Golf bags made from recycled materials are reshaping how the industry handles waste and resources. They reduce plastic pollution, save energy, and contribute to a circular economy. However, challenges like durability concerns, higher costs, and design limitations make this shift complex. Manufacturers are addressing these issues through advanced materials, efficient production techniques, and collaborations with trusted suppliers.

Key insights:

- Materials: rPET (recycled polyester) repurposes billions of plastic bottles into durable fabrics. Recycled nylon from fishing nets also helps protect marine life.

- Energy Savings: Producing recycled polyester uses 59% less energy and cuts CO2 emissions by 32%.

- Challenges: Recycled materials may degrade faster, cost more, and face quality inconsistencies.

- Solutions: Companies use reinforced designs, hybrid fabrics, and localized sourcing to balance costs and performance.

Recycled golf bags are proving that eco-conscious designs can meet high standards while addressing waste and energy concerns.

Wilson Eco Golf Stand Bag – Made From Plastic Bottles – Review

Environmental Benefits of Using Recycled Materials

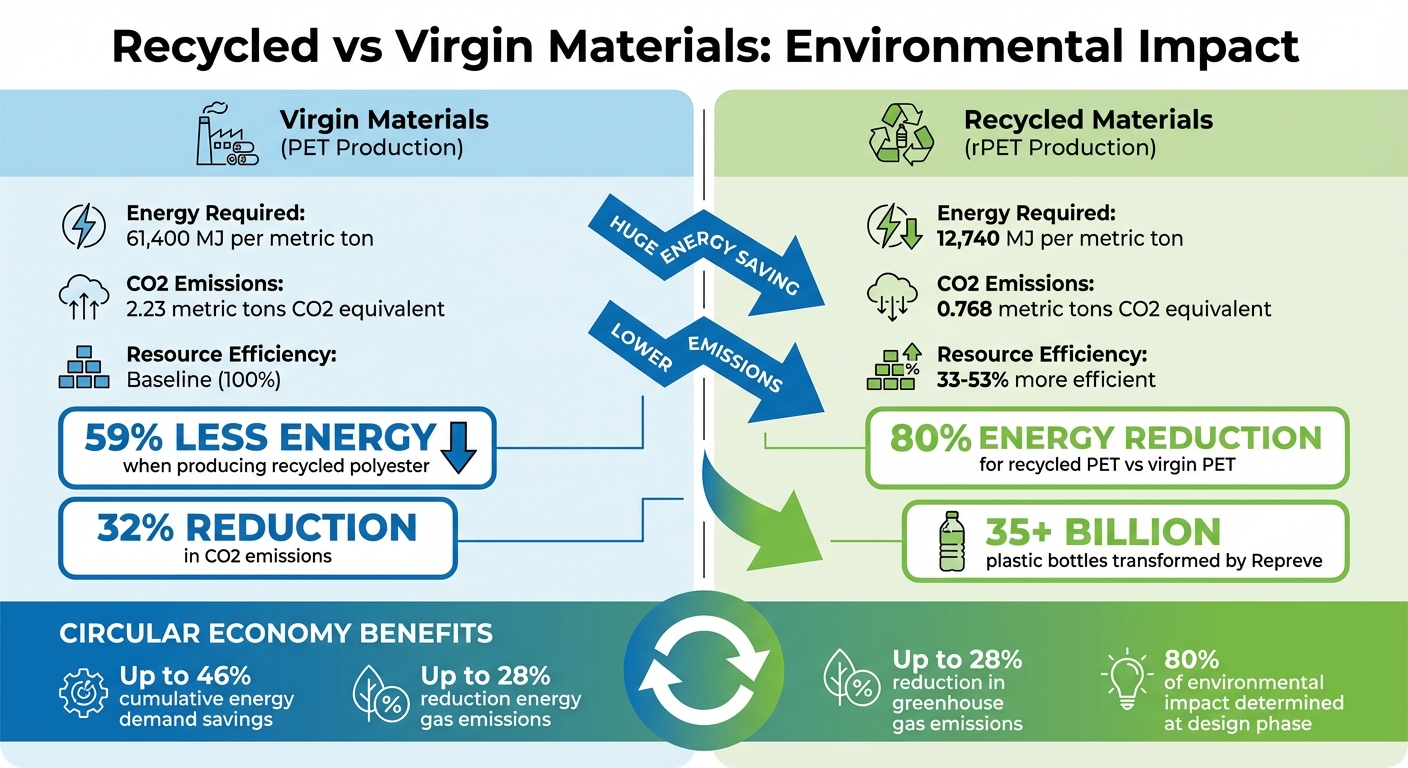

Environmental Impact: Recycled vs Virgin Materials in Golf Bag Production

Reduction in Plastic Waste

Using recycled materials plays a crucial role in cutting down on plastic waste. For example, when manufacturers opt for recycled polyester (rPET) to make golf bag fabrics, they’re giving a second life to post-consumer plastic water bottles that would otherwise linger in landfills for centuries. The scale of this effort is impressive – Repreve, a leader in recycled fiber production, has already transformed over 35 billion plastic water bottles into usable materials.

Recycled nylon is another game-changer. Programs like Seawastex collect abandoned fishing nets from the ocean and convert them into premium textile fibers. This initiative not only removes dangerous debris that threatens marine ecosystems but also repurposes the waste into high-performance materials, addressing two environmental challenges at once.

Energy and Resource Savings

Recycled materials aren’t just about waste reduction – they also save energy and resources. For instance, producing recycled polyester uses 59% less energy than creating virgin polyester and cuts CO2 emissions by approximately 32%. This shift marks a major step toward more resource-efficient manufacturing.

Take PET (the plastic found in water bottles) as an example. Virgin PET production requires 61,400 MJ of energy per metric ton, while recycled PET production needs only 12,740 MJ – an energy reduction of nearly 80%. Similarly, greenhouse gas emissions drop from 2.23 metric tons of CO2 equivalent for virgin PET to just 0.768 metric tons for recycled PET. This efficiency stems from skipping the energy-intensive process of extracting crude oil and natural gas. In fact, manufacturing rPET is 33%–53% more resource-efficient than its virgin counterpart. These energy savings align perfectly with efforts to build a more resource-conscious economy.

Supporting the Circular Economy

Recycled materials are reshaping how industries, including golf manufacturing, manage resources. Instead of the traditional "take-make-consume-throw away" model, manufacturers are now embracing a circular approach where materials are kept in use for as long as possible. This reduces reliance on finite raw materials and mitigates risks of supply chain disruptions.

The transformation starts during the design phase, where over 80% of a product’s environmental impact is determined. By designing products with resource recovery in mind, manufacturers can ensure materials are reused or recycled at the end of their life cycle. A well-designed circular plastics system has the potential to achieve up to 46% cumulative energy demand savings and reduce greenhouse gas emissions by up to 28%, compared to traditional linear systems. This approach turns waste into valuable raw materials, creating a cycle where yesterday’s plastic bottles become today’s golf bags – and those bags can eventually be recycled into something new. By integrating recycled materials, manufacturers not only promote sustainability but also introduce eco-friendly innovations for the golf industry.

Challenges in Adopting Recycled Materials

While using recycled materials can benefit the environment, it also introduces technical and financial hurdles that complicate the creation of sustainable golf bag designs.

Durability and Performance Concerns

One of the biggest challenges with recycled materials is maintaining durability. For instance, recycled natural fiber-reinforced polymer composites (NFRPCs) can only be reprocessed 4–6 times before their properties start to degrade. After seven cycles, their tensile strength drops by 17%, and tensile modulus decreases by 28%. This is a serious issue for golf bags, which need to endure rain, sun, and constant handling for 5–8 years. Such performance losses could significantly affect their longevity.

Weather resistance is another challenge. Recycling can change how materials absorb moisture, potentially making them less effective at protecting golf clubs from rain and humidity. Xianhui Zhao, a researcher at ORNL, explains:

"NFRPCs can generally be recycled approximately 4–6 times until their thermomechanical properties change".

Adding to the complexity, Professor Olga Troynikov from Sports Technology highlights:

"current recycling methods for composites are costly and yield low‐quality reusable materials".

This creates a tough situation for manufacturers trying to meet the high-performance standards golfers expect. These durability and performance issues not only increase costs but also place stricter demands on design.

Cost Implications

Recycled materials come with higher upfront costs. Research from Bain & Company shows that 65% of businesses identify these initial investments as a major barrier to adopting recycled materials. For example, Sun Mountain’s Eco-Lite stand bags, made with recycled materials, are priced at around $250, compared to their non-recycled C130 Cart Bag, which retails for $290.

However, the costs don’t end with the price tag. Early design decisions often lock in most of the environmental and financial burdens, forcing manufacturers to make difficult trade-offs. Additionally, Bain & Company found that 60% of manufacturing businesses struggle with limited access to recycled materials, which slows their adoption. Processing recycled advanced composites remains more expensive and technically challenging than working with virgin materials.

Design Limitations

Recycled materials also bring design challenges. Inconsistent quality in recycled feedstocks makes it harder to meet precise specifications. In fact, 60% of manufacturing leaders cite the limited availability of high-quality recycled materials as a major obstacle. For golf bags, this inconsistency complicates achieving features like UPF 40+ UV protection and incorporating 10–15% elastane for four-way stretch.

Meeting the high standards required for premium sports equipment often demands specialized partnerships and advanced sorting technologies. As a result, the design process becomes a balancing act, trying to align sustainability goals with the technical requirements needed for a reliable, high-performing golf bag.

sbb-itb-4fa7e8b

Solutions to Overcome Challenges

Manufacturers are finding practical ways to tackle the technical and financial challenges of using recycled materials in golf bags. These efforts focus on improving durability, managing costs, and refining designs. By combining advancements in materials, smarter production techniques, and strategic partnerships, they’re proving that eco-friendly products can still meet high-performance standards.

Advances in Material Technology

Recycled fabrics have come a long way and now often rival traditional materials in performance. For example, in 2022, Jones Sports Co. launched its R-series, using F35-R recycled ripstop fabric made entirely from single-use PET plastic bottles. To address concerns about durability, they reinforced high-stress areas with tension cross-stitching and reengineered the stand mechanism specifically for recycled textiles. As the company describes it:

"the most innovative, durable, and water-resistant fabric to date".

Another standout is Repreve polyester yarn, which has gained popularity for its strength and versatility. In August 2023, Sun Mountain introduced an updated Eco-Lite collection, partnering with Repreve to transform over 35 billion plastic bottles into performance fibers. These bags weigh about 4 pounds but maintain the durability of conventional models. Research also shows that recycled carbon fibers can retain more than 90% of their original mechanical strength when processed with advanced chemical recycling methods.

Hybrid materials are also making waves. Polycotton, a blend of organic cotton and recycled polyester, offers much greater strength for internal linings compared to 100% organic cotton. Fyfe Golf highlights this advantage:

"From testing and experience, the strength of polycotton is far greater than 100% organic cotton linings which is required to ensure durability and function for these products".

These innovations are paving the way for more efficient and cost-effective manufacturing.

Cost-Efficient Manufacturing Techniques

Manufacturers are finding ways to reduce the higher upfront costs of recycled materials through smarter production practices. For example, Callaway’s Chicopee facility upgraded its equipment to high-efficiency models, doubling production output while keeping energy consumption steady. A new chiller installation alone cut annual electricity use by 280 MWh.

Logistics also play a role. Redesigned packaging that nests golf bags more efficiently improves container utilization and lowers shipping costs. Some brands are even adopting dual-sourcing models, combining assembly in Southeast Asia with final customization closer to their markets. This approach helps them sidestep tariffs as high as 187.6% on golf bags imported from China.

Design innovations further help reduce long-term expenses. Features like magnetic pocket closures, which replace traditional zippers, lower repair and maintenance costs . Rovestar, for instance, sources 80% of its components from suppliers within 100 kilometers of its headquarters, cutting transportation costs while maintaining a 50% recycled material threshold.

Collaborations for Quality Assurance

Strategic partnerships are helping manufacturers ensure the quality of recycled materials. Sun Mountain’s collaboration with Repreve provides access to rigorously tested polyester yarn with proven UV resistance and tensile strength. Similarly, Seawastex works with responsible suppliers to source recycled nylon from recovered fishing nets, conducting extensive testing throughout the production process.

Global certification standards add another layer of quality assurance. Collaborating with suppliers that adhere to standards like the Responsible Wool Standard (RWS) or OEKO-TEX ensures materials meet strict safety and performance benchmarks. Minimal Golf emphasizes this commitment:

"We collaborate with responsible suppliers and participate in certified programmes which support a common goal for the environmental".

Some brands are also adopting take-back programs, creating a circular system where components can be reused, and non-recyclable parts are disposed of responsibly. These initiatives not only reduce waste but also improve material quality over time.

How Keep Perfect Golf Uses Recycled Materials

Keep Perfect Golf incorporates high-performance recycled fibers into its products, blending sustainability with functionality. For instance, it uses Repreve polyester, made from recycled plastic bottles, to deliver moisture-wicking, UV protection, and water resistance. Similarly, Seawastex nylon, sourced from recovered fishing nets, serves marine applications. These materials allow for designs that meet a variety of client demands.

Customization with Recycled Materials

Clients can opt for recycled materials when designing custom golf bags. Advanced dyeing techniques provide an extensive range of color choices, while polycotton blends offer enhanced durability compared to 100% organic cotton. This approach not only meets individual preferences but also aligns with Keep Perfect Golf’s commitment to eco-conscious manufacturing.

Sustainability in OEM/ODM Services

Sustainability is a cornerstone of Keep Perfect Golf’s OEM/ODM services. From initial design to final delivery, the company integrates eco-friendly practices at every stage. Products undergo stringent testing to ensure they meet standards for tensile strength, water resistance, and UV protection. Additionally, direct factory production helps reduce costs without compromising quality.

Client Success Stories

Thanks to these sustainable innovations, both corporate and retail clients have embraced Keep Perfect Golf’s eco-friendly, custom golf bags. Their success highlights that environmental responsibility and high performance can go hand in hand.

Conclusion: Balancing Benefits and Challenges

The move toward using recycled materials in golf bag production offers clear environmental advantages. However, navigating this shift involves addressing key trade-offs. Challenges like durability concerns and cost pressures remain, but these can be tackled through thoughtful material choices during the design process – when around 80% of a product’s environmental impact is determined.

Manufacturers are finding success by combining recycled materials with synthetic ones, strategically adding synthetics where extra durability is essential. They also prioritize rigorous testing and source materials locally to help manage costs. These approaches tie back to earlier discussions on overcoming technical and financial hurdles.

"We believe performance and sustainability can co-exist." – Minimal Golf

Illustrating this philosophy, Keep Perfect Golf incorporates Repreve polyester and Seawastex nylon into their eco-friendly designs, showing that sustainability doesn’t have to come at the expense of performance. Their OEM/ODM services focus on integrating environmentally conscious practices at every stage while maintaining high standards for tensile strength, water resistance, and UV protection.

The future of the golf industry hinges on prioritizing sustainability in design. With golf bags having a relatively short lifespan, the responsibility extends beyond material choices to include solutions for the end of their lifecycle. Companies that embrace this approach position themselves as leaders committed to both high performance and environmental responsibility.

FAQs

What are the benefits of using recycled materials in designing golf bags?

Using recycled materials in golf bag design brings multiple advantages. For starters, it helps cut down plastic waste and decreases greenhouse gas emissions, playing a part in creating a cleaner planet. Plus, these materials can be transformed into golf bags that are not only lightweight, durable, and water-resistant but also retain key features like moisture-wicking and UV protection.

Opting for golf bags made from recycled materials allows golfers to enjoy top-tier performance while backing environmentally conscious practices.

How do manufacturers ensure recycled materials are durable enough for golf bags?

Manufacturers are tackling durability concerns by creating recycled materials that can hold their own against traditional options like nylon or polyester. Take fabrics made from recycled plastic bottles, for example – they’re designed to resist tearing, abrasion, and general wear while staying lightweight. Some golf bags even incorporate these recycled plastic blends, reinforcing them with double-stitched seams and sturdy structural elements to withstand the rigors of daily use.

To ensure these materials meet the high standards golfers expect, manufacturers put them through rigorous testing and fine-tune their designs. By blending recycled polymers, reinforced stitching, and smart engineering, they’re crafting eco-friendly golf bags that deliver on both durability and environmental responsibility. It’s proof that recycled materials can rise to the challenge without sacrificing performance.

Why are golf bags made with recycled materials often more expensive?

Golf bags made from recycled materials often carry a higher price tag, and here’s why. Turning post-consumer waste, like plastic bottles, into durable, high-quality fabric involves extra steps. The process includes collecting, cleaning, and processing these materials, which can be more labor-intensive and expensive than working with traditional materials.

On top of that, these recycled fabrics are typically produced in smaller quantities, driving up production costs. The rising demand for sustainable products also impacts pricing, as manufacturers invest in eco-conscious innovations that prioritize reducing waste over cutting costs. While these bags may cost more, they play a part in minimizing waste and supporting sustainability within the golf industry.