Golf bags are evolving as manufacturers address concerns about waste, pollution, and material sourcing. Traditional bags, made from petroleum-based materials like polyester and nylon, often last 5–8 years before ending up in landfills. However, a shift toward recycled and biodegradable materials is reshaping the industry. Here’s how:

- Recycled Fabrics: Materials like Repreve® (made from plastic bottles) and Seawastex (recycled fishing nets) deliver durability, weather resistance, and reduced carbon emissions.

- Biodegradable Components: Natural fibers such as Harris Tweed, bamboo, and organic fleece replace petroleum-based hardware and liners.

- Recycled Ripstop: Lightweight and tear-resistant, this material is ideal for bags that endure frequent handling.

Golf brands are also adopting carbon-neutral manufacturing and ethical supply chains, sourcing up to 80% of materials locally to cut emissions. Programs like "Trade It Forward" extend bag lifespans, while innovations like magnetic closures reduce common durability issues.

Whether it’s Sun Mountain’s $250 Eco-Lite bags or Keep Perfect Golf’s customizable designs, eco-conscious options now offer the same performance as conventional bags, with less environmental impact. Golfers can now enjoy high-quality gear while supporting a cleaner planet.

Sun Mountain Ecolite GOLF Carry Bag Review

sbb-itb-4fa7e8b

Eco-Friendly Materials Used in Golf Bag Production

The move toward more sustainable golf bags involves three key material types: recycled plastic fabrics, biodegradable components, and recycled ripstop materials. Each material brings its own strengths in durability, weather resistance, and reduced environmental footprint – all without sacrificing performance on the course.

Recycled Plastic Fabrics and Their Benefits

Recycled PET fabrics, like Repreve®, have become a standout choice for eco-conscious golf bag production. These fabrics are crafted from recycled plastic water bottles and deliver the same UV protection, moisture management, and water resistance as virgin polyester. Even better, they reduce carbon emissions by 70% compared to traditional materials.

A prime example is Sun Mountain’s Eco-Lite series. Their stand bag, priced at $250, weighs just 4 pounds and is made entirely from Repreve® polyester yarn. This material not only resists fading from prolonged sun exposure but also offers excellent durability and weather protection – qualities that make it a great option for golfers who walk the course regularly. Traditional nylon bags often fade over time, but recycled polyester maintains its vibrant colors, meeting both practical and aesthetic needs.

In addition to recycled fabrics, manufacturers are incorporating biodegradable materials to enhance sustainability.

Biodegradable Materials for Hardware and Liners

Sustainability efforts now extend beyond fabrics to include biodegradable options for straps, liners, and hardware. Natural fibers and plant-based materials are replacing petroleum-based components. For instance, Harris Tweed, made from 100% British wool, serves as a biodegradable alternative for outer fabrics and headcovers, while also offering natural water resistance. Inside the bag, organic fleece is being used for linings, and Lyocell wadding, derived from sustainable wood pulp, provides structural padding.

Bamboo is another standout material, often used for tees and accents on golf bags. It’s durable, lightweight, and fully decomposes if left behind on the course. Other innovations include waxed organic cotton for headcovers and hemp straps, which deliver both weatherproofing and durability with minimal environmental impact.

To round out these advancements, recycled ripstop materials are setting new standards for sustainable durability.

Recycled Ripstop Materials

Recycled ripstop fabrics represent a significant leap in sustainable golf bag design. Jones Sports Co.’s R-series showcases this innovation with materials woven entirely from 100% PET single-use plastic bottles. Their Trouper 3.0 model, priced at $310, features this material and has been rigorously tested in the challenging weather conditions of the Pacific Northwest.

"The new R-series features a recycled, ripstop material, woven from 100% PET single-use plastic bottles. The most innovative, durable, and water-resistant fabric to date." – Jones Sports Co.

The unique reinforced weave of ripstop fabric makes it highly resistant to tears and abrasions, which is crucial for bags that face constant wear from cart straps, handling, and rough course conditions. Unlike canvas, which absorbs water and becomes heavy, recycled ripstop remains lightweight (typically 2-4 pounds) while offering excellent rain protection. It also holds dyes exceptionally well, making it perfect for vibrant colors and custom logos that stay vivid over time.

Advances in Sustainable Manufacturing

Modern manufacturing is evolving to align with eco-conscious goals. Companies are reevaluating every stage of production – from energy consumption to supply chain logistics – to reduce their carbon footprint, all while maintaining the quality and performance consumers expect.

Carbon-Neutral Manufacturing Methods

Achieving carbon neutrality involves a mix of efficient energy use, innovative materials, and strategic carbon offsetting. A notable example comes from November 2023, when Vessel partnered with Dow to produce luxury golf bags for the Solheim Cup using LuxSense™ Silicone Synthetic Leather. This material is designed to be 100% carbon neutral and avoids the energy-intensive tanning processes of traditional leather. It’s free from plasticizers, DMF, and volatile organic compounds (VOCs), with its carbon neutrality independently certified under the PAS 2060 standard.

"But the biggest challenge was infusing the bag with unparalleled levels of sustainability. To hit both needs, our new LuxSense™ solution was the clear choice." – Carlos Padilla II, Head of Global Sports Partnerships, Dow

Other companies are also making strides. In 2023, Big Max installed 430,000 square feet of solar panels on its factory roofs in Vietnam. These panels not only power machinery but also lower internal temperatures by 5 to 9°F, reducing the need for air conditioning. Additionally, the company replaced solvent-based finishes with a non-toxic powder coating system for its cart equipment.

Seed Golf is another standout. The company ships most orders within the UK and Ireland using electric vehicles and partners with Pachama, an AI-driven platform that tracks forest conservation projects to offset remaining emissions. Impressively, each golf bag they produce incorporates yarn made from around 27 recycled plastic bottles.

While carbon-neutral manufacturing addresses emissions, ethical supply chains enhance sustainability by tackling environmental and social issues simultaneously.

Ethical Supply Chains in Golf Bag Production

Sustainability doesn’t stop at materials and processes – it extends to how companies source and transport their goods. Ethical supply chains reduce both environmental impact and social inequities. Localized production, for example, cuts transportation emissions and supports regional economies, illustrating how sustainability and community development can go hand in hand.

The Prevented Ocean Plastic program is a prime example of ethical sourcing in action. Since 2020, this initiative has collected over 2.5 billion plastic bottles from coastal areas at risk of pollution. This effort not only prevents waste from entering the ocean but also creates jobs in vulnerable communities. Similarly, MNML Golf focuses on extending the lifecycle of its products, ensuring that equipment stays out of landfills.

These practices showcase how sustainable manufacturing can meet environmental goals while delivering products that align with consumer expectations. From carbon-neutral materials to ethical sourcing, the golf industry is proving that eco-friendly innovation is possible without compromising on quality.

Keep Perfect Golf‘s Sustainable Customization Options

Keep Perfect Golf is embracing eco-conscious production by offering golfers a chance to combine style with sustainability. Their customizable golf bags are designed to reflect personal preferences while maintaining a commitment to environmentally responsible practices. By allowing golfers to choose from a range of sustainable materials and design elements, Keep Perfect Golf provides a refreshing alternative to conventional bags.

Custom Golf Bags Made with Recycled Materials

When it comes to materials, Keep Perfect Golf provides three standout options for crafting custom golf bags. First, there’s Repreve®, a recycled polyester derived from post-consumer plastic bottles. This material not only delivers top-notch performance but also serves as an excellent foundation for unique custom designs. Next, the company uses Seawastex, a recycled nylon made from discarded fishing nets. Known for its impressive strength-to-weight ratio and resistance to wear, it’s a durable choice for golfers seeking reliability. Lastly, recycled ripstop offers a lightweight yet sturdy option, making it perfect for stand and travel bags.

By using recycled polyester and nylon, Keep Perfect Golf significantly reduces plastic waste, minimizes reliance on virgin fossil fuels, and cuts down on energy use compared to manufacturing with new materials.

Eco-Friendly Logo and Design Customization

Beyond sustainable materials, Keep Perfect Golf takes customization to the next level with eco-conscious design options. Golfers can personalize their bags with logos, patterns, and artistic designs, all created with sustainability in mind. Recycled fabrics like SeaWastex nylon and RPET (recycled polyester from plastic bottles) play a key role in these customizations. For a more personal touch, the company offers hand-painted artwork by local artists, which not only supports community artisans but also reduces production waste. Whether it’s embroidered logos or carefully selected color schemes, these options let golfers express their individuality while staying true to their environmental values.

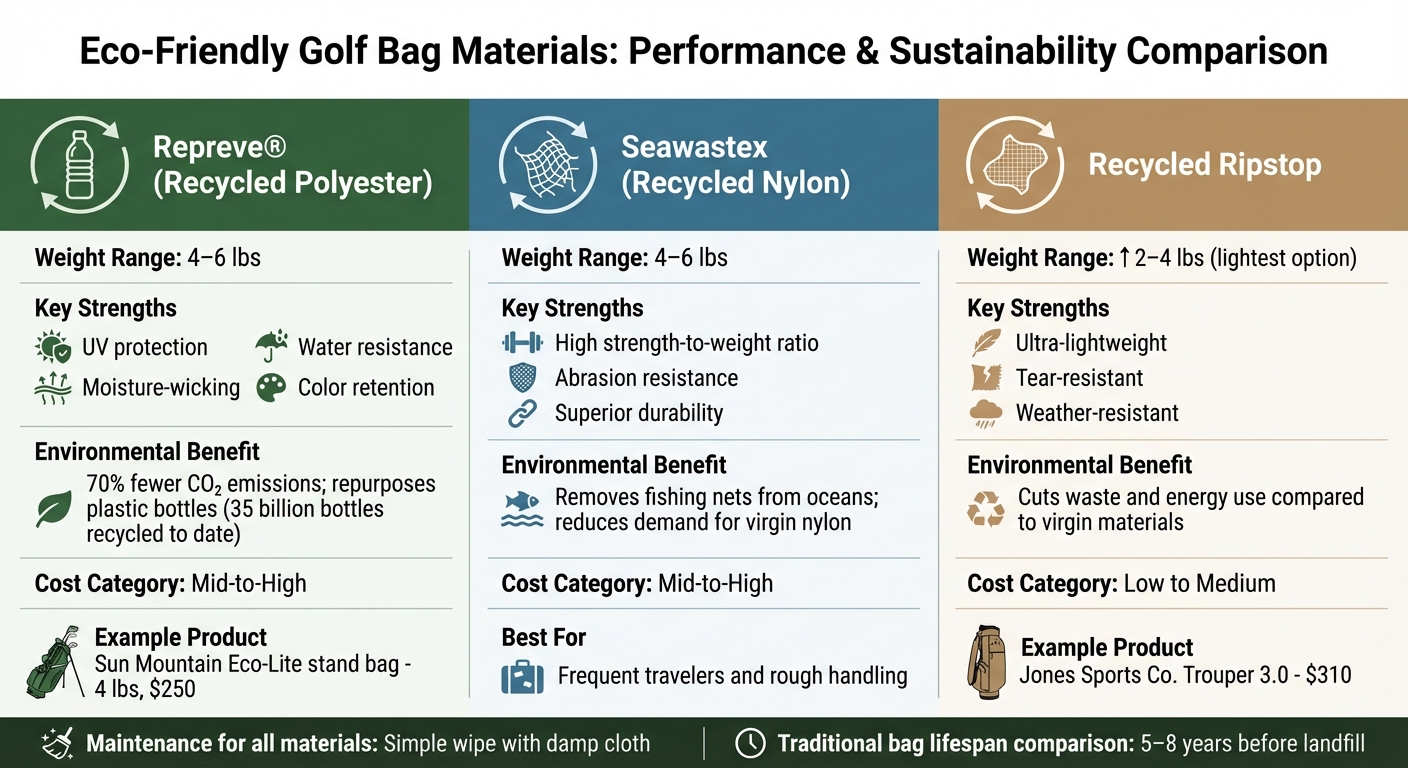

Material Comparison: Eco-Friendly Options for Golf Bags

Eco-Friendly Golf Bag Materials Comparison: Repreve vs Seawastex vs Recycled Ripstop

Comparison Table: Repreve®, Seawastex, and Recycled Ripstop

When considering sustainable materials for golf bags, it’s important to weigh factors like durability, weight, environmental impact, and cost. Each eco-friendly material option brings unique benefits to the table, catering to both performance and sustainability needs.

Repreve® is a recycled polyester made from plastic bottles, offering features like UV protection, water resistance, and moisture-wicking capabilities. By using this material, carbon emissions are reduced by 70%, and over 35 billion plastic bottles have been repurposed so far . Its ability to retain vibrant colors and resist fading makes it a great choice for custom designs with intricate logos or bold colors.

Seawastex, derived from discarded fishing nets, stands out for its impressive strength, high strength-to-weight ratio, and abrasion resistance. This makes it an excellent option for golf bags that face frequent travel or rough handling.

Recycled Ripstop materials are known for being lightweight (typically between 2–4 lbs) and highly tear-resistant. These qualities make them ideal for golfers who prefer carrying their bags while walking an 18-hole course.

| Material | Weight Range | Key Strengths | Environmental Benefit | Typical Cost Category |

|---|---|---|---|---|

| Repreve® (Recycled Polyester) | 4–6 lbs | UV protection, water resistance, moisture-wicking, color retention | 70% fewer CO₂ emissions; repurposes plastic bottles | Mid-to-High |

| Seawastex (Recycled Nylon) | 4–6 lbs | High strength-to-weight ratio, abrasion resistance, durability | Removes fishing nets from oceans; reduces demand for virgin nylon | Mid-to-High |

| Recycled Ripstop | 2–4 lbs | Lightweight, tear-resistant, weather-resistant | Cuts waste and energy use compared to virgin materials | Low to Medium |

For example, Sun Mountain’s Eco-Lite stand bag, made with Repreve® fabric, weighs about 4 lbs and is priced at approximately $250. The cart bag version, slightly heavier at 6 lbs, retails for around $280 . Maintenance for all these materials is simple – just a quick wipe with a damp cloth is enough.

This comparison showcases how these eco-friendly materials contribute to sustainable, high-performance golf bag designs while addressing different needs and preferences.

Conclusion: Moving Toward Sustainable Golf Bag Production

The future of the golf industry depends on embracing environmentally conscious manufacturing practices. Traditional golf bags, with their relatively short lifespan, contribute significantly to landfill waste. Addressing this issue requires a shift toward using materials and methods that reduce environmental harm without compromising quality.

Materials like Repreve®, Seawastex®, and recycled ripstop have emerged as game-changers. These eco-friendly options not only lessen environmental impact but also maintain the durability and performance golfers expect. On top of that, innovations like magnetic closures are improving product longevity, ensuring these bags remain functional for longer periods.

One standout in this movement is Keep Perfect Golf, which is leading the charge with custom golf bags crafted from recycled and biodegradable materials. Their OEM/ODM services allow for logo customization and pattern designs using eco-conscious fabrics. This means golfers and businesses can prioritize sustainability without sacrificing style or quality. Keep Perfect Golf demonstrates how thoughtful design and responsible production can come together to create a greener path forward.

Ethical sourcing is another crucial piece of the puzzle. Many companies are now focusing on sourcing materials locally, with some securing up to 80% of their components from within a 100-kilometer radius. This approach significantly reduces transportation-related emissions. Additionally, take-back programs are gaining traction, offering solutions to manage the end-of-life cycle of golf bags and prevent them from becoming waste.

By combining durable recycled materials, designs that prioritize longevity, and sustainable manufacturing practices, the industry creates a win-win scenario. Golfers enjoy high-performance bags that stand the test of time, while the planet benefits from reduced waste and lower carbon emissions. As Sun Mountain aptly states:

"Sustainability is not only a responsibility but also a privilege for sports to inspire and empower".

FAQs

What are the advantages of using recycled materials in golf bags?

Using recycled materials in golf bags brings notable advantages for both the planet and golfers. By reusing post-consumer plastics and textiles, manufacturers help cut down on waste that could otherwise pollute landfills or oceans. This approach also reduces the carbon footprint tied to production. Materials like RPET (recycled polyester) offer the same durability, water resistance, and lightweight feel as traditional options, ensuring the bag remains practical and easy to handle.

Recycled fabrics can even provide high-end features, such as UV protection and moisture-wicking properties, which safeguard clubs and hold up against outdoor elements. Plus, opting for recycled materials meets the increasing demand for eco-conscious products, giving brands an edge in the market while promoting sustainability – all without compromising on performance or style.

How do biodegradable materials in golf bags help the environment?

Biodegradable materials, such as fibers from banana stems or pineapple leaves, naturally decompose at the end of their lifecycle. This helps cut down on plastic waste and reduces the strain on landfills. Unlike synthetic materials, which can linger in the environment for decades, these fibers break down into organic matter, helping to curb greenhouse gas emissions and lessen overall environmental harm.

What’s even better? Many of these materials come from agricultural by-products, effectively turning waste into useful resources. Take banana fiber, for instance – it’s durable, water-resistant, and sourced from discarded tree stems. This means fewer raw materials are needed. By incorporating these eco-friendly options, golf bag manufacturers can shrink their production’s carbon footprint while giving environmentally-conscious golfers a more sustainable choice.

Why is carbon-neutral manufacturing important for sustainable golf bag production?

Reducing greenhouse gas emissions is a key step in making golf bag production more environmentally friendly. By using energy-efficient methods and offsetting any remaining emissions, manufacturers can significantly lower their impact on the planet and play a role in addressing climate change.

This shift isn’t just good for the environment – it resonates with what consumers are looking for. Golfers are increasingly drawn to brands that emphasize sustainability. Adopting carbon-neutral practices not only strengthens trust and loyalty among eco-conscious players but also keeps manufacturers ahead as the industry leans toward recycled and renewable materials. It’s a smart move to stay aligned with evolving standards while staying competitive.