When selecting a golf bag manufacturer for custom OEM orders, focus on these key areas to ensure quality, reliability, and alignment with your business needs:

- Quality Standards:

- Check for durable materials, rigorous testing (e.g., stress tests, water resistance), and certifications like ISO 9001.

- Review defect management policies and request detailed quality reports.

- Production and Customization:

- Ensure the manufacturer can handle your order volume and customization needs (e.g., logo embroidery, color-matching).

- Assess their ability to deliver prototypes quickly and refine designs efficiently.

- Reputation and Client Feedback:

- Look for manufacturers with a strong track record and diverse client portfolios.

- Verify testimonials, case studies, and references to gauge reliability and communication.

- Facility and Equipment:

- Inspect their production setup, equipment condition, and quality control processes.

- Ensure raw materials and finished goods are stored properly.

- Communication and Transparency:

- Evaluate response times, clarity, and pricing transparency.

- Ask about project tracking systems and support for urgent issues.

- Lead Times and Costs:

- Plan for sampling and production timelines, considering shipping and customs clearance.

- Understand cost structures, including customization fees and potential savings for larger orders.

- After-Sales Support:

- Look for warranties covering defects and clear return/exchange policies.

For a trusted partner, consider manufacturers like Keep Perfect Golf Gear, known for their extensive experience, customization options, and direct factory production with transparent pricing.

How Golf Bags Are Made? 🏅 Inside a Professional Golf Bag Factory Tour

Key Criteria for Evaluating a Golf Bag Manufacturer

Choosing the right OEM golf bag manufacturer is a critical step that can directly influence the quality and success of your product. To make an informed decision, it’s important to focus on factors like quality standards, production capabilities, and the manufacturer’s reputation.

Quality Control Standards

The durability and performance of a golf bag start with the materials. Manufacturers that use high-grade materials designed for durability – such as those with strong tear resistance and weatherproofing – are better equipped to produce reliable products. Pay attention to whether the manufacturer performs rigorous testing, such as stress tests on zippers, durability checks for pockets, and water resistance evaluations. Ask for documentation that details these tests and their results.

Consistency in production is equally important, especially for large-scale orders. Manufacturers adhering to recognized quality management systems, like ISO 9001, often have structured quality control processes in place. These systems ensure that every step, from cutting materials to final packaging, meets your specifications.

Also, review their defect management and warranty policies. Detailed quality reports for each production batch can provide insights into their manufacturing reliability and transparency.

Production and Customization Capabilities

Assess the manufacturer’s production capacity to ensure they can meet your volume requirements, including handling rush orders when needed. Modern equipment, such as computer-controlled cutters and programmable embroidery machines, plays a crucial role in delivering precise and consistent results. Don’t hesitate to inquire about the age and maintenance of their machinery to avoid potential inconsistencies.

Customization is another key area. Some manufacturers may only offer basic options like logo embroidery, while others can handle more intricate designs. Request detailed information about their customization processes, including minimum order requirements, color-matching capabilities, and timelines for developing prototypes.

Quick sample development is a strong indicator of operational efficiency. A manufacturer that can produce initial samples promptly and address revisions quickly is more likely to stay aligned with your product launch schedule. Delays in this process may point to resource or process limitations.

Reputation and Client Portfolio

A manufacturer’s reputation speaks volumes about their reliability. Those with extensive experience in golf bag production are often better equipped to manage seasonal demand, anticipate material performance issues, and navigate design challenges. A diverse client portfolio, including both small retailers and large enterprises, suggests they can handle a variety of order sizes and requirements.

Certifications for ethical manufacturing and textile safety are also important, particularly if you operate in regulated markets or work with clients who demand strict compliance. These credentials reflect professionalism and a commitment to industry standards.

Financial stability is another critical factor. Investigate the manufacturer’s business history, including facility ownership and client retention rates. Signs of financial instability could lead to disruptions in your supply chain.

Finally, effective communication can make or break a partnership. Evaluate how quickly and clearly the manufacturer responds to inquiries, their fluency in English, and their availability across time zones. Manufacturers who assign dedicated account managers and provide regular updates throughout the production process often ensure smoother collaboration and fewer misunderstandings.

How to Assess Potential Manufacturers

When you’re searching for the right manufacturer, it’s crucial to evaluate their ability to meet your specific needs. This involves reviewing product samples, client feedback, facilities, and communication practices. Here’s how you can approach this process.

Request and Evaluate Product Samples

Samples are your first glimpse into a manufacturer’s ability to meet your standards. Always request samples tailored to your specifications rather than generic items from their catalog. This gives you a clearer picture of their custom capabilities.

When inspecting samples, pay close attention to construction quality. For example, check stress points like zippers, pocket stitching, and strap connections – these areas often wear out first in products like golf bags. Test zippers repeatedly to ensure smooth operation and durability. If the product includes embroidery or printed logos, examine the thread tension and color consistency for a polished finish.

Don’t just look – feel the materials too. Assess fabric weight and texture to judge durability. Check for consistent color matching across all fabrics, and if the product is supposed to be water-resistant, ensure the coating feels smooth and evenly applied. Sticky or rough patches can signal poor craftsmanship.

Document any flaws you find and share your feedback with the manufacturer. Their response will tell you a lot about how they handle quality control and revisions. A professional manufacturer will welcome your input and provide a clear timeline for addressing any issues.

Once you’ve reviewed samples, it’s time to dig into what other clients have experienced.

Review Client Testimonials and Case Studies

Client testimonials can shed light on aspects that marketing materials often gloss over. Look for specific feedback about delivery times, quality consistency, and how the manufacturer handles challenges. Testimonials from companies with similar order sizes and customization needs to yours are particularly helpful.

Case studies go a step further by offering detailed examples of how the manufacturer has solved problems in the past. For instance, how did they manage a last-minute design change or a material shortage? These examples can reveal their problem-solving skills and ability to adapt under pressure.

Don’t stop at written testimonials – verify references directly. Ask detailed questions about communication, delivery schedules, and how the manufacturer handled any production hiccups. Long-term clients are especially valuable sources of insight into reliability over time.

For a broader perspective, check social media and industry forums. Search for mentions of the manufacturer alongside terms like "delays" or "quality issues" to identify any recurring problems.

Next, take a closer look at their facilities to ensure they have the operational capacity to meet your needs.

Inspect Manufacturing Facilities

Visiting a manufacturer’s facility, whether in person or virtually, gives you the clearest sense of their capabilities. Focus on their production flow, equipment condition, and overall organization. A tidy, well-organized facility with clearly marked quality control stations is often a sign of consistent output.

Start by observing the cutting and pattern-making areas, as precision here impacts the entire production process. Modern facilities often use computer-controlled cutting systems for accuracy, while manual operations require skilled workers to maintain consistency across large orders.

Check the condition of sewing machines and embroidery equipment. Well-maintained machines are essential for high-quality production. Ask about their maintenance schedules and whether they have backup equipment to avoid delays caused by breakdowns.

Quality control should be integrated throughout the production line – not just at the final stage. Look for documented inspection procedures and systems for tracking quality issues.

Storage areas also reveal a lot about a manufacturer’s organization. Raw materials should be stored in climate-controlled conditions to prevent damage, while finished goods should be handled carefully to avoid issues before shipping.

Check Communication and Transparency

Strong communication is the backbone of a successful partnership. Assess how quickly they respond to your inquiries and how thoroughly they answer your questions. Detailed, technical responses often indicate a higher level of expertise.

Language proficiency is key. Test their ability to communicate effectively through emails, phone calls, and video conferences. Misunderstandings early on can escalate into costly mistakes later.

Transparency is equally important. Ask for a detailed breakdown of costs, including tooling fees, setup charges, and any surcharges for rush orders or design changes. Manufacturers who are upfront about pricing are more likely to maintain open, honest communication throughout your partnership.

For complex orders, project management becomes critical. Ask about their tracking systems and how they report progress. Reliable manufacturers should provide regular updates on production, material sourcing, and any potential delays. They should also keep thorough documentation of all design specifications and approved changes.

Finally, consider time zone differences. Efficient communication during urgent situations requires clear protocols. Some manufacturers assign account managers who work extended hours for international clients, while others stick to standard business hours, which could slow down problem resolution. Make sure their approach aligns with your needs.

Customization and Branding Requirements

Once you’ve evaluated the quality and production capabilities, it’s time to think about how well a manufacturer can tailor their products to fit your brand. A custom golf bag should not only showcase your brand’s identity but also provide practical features that enhance usability. Look for manufacturers that offer a range of customization options, including ergonomic straps for comfort, waterproof materials for durability, well-thought-out pocket layouts for convenience, and advanced club organization systems to keep everything in place.

sbb-itb-4fa7e8b

Lead Times, Costs, and Support Services

Once you’ve established quality and customization as priorities, it’s time to focus on the practical aspects: production timelines, costs, and ongoing support. These factors are crucial to ensuring a seamless partnership with your chosen manufacturer.

Comparing Production Lead Times

Production timelines can greatly influence your planning and inventory management. Manufacturers generally operate in two stages: sampling and full production. The sampling phase ensures that materials, stitching, and customizations meet your expectations before moving into full production. The duration of the full production phase depends on the complexity of your order and the customizations involved.

Shipping methods also play a big role in delivery schedules. Air freight is faster but comes at a higher cost, while sea freight offers savings with longer transit times. Customs clearance, especially during busy periods, can introduce additional delays. Considering these factors will help you set realistic timelines and avoid unexpected hiccups.

Understanding Cost Structures

Costs can vary widely depending on several factors, including unit pricing, customization fees, shipping methods, and minimum order quantities. Generally, the more you order, the lower the unit cost. However, opting for premium materials or intricate customizations can increase expenses.

Some manufacturers offer incentives, such as waiving setup fees for larger orders or providing free shipping once you hit a certain spending threshold. Understanding these cost structures allows you to budget effectively and potentially save on larger orders.

After-Sales Support and Warranty

A manufacturer’s after-sales support speaks volumes about their professionalism. Look for companies that back their products with warranties covering manufacturing defects like zipper malfunctions, strap issues, or material flaws under normal use. These warranties often include replacements or refunds for items that fail to meet agreed specifications.

Pre-shipment inspections, while adding some extra time, are a good way to confirm product quality before shipping. Communication is key during this phase – manufacturers offering dedicated support and real-time updates make it easier to address any concerns and stay informed about your order’s progress.

Finally, make sure return and exchange policies are clearly outlined. Knowing how defects or quality issues will be handled can save you from potential disputes and provide confidence in your partnership. By evaluating these logistical and cost considerations, you’ll be better prepared to make an informed decision.

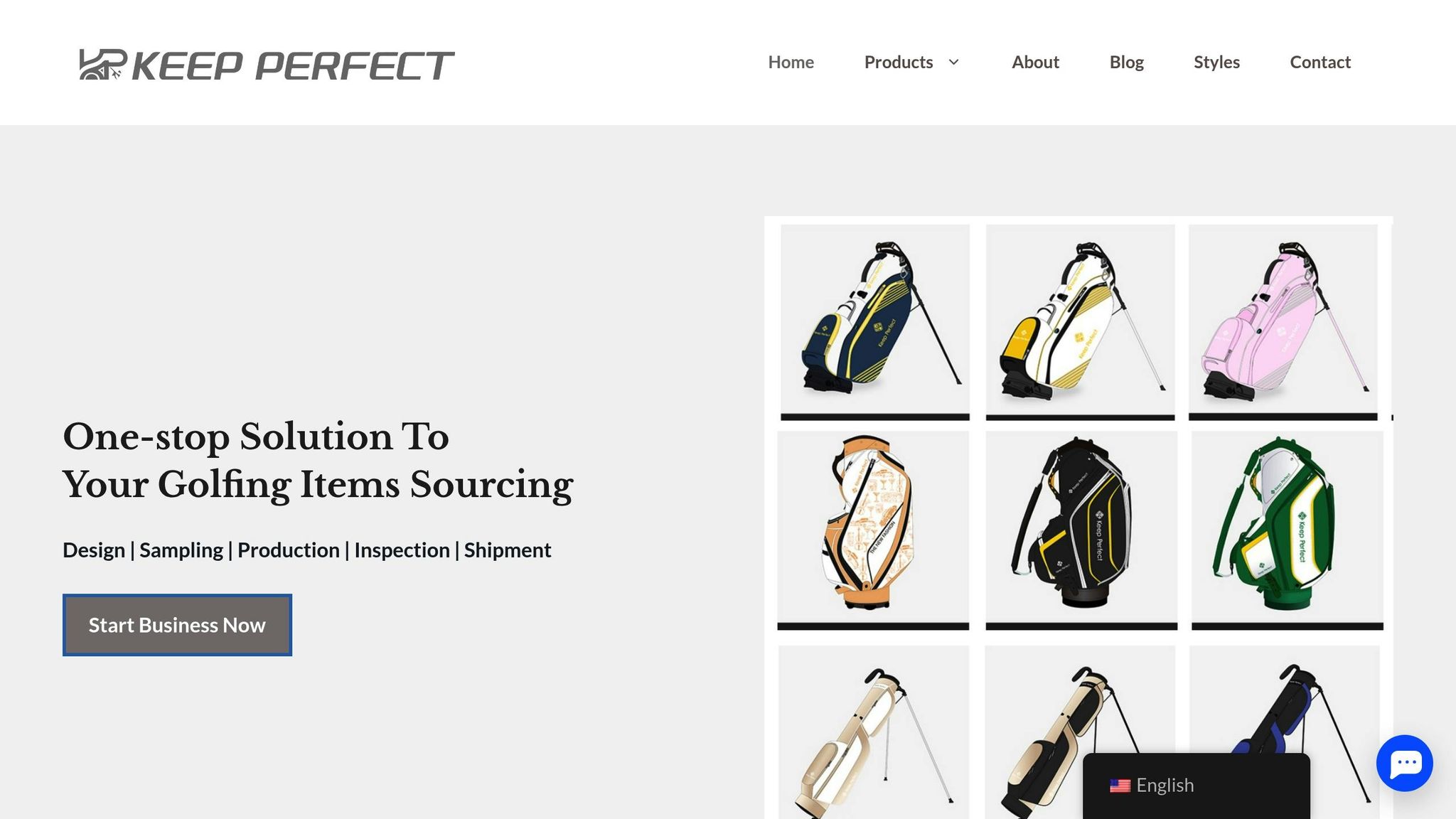

Why Choose Keep Perfect Golf Gear for OEM Orders

Keep Perfect Golf Gear has earned its reputation as a trusted custom OEM partner, backed by over ten years of experience and a client base spanning more than 100 global businesses. Here’s what makes them a standout choice.

All-in-One OEM/ODM Solutions

Keep Perfect Golf Gear simplifies the production process by offering a comprehensive solution from start to finish. They take care of everything – from turning your initial ideas into fully developed products to managing factory production, ensuring cost efficiency, and handling worldwide delivery. They even provide warehousing and storage options. By managing the entire process under one roof, they save you the trouble of juggling multiple vendors, making project management smooth and hassle-free.

Extensive Customization Options

Customization is where Keep Perfect Golf Gear truly shines. They go beyond simply adding logos, allowing clients to choose from a variety of options, including materials, patterns, and designs. Whether you need custom golf cart bags, lightweight stand bags, or compact Sunday bags, you can tailor every detail – from color schemes and hardware finishes to pocket configurations – to match your vision.

Dependable Service and Transparent Pricing

With direct factory production, Keep Perfect Golf Gear eliminates intermediaries, keeping costs manageable and predictable. Their rigorous quality warranty ensures every product meets top-tier industry standards, offering peace of mind for both retailers and end users. Plus, their clear pricing structure breaks down costs for materials, customization, and shipping, making it easier for U.S. businesses to budget accurately. Reliable delivery schedules also help align inventory planning with marketing launches, ensuring everything runs smoothly.

Conclusion

Key Takeaways

Finding the right OEM golf bag manufacturer is all about careful evaluation. Start by assessing their quality standards – look for established inspection processes and certifications that guarantee consistent results. Make sure they have the production capacity to handle your order volume and offer the customization options you need to stand out.

Equally important is clear and open communication. A reliable manufacturer should respond quickly, provide clear timelines, and maintain transparency throughout the production process. This kind of partnership can help you avoid unnecessary delays and unexpected costs. Don’t forget to factor in lead times and ensure pricing structures are straightforward to align with your market goals.

Lastly, take the time to evaluate samples thoroughly. Request modifications if needed and test how well the manufacturer incorporates your feedback. This process not only helps avoid costly errors but also gives you a clear picture of their ability to meet your expectations.

Final Thoughts

Ultimately, the success of your custom OEM orders hinges on choosing a partner who can bring your vision to life. Golf bags need to strike the perfect balance between durability and style, making your choice of manufacturer a key business decision.

Keep Perfect Golf Gear stands out by offering comprehensive OEM solutions with extensive customization options and transparent pricing. Their one-stop approach simplifies the production process, ensuring consistent quality without the hassle of juggling multiple vendors.

Look for partners who offer competitive pricing without compromising on quality. The right manufacturer will not only meet your current needs but also position your brand for growth as you carve out a larger share of the competitive golf accessories market.

FAQs

What certifications should a golf bag manufacturer have to guarantee top-notch quality?

When deciding on a golf bag manufacturer, it’s important to check for certifications that highlight their dedication to quality, ethical practices, and environmentally conscious production. Key certifications to look for include ISO 9001, which ensures strong quality management systems, BSCI, reflecting a commitment to social responsibility, and GRS (Global Recycled Standard), which verifies the use of recycled and eco-friendly materials. Manufacturers adhering to standards like ASTM D6400 or EN 13432 demonstrate their use of sustainable practices. These certifications are strong indicators of a dependable manufacturer that meets rigorous quality expectations.

How can I check a golf bag manufacturer’s reputation and customer feedback before placing an order?

To get a clear picture of a manufacturer’s reputation and customer feedback, start by diving into their client testimonials and case studies. Pay attention to recurring patterns in customer experiences – these can highlight both strengths and any potential issues. For a hands-on evaluation, ask for sample products to personally assess their quality.

Expand your research by exploring social media mentions, industry-specific review platforms, and online forums for more impartial insights. If you can, connect directly with past clients to hear about their experiences firsthand. Taking this thorough approach will give you the confidence to make a well-informed choice and build a trustworthy partnership.

What should I look for in a manufacturer’s production and customization capabilities for custom OEM golf bags?

When selecting a manufacturer for custom OEM golf bags, it’s essential to prioritize their experience and dependability in delivering top-tier products. Look into their track record for managing your desired order volume, adhering to deadlines, and maintaining consistent quality through effective control measures. Requesting samples or prototypes can provide valuable insight into the quality of their work.

For customization, check their ability to offer varied design options, material selections, and branding features. A dependable manufacturer should be equipped to produce personalized products that reflect your unique requirements, ensuring your design vision and quality standards are upheld. Open and clear communication, along with a history of successful custom projects, is key to building a strong and productive partnership.