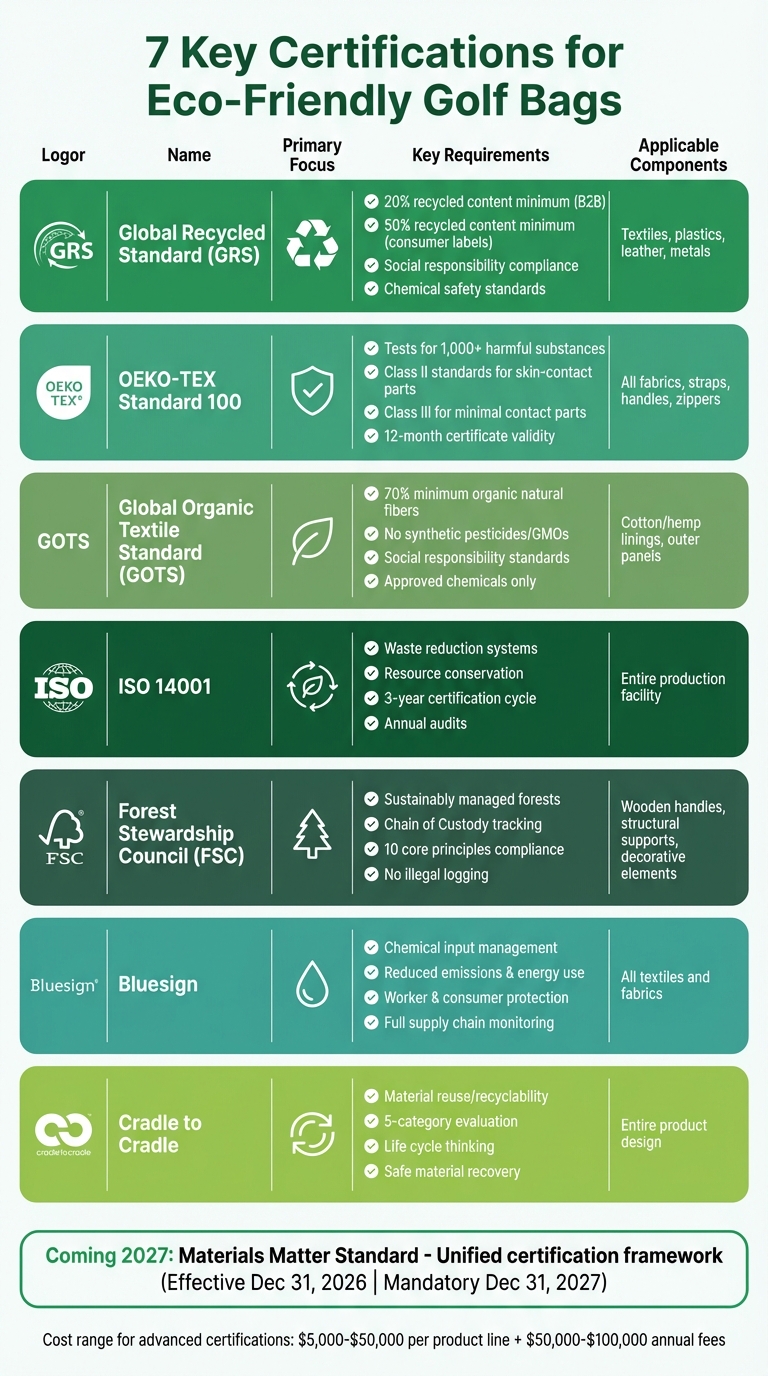

The shift towards eco-friendly golf bags is driven by certifications that ensure products meet strict environmental, safety, and ethical standards. These certifications verify claims about recycled materials, chemical safety, and responsible production practices, providing transparency and accountability for both manufacturers and consumers. Key certifications include:

- Global Recycled Standard (GRS): Tracks recycled content and enforces social and chemical safety.

- OEKO-TEX Standard 100: Tests materials for over 1,000 harmful substances to ensure safety.

- Global Organic Textile Standard (GOTS): Certifies organic fibers and sustainable production.

- ISO 14001: Focuses on environmental management systems to reduce waste and resource use.

- Forest Stewardship Council (FSC): Ensures wood components are sourced responsibly.

- Bluesign: Reduces environmental impact in textile production.

- Cradle to Cradle: Promotes material reuse and circular design.

These certifications not only validate eco-friendly claims but also push the industry toward better practices. For instance, the upcoming Materials Matter Standard, effective by 2027, will unify criteria for recycled content and ethical manufacturing. Manufacturers and brands can use these certifications to align with sustainability goals, reduce costs, and meet rising consumer expectations for transparency and safety.

7 Key Eco-Friendly Golf Bag Certifications Comparison Guide

Global Recycled Standard (GRS) for Recycled Materials

The Global Recycled Standard (GRS) ensures that products made with recycled materials meet strict guidelines for social responsibility, environmental protection, and chemical safety. This certification guarantees that eco-friendly golf bags adhere to high standards throughout every step of production. Here’s a closer look at how the certification works and what it requires.

GRS Requirements and Verification Process

The GRS employs a two-tier certification system. Products containing at least 20% recycled content can earn business-to-business certification, while those with 50% or more recycled content can display consumer-facing labels.

To ensure transparency, the certification relies on the Content Claim Standard (CCS), which tracks materials from recycling facilities to the final product. Each facility involved in the production process must hold a valid Scope Certificate (SC), and every shipment must come with a Transaction Certificate (TC) for verification.

In addition to material tracking, the GRS enforces compliance with International Labor Organization (ILO) standards and prohibits the use of hazardous chemicals in production. Independent third-party auditors conduct annual inspections to evaluate energy use, water consumption, and waste management practices. This rigorous system ensures that claims about recycled content are accurate and trustworthy.

Using GRS Materials in Golf Bags

Golf bag manufacturers can incorporate GRS-certified materials into a variety of components, such as textiles, plastics, leather, and metals. One of the most common applications is using recycled polyester or nylon fabrics made from post-consumer plastic bottles. Both recycled factory scraps and post-use products qualify as recycled materials under the ISO definition followed by the GRS.

To meet certification requirements, manufacturers must ensure their products meet the recycled content threshold. For example, a 5-lb stand bag would need to include at least 2.5 lbs of certified recycled materials, covering elements like fabric panels and zippers.

The industry is also preparing for the adoption of a new Materials Matter Standard. Released on December 12, 2025, this new standard will become effective on December 31, 2026, and mandatory by December 31, 2027. Manufacturers using GRS-certified materials should begin aligning with these guidelines to maintain their certifications.

This detailed certification process not only supports the use of recycled materials but also lays the groundwork for integrating additional eco-friendly standards into golf bag production.

OEKO-TEX Standard 100 for Safe Textiles

OEKO-TEX Standard 100 is an independent certification system designed to ensure that every textile component is free from harmful chemicals. With a focus on human health and safety, it tests materials against a stringent list of over 1,000 harmful substances. For a golf bag to receive this certification, every part – whether it’s the outer fabric or smaller accessories – must pass detailed chemical safety tests. The certification specifically targets hazardous substances that could pose risks through inhalation, skin contact, or even saliva exposure.

What makes this system particularly efficient for manufacturers is its modular approach. If individual components, like zippers or straps, are already OEKO-TEX certified, the testing requirements for the final product can be waived, reducing costs. This streamlined process connects manufacturers to a global network of over 35,000 certified suppliers, making it simpler to source safe materials.

Golf bags generally fall into two categories under OEKO-TEX: Class II (components like straps and handles that come into direct contact with skin) and Class III (parts like the main bag body that have minimal or no skin contact). Class II components are held to stricter chemical limits due to their frequent interaction with skin.

OEKO-TEX Standard 100 Testing Process

The OEKO-TEX testing process is thorough, ensuring materials meet the highest safety standards. It involves six key steps: an online application, material sample submission, verification, development of a customized testing plan, an on-site production facility inspection, and finally, the issuance of a certificate. During testing, materials are analyzed for harmful substances like heavy metals, organic compounds, toxic dyes, pigments, and residues such as PFCs and flame retardants. To keep up with scientific advancements and global regulations, the certification’s limits are updated annually. This ensures compliance with international standards like the REACH directive, CPSIA, and the ECHA-SVHC candidate list. Certificates are valid for 12 months, after which manufacturers must renew and re-test their products.

For golf bags made with recycled textiles, OEKO-TEX requires at least 20% recycled content along with a validated quality management system. Since recycled materials often come from diverse sources, they may undergo more frequent testing to maintain safety standards. Consumers and manufacturers can verify the authenticity of an OEKO-TEX label by scanning the QR code or entering the certificate number into the OEKO-TEX Label Check tool.

Benefits of OEKO-TEX Certification

OEKO-TEX certification offers a dual advantage: it prioritizes personal safety while also contributing to environmental health. By restricting harmful chemicals in textiles, it reduces the chemical footprint of golf bags throughout their lifecycle. For golfers, this means that high-contact areas like straps and handles are safe for long-term use.

For manufacturers, the modular system is a game-changer. Pre-certified components simplify production, cutting both costs and time to market. When crafting custom golf bags, using OEKO-TEX-certified zippers, linings, and straps ensures compliance with strict safety standards without the need for additional testing. This rigorous chemical safety framework aligns seamlessly with other eco-certifications, making it an essential consideration in modern golf bag production.

Global Organic Textile Standard (GOTS) for Organic Fibers

Building on the principles set by certifications like GRS and OEKO-TEX, the Global Organic Textile Standard (GOTS) ensures eco-conscious production by certifying organic fibers at every stage of manufacturing.

To achieve GOTS certification, products must include at least 70% certified organic natural fibers, which are cultivated without synthetic pesticides, herbicides, or GMOs. For golf bags, this standard applies to components such as outer fabrics, linings, and decorative elements, though it excludes leather.

GOTS certification covers every step of the production process – from harvesting and processing to manufacturing, packaging, and distribution. It imposes strict limits on chemical inputs, allowing only approved, non-toxic substances, while also mandating proper wastewater treatment. Beyond environmental considerations, GOTS includes social responsibility requirements, such as banning child and forced labor, promoting gender equality, and ensuring worker safety. With over 4 million employees working in GOTS-certified facilities worldwide, this standard underscores a strong commitment to ethical and sustainable manufacturing practices, making it a key factor in the use of certified organic fibers for golf bag design.

Organic Materials in Golf Bags

In practice, GOTS-certified organic materials like cotton and hemp are ideal for golf bags, particularly for interior linings and outer panels. These materials provide a soft, chemical-free surface while offering durability and resistance to mold. To display the GOTS logo, textile components must meet the 70% organic content requirement, with higher-grade certifications demanding 95% organic content. Additionally, accessories such as zippers and buttons must adhere to ecological standards outlined by GOTS. When creating custom golf bags with organic materials, it’s important to ensure that suppliers have valid GOTS certification for their specific operations. This can be verified through the GOTS Certified Suppliers Database.

GOTS Supply Chain Requirements

For a product to carry the GOTS logo, every stage of production – from raw material processing to final assembly – must comply with GOTS standards. Even outsourcing tasks like stitching to uncertified contractors can disqualify the product from certification.

"The GOTS logo can only be applied to the final product if all stages comply with the GOTS criteria. Therefore, all processors, manufacturers, and traders of textiles need to be certified." – TÜV Rheinland

The certification process is divided into four scopes:

- Scope 1: Mechanical textile processing and manufacturing, such as cutting and sewing.

- Scope 2: Wet processing and finishing, including dyeing and fabric treatments.

- Scope 3: Trading operations.

- Scope 4: Approval of dyes and textile auxiliary agents.

Manufacturers must determine which scope applies to their operations and undergo inspections by accredited bodies like TÜV Rheinland or Control Union. Once certified, entities are required to pay a license fee to use the GOTS logo on their products. Ongoing compliance is ensured through regular inspections, maintaining high standards for environmental and social responsibility throughout the production cycle.

ISO 14001 for Environmental Management

ISO 14001 outlines a framework for implementing an Environmental Management System (EMS) in manufacturing facilities, helping golf bag producers cut waste, conserve resources, and improve efficiency. Globally, over 300,000 certifications have been issued. This certification operates on a three-year cycle, with annual audits and full recertification in the third year.

"ISO 14001 is an internationally recognized standard that helps organizations to realize the benefits of making environmental management a fundamental operating principle." – NSF

For golf bag manufacturers, the standard highlights areas with significant environmental impact. For example, fabric cutting may produce excess scrap, while dyeing processes often require substantial water and energy. These practices are central to the features outlined below.

ISO 14001 Core Features

ISO 14001 provides a structured approach to identifying, assessing, and managing environmental risks. It emphasizes leadership involvement and aligns with ISO 9001 to integrate environmental and quality management systems. To achieve certification, manufacturers must conduct a gap analysis to compare current practices with ISO 14001:2015 requirements. This is followed by implementing the EMS, conducting internal audits, management reviews, and a final external audit. The standard is available for CHF 155, while a small to medium enterprise (SME) package, which includes a practical guide, costs approximately CHF 198.

"Through environmental management systems, companies can systematically identify, evaluate, manage, and improve environmental aspects, thereby effectively managing environmental risks." – Hyosung TNC

ISO 14001 in Golf Bag Production

ISO 14001-certified facilities focus on optimizing resource use and minimizing environmental impact across production processes. This includes reducing waste, conserving energy and water, complying with regulations, and enhancing brand credibility. The benefits for golf bag manufacturing are outlined below.

| ISO 14001 Benefit | Impact on Golf Bag Manufacturing |

|---|---|

| Waste Reduction | Minimizes fabric scrap during cutting and assembly. |

| Resource Conservation | Reduces energy and water usage in production. |

| Regulatory Compliance | Ensures adherence to environmental laws. |

| Risk Management | Identifies pollution and supply chain issues early. |

| Brand Reputation | Demonstrates eco-friendly practices to stakeholders. |

"ISO 14001 provides assurance that the environmental impact of operations is being measured and improved." – FibreGuard

When sourcing materials for custom golf bags, manufacturers should assess the environmental practices of their suppliers, such as those providing fabrics and components, to align with the organization’s goals and risk management strategies. Partnering with suppliers already certified under ISO 14001:2015 ensures accountability throughout the product lifecycle. By adopting ISO 14001, golf bag producers not only enhance operational efficiency but also solidify their commitment to sustainability at every step.

sbb-itb-4fa7e8b

Forest Stewardship Council (FSC) Certification for Wood Components

In the push for greener manufacturing, FSC certification plays a key role in ensuring sustainable practices extend to the wood components used in golf bags. This certification guarantees that the wood comes from responsibly managed forests. For golf bags, this might include wooden handles, structural reinforcements, or decorative touches. FSC certification stands on two core pillars: Forest Management certification, which ensures forests are sustainably managed, and Chain of Custody certification, which tracks the material throughout its journey in the supply chain.

"FSC certification ensures that products come from responsibly managed forests that provide environmental, social and economic benefits." – Forest Stewardship Council

By sourcing FSC-certified wood, manufacturers avoid materials linked to illegal logging or violations of human and traditional rights. This certification is already prevalent in other sports equipment, like skis and wetsuits, making it a natural choice for eco-conscious golf bag components. These rigorous standards set the foundation for the FSC management and supply chain requirements discussed below.

FSC Standards for Forest Management

FSC-certified forests follow 10 essential principles, including compliance with laws, respect for Indigenous Peoples’ rights, and maintaining or restoring ecosystems. These principles often go beyond local legal requirements.

"Every FSC label stands for sustainable sourcing that puts forests and people first." – Forest Stewardship Council

Research shows that FSC-certified Douglas fir forests store more carbon than non-certified ones. Additionally, the certification bans harmful chemicals like atrazine and protects habitats for vulnerable species, such as the Cascade torrent salamander, even in cases where legal protections don’t exist. These stringent practices ensure that wood used in golf bags meets high environmental and ethical standards.

Using FSC-Certified Wood in Golf Bags

Golf bag makers can incorporate FSC-certified wood into various components, such as structural supports, dowel rods for shaping, or decorative elements like wooden handles and tags. To maintain the certification’s integrity, manufacturers must obtain Chain of Custody certification, which tracks the wood from its source to the final product.

When sourcing wood, manufacturers can choose FSC 100%, which guarantees all materials come from responsibly managed forests, or FSC Recycled, which uses reclaimed wood to reduce the need for new harvesting. Every supplier along the production chain must hold Chain of Custody certification to ensure the FSC claim remains intact from start to finish. Additionally, brands selling certified golf bags must also be certified to make product-specific claims.

"FSC forest management certification confirms that the forest is being managed in a way that preserves biological diversity and benefits the lives of local people and workers, while ensuring it sustains economic viability." – ReSOURCE

Bluesign and Cradle to Cradle Certifications

When it comes to sustainability, certifications like Bluesign and Cradle to Cradle go beyond just material safety and resource efficiency. They tackle broader environmental and production impacts, ensuring products are made with care for both the planet and the people involved.

Bluesign: Reducing Production Impact

Bluesign certification, managed by bluesign technologies, monitors the entire textile supply chain – from the chemicals used to the finished product. What sets Bluesign apart is its proactive approach to pollution, focusing on managing chemical inputs right from the start. This protects workers, consumers, and the environment by preventing contamination before it happens.

Recent reports highlight impressive results from Bluesign-certified processes, including reduced emissions, lower energy and water usage, and increased reliance on renewable energy sources. The certification applies to both fabrics and components used throughout the supply chain. When sourcing materials, you’ll find labels such as "Contains materials that meet the bluesign criteria" or "Product meets the bluesign criteria" to guide your choices.

"By managing inputs rather than relying solely on output testing, bluesign helps prevent pollution at the source." – bluesign

While Bluesign focuses on production efficiency, Cradle to Cradle takes on the challenge of designing products that can be reused or recycled at the end of their life.

Cradle to Cradle: Designing for Material Reuse

Cradle to Cradle Certified emphasizes circularity, aiming to create products that are safe to reuse or recycle. This certification evaluates materials and products across five categories, promoting a circular economy where resources are optimized and waste is minimized.

"Cradle to Cradle Certified® is a Type I environmental label… that identifies products designed for a safe, circular, and responsible economy, recognizing achievements across multiple sustainability categories based on life cycle thinking." – Cradle to Cradle Products Innovation Institute

Together, Bluesign and Cradle to Cradle offer a comprehensive approach to sustainability. Bluesign ensures that products, such as golf bags, are manufactured with minimal resource use and safe chemicals. Meanwhile, Cradle to Cradle focuses on making sure these products are designed for material recovery at the end of their lifecycle. However, pursuing these certifications comes at a cost, ranging from $5,000 to $50,000 per product line, with annual fees between $50,000 and $100,000.

Custom Golf Bag Design with Certified Materials

Choosing Certifications for Custom Golf Bags

Designing custom golf bags goes beyond aesthetics – it’s about aligning with your brand’s environmental and ethical values. The first step? Choosing the right certifications to reflect your sustainability goals. If recycled materials and traceability are your focus, the Global Recycled Standard (GRS) is a strong contender. For brands prioritizing organic fibers, the Global Organic Textile Standard (GOTS) ensures compliance from harvesting to environmentally conscious manufacturing practices.

"The GRS includes a higher (50%) minimum recycled content percentage and additional social and environmental requirements related to processing and chemical use." – Textile Exchange

When consumer safety is a priority, OEKO-TEX certification ensures that every component is tested for over 1,000 harmful substances. For those emphasizing sustainable production processes, Bluesign certification focuses on reducing environmental impact while maintaining material performance.

Before finalizing your choice, verify the authenticity of your suppliers’ certifications. Tools like the OEKO-TEX Label Check or QR code scans can confirm their current status. Additionally, keep an eye on the upcoming Materials Matter Standard, which will consolidate various material-specific certifications into a single framework by December 31, 2027. By integrating these certifications into your custom golf bag design, you ensure that every element aligns with your brand’s sustainability promise.

Working with Keep Perfect Golf for Certified Production

Once you’ve identified the certifications that suit your brand, Keep Perfect Golf can help bring your vision to life. Their OEM/ODM services are designed to integrate certified materials seamlessly into every step of the custom golf bag production process. From the start, you have the option to source components that already carry certifications like GRS or OEKO-TEX, which can streamline the process and reduce testing costs.

Throughout production, Keep Perfect Golf ensures transparency and compliance by meticulously tracking certified materials. Transaction certificates follow materials from raw inputs to the finished product, maintaining certification integrity at every stage. Their quality assurance measures document every step, ensuring that all social, environmental, and chemical requirements are met.

Keep Perfect Golf offers a comprehensive solution – covering design, sampling, production, inspection, packaging, and global delivery. At the same time, they adhere to the rigorous standards set by certifications like GRS. To ensure compliance, their production facilities undergo regular third-party audits conducted by independent certification bodies.

For brands working with Keep Perfect Golf, be prepared for on-site inspections to maintain certification standards. Their direct factory model provides greater control over material sourcing and manufacturing, making it easier to meet the strict requirements of certifications while delivering high-quality custom golf bags.

Conclusion

When it comes to eco-friendly golf bags, certifications carry far more weight than vague claims about being "recycled" or "organic." Standards like the Global Recycled Standard (GRS) and OEKO-TEX Standard 100 ensure transparency and accountability, helping consumers and manufacturers alike separate genuinely sustainable products from superficial greenwashing. With OEKO-TEX certification and rigorous testing protocols, these frameworks provide a dependable way to uphold responsible production practices.

These certifications do more than confirm current practices – they actively push the industry toward unified sustainability benchmarks. For instance, the Materials Matter Standard, set to take effect on December 12, 2025, will become mandatory by December 31, 2027. This standard will establish consistent criteria for assessing environmental and social impacts, simplifying certification processes while maintaining high standards for recycled content, chemical safety, and ethical manufacturing.

Before finalizing your product design, double-check that all supplier certifications are in place . If components such as fabrics, zippers, threads, and other accessories are already certified, you might save on testing costs by leveraging modular certification systems. For products incorporating recycled materials, keep in mind that the GRS requires at least 50% recycled content for consumer-facing labels, though business-to-business applications can begin with as little as 20%.

FAQs

What are the advantages of choosing golf bags made with GRS-certified materials?

Golf bags crafted from GRS-certified materials come with some impressive perks. First off, they include a verified amount of recycled content, which helps cut down on waste and minimizes overall impact on the planet. Plus, these materials meet rigorous social and environmental processing standards, ensuring they’re made with ethical practices in mind.

Another big win? GRS certification ensures transparency and traceability across the supply chain. This means you can trust that the materials used are responsibly sourced. Opting for GRS-certified golf bags is a smart way to contribute to sustainability without compromising on durability or quality.

What does OEKO-TEX certification mean for the safety of golf bag materials?

OEKO-TEX certification, like the STANDARD 100, guarantees that every component of a golf bag – whether it’s the fabric, threads, or zippers – has undergone extensive testing for more than 1,000 harmful substances. This ensures the materials are safe for human use, with even stricter standards for items that come into direct contact with the skin.

Opting for golf bags with OEKO-TEX certification means you’re choosing products made with materials that prioritize safety. These bags not only reduce potential health risks but also avoid harmful chemicals that could impact the environment.

What makes the Materials Matter Standard important for eco-friendly golf bag manufacturing?

The Materials Matter Standard is an internationally acknowledged certification that guarantees the raw materials used in manufacturing align with strict sustainability criteria. Its scope includes advancing climate objectives, safeguarding human rights, ensuring animal welfare, and conserving essential natural resources such as soil and water.

For golf bag manufacturers, this certification plays a key role in addressing the increasing consumer demand for environmentally conscious products. Following these standards not only helps create golf bags that are eco-friendly but also reinforces the brand’s commitment to sustainable practices, meeting both consumer expectations and industry benchmarks.