Golf bag manufacturers are rethinking their processes to meet growing demand for eco-friendly products. Here’s why it matters and how to get started:

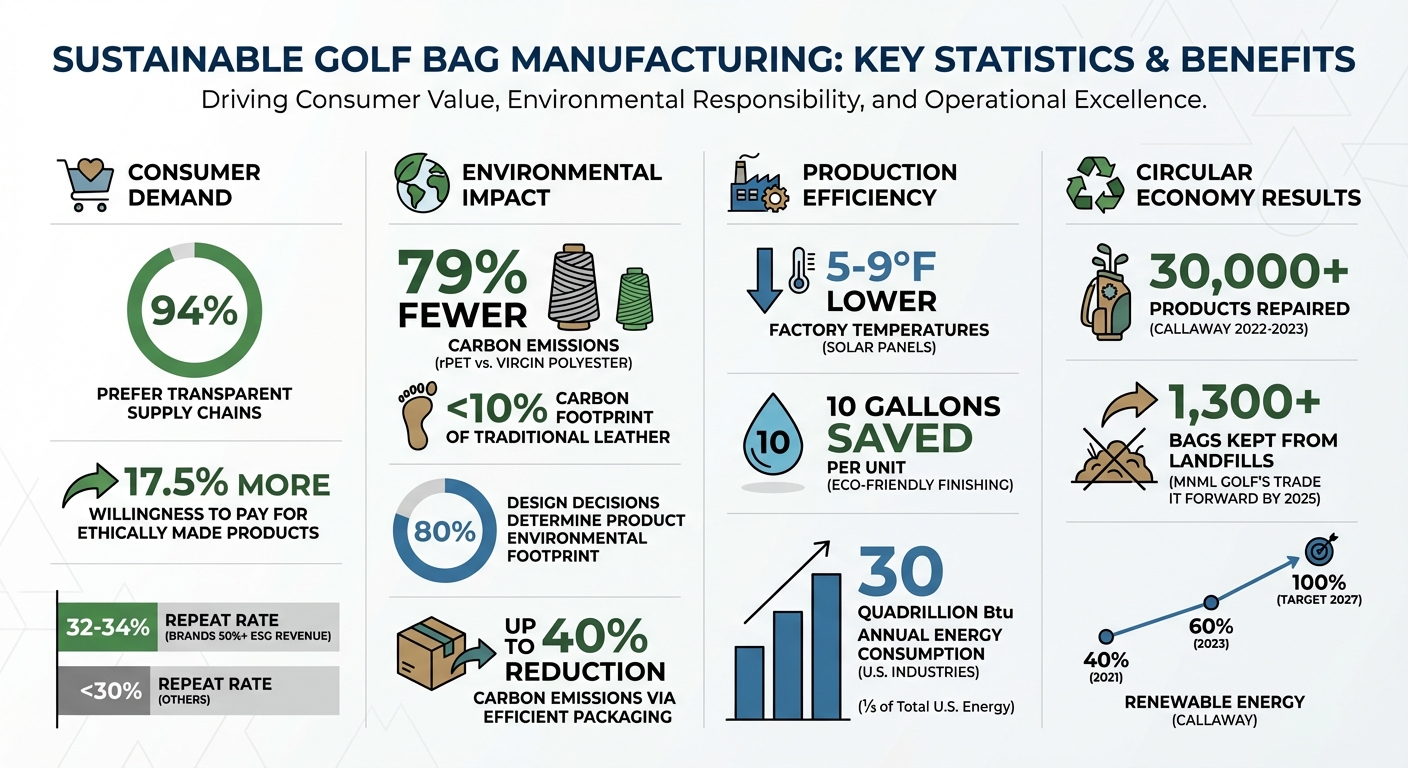

- Consumer demand is shifting: 94% of buyers prefer transparent supply chains, and golfers are willing to pay 17.5% more for ethically made products.

- Eco-friendly designs last longer: Durable, repairable, and modular bags reduce waste and extend product life.

- Materials make a difference: Recycled polyester (rPET), recycled nylon, and plant-based fabrics offer performance and lower carbon footprints.

- Efficient production saves resources: Cutting waste, using renewable energy, and adopting water-saving techniques reduce costs and emissions.

- Packaging and shipping matter too: Recyclable materials and optimized shipping reduce environmental impact and lower expenses.

OEMs can gain a competitive edge by adopting these practices while meeting consumer expectations for sustainable products. Let’s explore the details.

Sustainable Golf Bag Manufacturing: Key Statistics and Impact Metrics

Designing Golf Bags with Eco-Friendly Principles

Core Principles of Eco-Friendly Golf Bag Design

Creating golf bags with sustainability in mind starts with smart design choices. The idea is simple: the longer a bag lasts, the less often it needs to be replaced, which directly reduces waste and environmental strain. When a product is built to last and performs well, it stays in use longer – keeping it out of landfills and in players’ hands.

Another key factor is repairability. For example, between 2022 and 2023, Callaway Golf repaired over 30,000 products through their warranty and repair services, preventing functional bags from ending up in the trash. To make repairs easier, designers can focus on replaceable components. Zippers, which are a common point of failure, can be swapped out for 100% magnetic pocket closures to avoid this issue. Similarly, detachable stand legs and other modular parts can extend the bag’s lifespan by allowing simple replacements when needed.

Modular designs also add versatility. Features like convertible strap systems, which can switch between dual and single configurations, make the bag adaptable for different uses – whether walking the course or using a cart. Removable compartments for electronics are another smart touch, allowing upgrades without compromising the overall structure.

By prioritizing durability, repairability, and modularity, designers can create bags that last longer and reduce environmental impact. The next step? Ensuring that the materials used are both eco-friendly and high-performing.

Maintaining Performance While Using Eco-Friendly Materials

Once the foundation of sustainable design is set, the focus shifts to materials. Using eco-friendly materials doesn’t have to mean compromising on performance. In fact, it’s possible to meet – and even exceed – industry standards while sticking to sustainable options. For instance, 100% recycled Ripstop nylon outperforms standard polyester with its superior tear resistance, offering both durability and environmental benefits.

Advances in material technology are making it easier to combine sustainability with functionality. Take recycled nylon fibers sourced from discarded fishing nets through programs like Seawastex – they provide the strength needed for cart and stand bags while reducing reliance on virgin fossil fuels. For lightweight Sunday bags, carbon fiber frames are a great choice. They cut down on weight without sacrificing structural integrity, making these bags easier to carry and more energy-efficient to ship.

The challenge lies in finding the right balance. Lightweight materials are ideal for reducing energy consumption and improving portability, but they must also hold up to the wear and tear of regular use. By carefully selecting and testing eco-conscious materials, manufacturers can ensure their bags perform just as well – if not better – than traditional options.

sbb-itb-4fa7e8b

Choosing Eco-Friendly Materials for Golf Bags

Recycled and Eco-Friendly Material Options

When crafting golf bags with sustainability in mind, recycled polyester (rPET) is an excellent choice for shells and exteriors. Made from post-consumer plastic bottles, rPET is lightweight, water-resistant, and matches virgin polyester in performance – all while generating 79% fewer carbon emissions during production. As Orla Kiely highlights in their "Bags for Good" collection:

"There is no difference between virgin polyester and recycled polyester in terms of performance".

Another great option is recycled nylon, especially when sourced from ocean waste. This not only reduces the need for virgin fossil fuels but also helps tackle marine pollution. For a more natural touch, Harris Tweed, made entirely from wool, is windproof, waterproof, and biodegradable, offering protection without relying on chemical treatments.

For weatherproofing, organic cotton treated with plant-based waxes works well for bag shells. However, for areas that need to withstand more wear and tear, such as linings, polycotton blends are preferred. As Fyfe Golf explains:

"The strength of polycotton is far greater than 100% organic cotton linings which is required to ensure durability and function for these products".

When it comes to padding, lyocell wadding is a biodegradable alternative to synthetic foam. For handles and trims, recycled leather is a smart option, boasting less than 10% of the carbon footprint of traditional leather. Alternatively, innovative vegan leathers like Piñatex, Desserto, or AppleSkin, which repurpose agricultural waste, offer stylish and sustainable choices. Even the smallest details, like labels, matter – recycled polyester is a better option than organic cotton, as it resists soiling from perspiration and club contact.

With these material options in mind, ensuring they meet environmental and industry standards is the next crucial step.

Material Certifications and Supply Chain Traceability

Selecting eco-friendly materials is only part of the equation – verifying their sustainability is equally important. The Global Recycled Standard (GRS) certifies that products contain at least 20% recycled material and ensures traceability, environmental compliance, and social responsibility at every stage of production. To maintain a secure chain of custody, request transaction certificates (TCs) from third-party auditors for each shipment.

For organic materials, certifications like the Organic Content Standard (OCS) or Better Cotton Initiative (BCI) provide assurance of sustainable practices. If wool is part of the design, look for the Responsible Wool Standard (RWS), which guarantees animal welfare and sustainable land management. Advanced traceability tools like AWARE™ go a step further, embedding tracer particles in fibers and utilizing blockchain technology to create a digital record of the material. This not only prevents greenwashing but also ensures materials remain authentic throughout the supply chain.

Looking ahead, the Textile Exchange is consolidating its individual standards (GRS, RCS, OCS) into a unified Materials Matter Standard, which will be mandatory by December 31, 2027. Preparing for this transition now can streamline certification processes and ensure compliance across all material types.

Reducing Waste and Energy Use in Production

Reducing Material Waste in Cutting and Sewing

The cutting process in manufacturing often leads to a lot of fabric waste. To tackle this, the DOWNTIME framework highlights eight types of waste that can undermine efficiency: Defects, Overproduction, Waiting, Not properly utilizing talent, Transportation, Inventory excess, Motion waste, and Excess processing. By systematically addressing these areas, manufacturers can significantly cut down on scrap rates.

Just-in-Time (JIT) production is a game-changer in this space. This pull-based method ensures that golf bags are only made when orders are received, which minimizes overproduction and raw material waste. When paired with strict quality control measures at every stage – cutting, stitching, and finishing – it helps reduce defective items that often lead to unnecessary waste. Additionally, conducting waste audits on the cutting floor can uncover patterns and opportunities to repurpose leftover materials.

Preventive maintenance and real-time digital communication are also key in reducing waste. These strategies minimize machine breakdowns and ensure technicians have quick access to custom specifications, preventing unnecessary delays and material loss. On top of that, efficient inventory tracking prevents specialized fabrics and components from expiring or becoming obsolete before they’re used.

Improving Energy and Resource Efficiency

Reducing fabric waste is just one part of the equation – optimizing energy use is another crucial step toward sustainable production. U.S. industries consume roughly 30 quadrillion Btu of energy annually, accounting for nearly a third of the nation’s total energy use. For golf bag manufacturers, adopting the ISO 50001 Energy Management standard provides a structured way to monitor energy consumption and drive continuous improvement.

BIG MAX, a leading golf bag manufacturer, has made impressive strides in this area. They installed nearly 40,000 square meters (about 430,000 square feet) of solar panels at their facility, a move that not only powers their operations but also lowers factory temperatures by 5 to 9 degrees Fahrenheit. This reduction in temperature cuts the energy needed for air conditioning. Thomas Reiter, Founder and CEO of BIG MAX, shared another important milestone:

"Last year we decided to remove the use of solvents from our cart equipment… this changeover is also said to have been accompanied by more cost-effective production".

Switching to solvent-free powder coating for finishing processes has been another transformative step. This method eliminates toxic pollutants and lowers disposal costs. Additionally, eco-friendly finishing techniques can save up to 10 gallons of water per unit. Collecting rainwater from factory roofs further reduces reliance on municipal water supplies, contributing to more sustainable resource use.

Eco-Friendly Packaging and Shipping for Golf Bags

Recyclable and Reusable Packaging Materials

Once manufacturers have fine-tuned production efficiency and minimized waste, it’s time to tackle the environmental footprint of packaging and shipping. The right packaging materials can cut carbon emissions by up to 40% when shipping golf bags. For outer containers, recycled cardboard and corrugated boxes are ideal. Pair these with Kraft paper for internal cushioning. Ditch plastic bubble wrap in favor of paper-based fillers, and swap plastic sleeves for textile pouches to safeguard the product during transit.

In 2022, MNML Golf founder Sam Goulden introduced the "Trade It Forward" program in the U.S. Customers receive their new MNML bag, crafted from recycled RePet, and return their old golf bag in the same shipping box. With a pre-paid dispatch note, the old bag is sent to the Junior Foundation of the Southern California Golf Association. By 2025, this program had kept over 1,300 bags out of landfills.

To ensure full recyclability, use soy-based, vegetable-based, or water-based inks on packaging. Water-activated paper tape is another great alternative to traditional plastic tape. Lynx Golf, as part of its UN Global Compact commitment, eliminated single-use plastics in shipping. They even include a packet of flower seeds in each box to promote bee conservation.

Maximizing Shipping Efficiency

Sustainability isn’t just about materials – it’s also about smart packaging design. Efficiently sized packaging reduces both costs and environmental impact. By designing boxes to be just large enough, you can lower dimensional-weight fees from carriers like USPS, UPS, and FedEx. This can sometimes reduce volumetric weight charges by as much as a third. Custom corrugated boxes, such as E-flute or Bux Board, help achieve a snug fit, cutting down on filler use and improving load efficiency.

Apple’s 2020 decision to remove the iPhone 12 power adapter serves as a prime example. By shrinking the packaging, they fit 70% more boxes on each shipping pallet. This move not only slashed carbon emissions but also reportedly boosted profits by $6.5 billion due to reduced logistics and packaging costs [KatanaMRP, 2024]. Golf bag manufacturers can apply similar strategies by using lighter materials and flat-pack designs, which reduce warehouse space needs and improve transport efficiency, ultimately lowering fuel consumption per unit.

For U.S. manufacturers, sourcing packaging from domestic suppliers offering FSC-certified or recycled materials can further cut transport emissions. Regular logistics audits are also essential. These can help identify unnecessary product movement, consolidate shipments, and determine if products can be shipped without an additional outer box, saving both materials and space.

Tracking and Improving Your Eco-Friendly Performance

Key Metrics for Measuring Eco-Friendly Performance

Once you’ve implemented design and production changes, the next step is keeping a close eye on your eco-friendly performance. Start with material composition – track the percentage of recycled materials like rPET and recycled leather in your products. For instance, recycled leather has a carbon footprint that’s less than 10% of traditional leather. Also, keep tabs on how much of your materials are locally sourced; shorter supply chains mean lower transportation emissions.

Resource consumption is another critical area to monitor. Measure energy usage per unit, water consumption, and emissions during production. Some companies use tools like the Eco-indicator 99 framework to combine these factors into a single sustainability score. Don’t overlook material waste and how effectively you’re implementing circular economy practices. Social metrics matter too – track gaps in living wages and adherence to labor standards. Interestingly, brands that generate over half of their revenue from ESG-related products often see higher repeat purchase rates (32-34%) compared to those that don’t (under 30%).

These metrics provide a strong foundation for ongoing evaluation and improvement.

Regular Review and Compliance with Standards

Once you’ve gathered this data, use it to fine-tune your sustainability initiatives. Consider setting up a quarterly Executive Sustainability Committee to review your strategies, allocate resources, and address risks. For example, in 2023, Topgolf Callaway Brands updated its auditing process for Tier I suppliers across Callaway Golf, OGIO, and TravisMathew brands to align with the SMETA protocol, enabling better benchmarking against industry standards. Frameworks like the Global Reporting Initiative (GRI) Standards can help you identify which environmental and social factors are most critical for long-term success.

Conduct risk assessments every two years with third-party consultants to categorize sustainability risks. Make compliance with your Restricted Substances List (RSL) a contractual requirement for all suppliers, ensuring alignment with both EU REACH and California Proposition 65 regulations. For energy tracking, tools like the ENERGY STAR Industrial Benchmarking Tools can help you set baselines and define reduction goals. For example, Callaway Golf increased renewable energy use at its corporate headquarters from 40% in 2021 to 60% in 2023, with a goal of reaching 100% by 2027.

Automating your data collection process can make a big difference. Transition from manual tracking to automated systems for monitoring waste. This not only ensures compliance with regulations but also gives you real-time insights into your environmental impact. The World Economic Forum has developed 21 core ESG metrics and 34 additional disclosures to help standardize sustainability reporting across industries. These tools and frameworks can guide your efforts toward measurable, transparent progress.

This Bag Fixes EVERYTHING Wrong with Golf Bags!

Conclusion: Building a Better Future for Golf Bag Manufacturing

Sustainable practices in golf bag manufacturing offer more than just compliance with regulations – they provide a clear edge in the market. Remarkably, design decisions alone can determine up to 80% of a product’s environmental footprint, making every choice along the way matter significantly.

The strategies discussed in this guide – like shifting to recycled polyester, using organic cotton, adopting closed-loop water systems, and embracing renewable energy – aren’t just theoretical. They’re practical, proven methods already making a difference in the industry. And these steps don’t just benefit the planet; they bring tangible advantages to businesses as well.

"We believe performance and sustainability can co-exist." – Minimal Golf

This sentiment perfectly reflects the direction of modern manufacturing. Quality and sustainability no longer stand at odds. By focusing on durable products and circular economy principles, companies can strengthen customer loyalty while contributing to a healthier planet.

FAQs

What are the best sustainable materials for making golf bags?

The most environmentally friendly materials for golf bags include recycled plastics and plant-based fibers. For instance, recycled fabrics like ripstop, crafted from post-consumer PET bottles, offer durability and weather resistance while slashing carbon emissions by up to 70%. Plus, these materials avoid the use of new petroleum-based fibers, making them a greener choice.

Plant-based options such as banana fiber, pineapple leaf fiber (PALF), jute, lyocell, and organic cotton are another great alternative. These textiles are biodegradable and often repurpose agricultural byproducts like banana stems or pineapple leaves. They also require less water and fewer chemicals compared to synthetic materials, making them a more sustainable option for golf bag production.

A standout material is recycled polyester (rPET). It retains the lightweight properties of traditional polyester while reducing energy consumption by about 50% and cutting carbon emissions by 70%. By blending recycled or plant-based materials, manufacturers can create golf bags that are durable, meet performance expectations, and cater to the rising demand for eco-conscious sports gear.

What steps can OEMs take to make their supply chains more sustainable?

Original Equipment Manufacturers (OEMs) looking to reduce their environmental impact can start by examining the entire lifecycle of their products. Tools like life-cycle assessments (LCA) are incredibly useful for pinpointing areas where carbon emissions can be cut, waste reduced, and eco-friendly materials prioritized. For instance, swapping out conventional materials for recycled or bio-based alternatives can significantly shrink the carbon footprint without sacrificing quality or performance.

Another important step is designing products with sustainability in mind. By adopting a circular approach, OEMs can create golf bags with modular parts, making them easier to repair, recycle, or even repurpose. Programs like take-back or recycling initiatives can further extend the life of materials, keeping them in use and out of landfills.

Collaboration with suppliers is also critical. Setting clear standards for material sourcing, energy usage, and waste management ensures everyone in the supply chain is on the same page. Partnering with suppliers who carry recognized sustainability certifications and conducting regular audits can help maintain accountability. This team effort not only supports environmental goals but also meets the growing demand from consumers for greener practices.

What are the advantages of designing modular and repairable golf bags?

Designing golf bags with modular and repairable features brings practical benefits for both the environment and your wallet. By making components like straps, pockets, or internal stands replaceable or repairable, the lifespan of the bag is significantly extended. This means less waste and a reduced need for raw materials, aligning with eco-conscious practices and the idea of a circular economy.

For manufacturers, this approach can cut production costs since fewer resources are needed to replace parts rather than creating entirely new bags. Golfers also come out ahead, saving money by repairing or upgrading their bags instead of purchasing new ones. Plus, modular designs open the door for customization – think features like a solar charging pocket or upgraded stands. These additions not only cater to the demand for cutting-edge, high-performance gear but also keep the core product recyclable.