Key Metrics for Measuring Sustainability

To gauge sustainability efforts effectively, it’s crucial to track a few key metrics. One important measure is the Global Warming Potential (GWP), expressed in kgCO2Eq/kg. This figure captures total emissions across the lifecycle – from raw material extraction to production. Another critical metric is energy use, measured in MJ/kg, which helps identify energy-intensive processes like carbonization and autoclave curing.

Broadening the scope, monitoring supplier greenhouse gas inventories – especially for suppliers accounting for 75–80% of spending – can provide deeper insights into emissions beyond the factory floor. Additionally, tracking material composition, such as the percentage of recycled content or the inclusion of bio-fillers like walnut shells in polymers, offers a clear picture of progress in reducing the Product Carbon Footprint (PCF). These metrics establish a foundation for ongoing improvement.

Standardized tools like the EPA’s WARM model and ENERGY STAR benchmarks are invaluable for tracking emissions and setting measurable baselines for improvement.

Standard vs. Eco-Friendly Manufacturing: A Comparison

These metrics underscore the advantages of adopting sustainable materials. For example, manufacturing carbon fiber composites requires roughly 1,100 MJ/kg of energy, whereas flax-based biocomposites need only about 203 MJ/kg – an energy demand that’s over five times lower. Similarly, carbon fiber production generates approximately 54 kgCO2Eq per kilogram, compared to just 12 kgCO2Eq for biocomposites. By incorporating biobased polymers, a product’s carbon footprint can be reduced by about 41% compared to conventional materials.

| Metric | Standard Manufacturing (Carbon Fiber) | Eco-Friendly Alternative (Biocomposites) |

|---|---|---|

| Energy Consumption | ~1,100 MJ/kg | ~203 MJ/kg |

| Global Warming Potential | ~54 kgCO2Eq/kg | ~12 kgCO2Eq/kg |

| Primary Emission Source | Carbonization/Graphitization | Pesticides/Fertilizers |

| Product Carbon Footprint Reduction | Baseline (100%) | ~41% Reduction |

The data speaks for itself: transitioning from traditional synthetic materials to plant-based alternatives significantly reduces energy consumption and slashes greenhouse gas emissions during production. These measurable benefits highlight the real-world impact of embracing greener materials and manufacturing practices.

Conclusion: Moving Toward Greener Golf Bag Manufacturing

Shifting to more sustainable practices in golf bag manufacturing isn’t just possible – it’s practical. For instance, using recycled polyester instead of virgin synthetics can slash energy consumption by 50% and cut carbon emissions by 70%. Similarly, recycled carbon fibers, which retain over 90% of their strength, are not only eco-friendly but also cost-effective, priced at under $5 per pound compared to $15–$30 for virgin materials. These changes don’t just benefit the environment – they make financial sense too.

Improving supply chains offers another quick win. By strategically positioning distribution centers near major ports and reducing excess packaging, manufacturers have managed to cut shipment volumes by 30%. Recycling programs further reduce dependency on virgin fossil fuels, showing that small adjustments can lead to big environmental gains.

These steps naturally align with circular economy principles, which emphasize durability and resource efficiency. Offering repair services, for example, extends the lifespan of golf bags, reducing the need for replacements and lowering overall emissions. Precision manufacturing, informed by historical data, minimizes material waste, while upcycling leftover fabrics into exclusive, limited-edition collections transforms waste into profit.

To take the next step, manufacturers can act now by auditing their suppliers, prioritizing single-fiber fabrics for easier recycling, and incorporating renewable energy into their production processes. The data is clear: sustainability and performance go hand in hand, meeting consumer expectations while addressing environmental challenges.

FAQs

What are the advantages of using recycled polyester in making golf bags?

Using recycled polyester to make golf bags comes with some impressive environmental perks. For starters, it cuts energy use by around 50% and slashes carbon emissions by nearly 70% compared to using new polyester. The best part? This material doesn’t compromise on durability or performance. Golf bags made with recycled polyester still deliver the quality players expect, all while supporting sustainability efforts.

How does switching to renewable energy in manufacturing help reduce carbon emissions?

Using energy sources like solar and wind power in manufacturing can dramatically lower carbon emissions by reducing reliance on fossil fuels. Unlike conventional energy options, these renewables generate zero direct CO₂ emissions during use, minimizing the environmental toll of production.

Switching to renewable energy allows manufacturers to shrink their carbon footprint while keeping production efficient. Plus, it’s a step toward creating a cleaner and more sustainable future.

How do plant-based materials like hemp and algae foam make golf bags more eco-friendly?

Plant-based materials, like hemp, are reshaping the way golf bags are made by swapping out petroleum-based plastics for renewable alternatives. Hemp can be turned into bio-plastics that match the strength and durability of traditional materials but with a much smaller carbon footprint. Plus, its impressive strength-to-weight ratio makes it perfect for crafting lightweight, sturdy golf bags that are not only easier to carry but also kinder to the planet.

Another promising material on the horizon is algae-derived foam. While still in its early stages, it has the potential to become a go-to eco-friendly option. Together, these advancements are working to reduce the environmental impact of manufacturing without compromising the quality or performance that golfers rely on.