China is a global leader in custom golf bag manufacturing, offering high-quality products with competitive pricing. Many factories specialize in OEM/ODM services, managing everything from design to delivery. For U.S. buyers, these manufacturers provide reliable solutions that meet international quality standards, often backed by certifications like ISO. Here’s a quick rundown of the top 10 factories excelling in custom golf bag production, focusing on their capabilities, quality control, and export reliability:

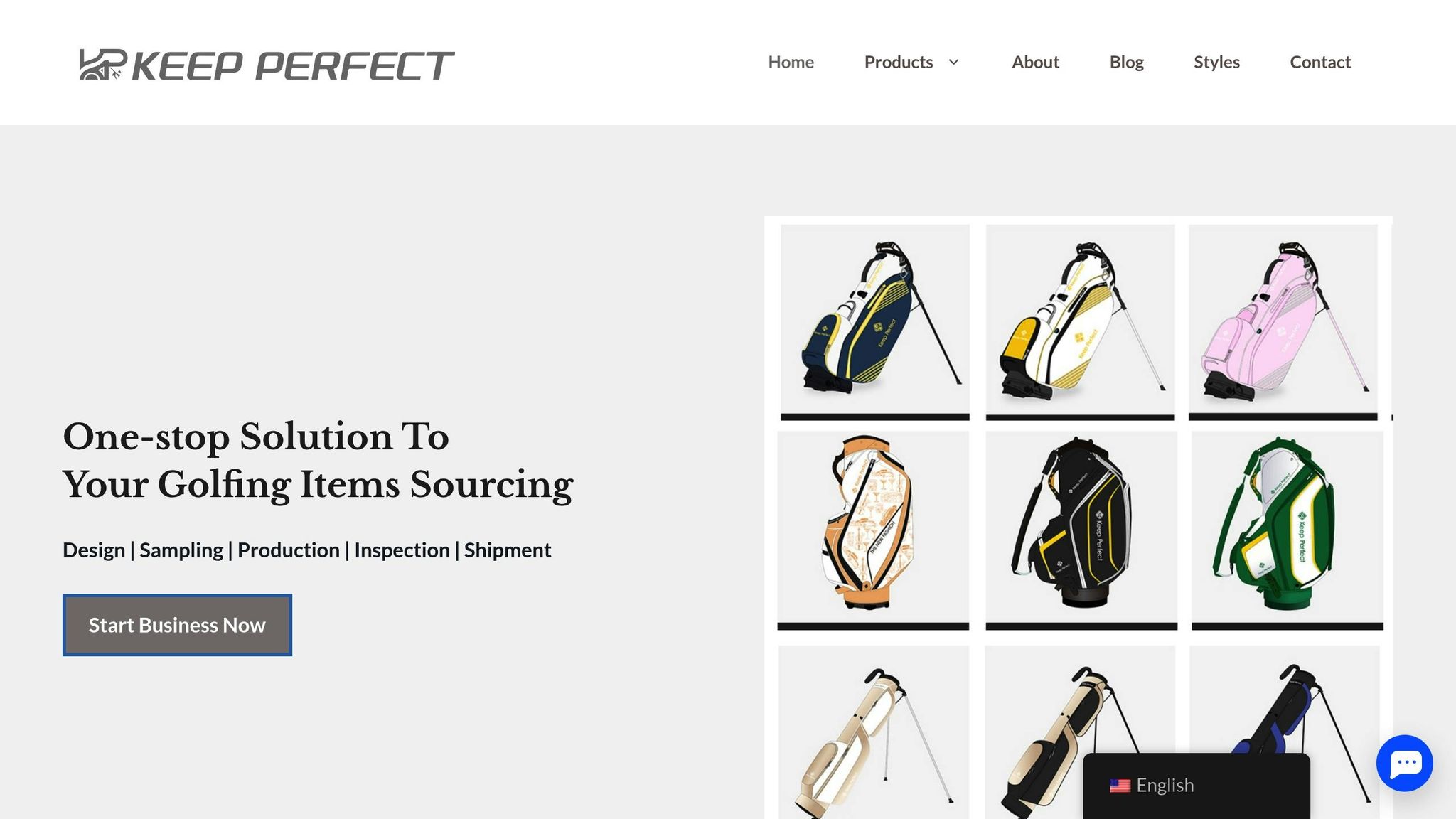

- Keep Perfect Golf Gear: Known for end-to-end custom solutions and fast lead times.

- Yiyang Golf Products Co., Ltd.: Specializes in waterproof golf bags with advanced technology.

- Xiamen MLG Sports Equipment Co., Ltd.: Offers strict quality assurance verified by TüVRheinland.

- Dongguan Yisuoti Sports Goods Co., Ltd.: High production capacity with efficient turnaround times.

- LEGEND TIMES Co., Ltd.: Experts in premium leather golf bags and branding options.

- Dongguan Gostar Sporting Goods Co., Ltd.: Strong design team with a focus on customization.

- Xiamen Justin Imp. & Exp. Co., Ltd.: Offers extensive R&D and quick prototyping.

- Dongguan Changrong Sporting Goods Co., Ltd.: ISO-certified with a focus on quality-first manufacturing.

- Shenzhen Yihui Industrial Co., Ltd.: Provides private mold tooling and fast sample production.

- Dongguan Hotsun Sporting Goods Co., Ltd.: Reliable OEM/ODM services with custom branding options.

These manufacturers cater to different needs, from small custom orders to large-scale production. Whether you’re looking for waterproof designs, premium leather options, or fast delivery, this list highlights the best options for sourcing golf bags in China.

How Golf Bags Are Made? 🏅 Inside a Professional Golf Bag Factory Tour

1. Keep Perfect Golf Gear

Keep Perfect Golf Gear specializes in creating custom golf bags, handling everything from design to delivery. Founded by Marvin, the company has built a reputation for its top-tier craftsmanship and personalized service, catering to international clients, with a strong focus on U.S. customers looking for tailored golf equipment.

OEM/ODM Capabilities

Their OEM/ODM services cover every aspect of customization. From design consultations to logo personalization – using printing or embroidery techniques – they offer a wide range of material options, including premium leather and durable synthetics. This allows them to produce a variety of custom bags, such as cart bags, stand bags, and Sunday bags.

The company oversees the entire production process, ensuring consistency and maintaining strict quality standards at every step.

Quality Certifications and Control Processes

Quality is a cornerstone of Keep Perfect Golf Gear’s operations. Each golf bag undergoes meticulous inspections to ensure material durability, precise stitching, functional hardware, and overall construction excellence before it’s packaged for delivery.

Customer testimonials reflect their dedication to quality. Ricky Tetting, a U.S. customer, shared:

"WOW!!! Thank you for this amazing customization. I love my logo golf bags. They are perfect! I highly recommend them, for the fastest shipping, the most professional service, and bags. I will return again and again."

Similarly, Remini from Germany praised their work:

"Thanks to Keep Perfect Golf, we created our team’s golf bag designs, and they are of amazing quality. We like them."

Production Capacity and Lead Times

Keep Perfect Golf Gear is well-equipped to handle custom orders efficiently. Their manufacturing facility includes warehousing and storage solutions, allowing them to manage inventory for repeat clients and fulfill larger orders seamlessly. Thanks to their streamlined processes, they can maintain competitive lead times, a point often highlighted by customers who commend their "fastest shipping" services.

Export Markets and Reputation for Reliability

The company has built strong relationships with clients across the globe, including markets in the United States, Germany, and Korea. Their ability to meet diverse market needs and shipping demands underscores their reliability.

Sehun King from Korea shared his positive experience:

"Looks great, they are well-designed and well-made. We will place another order again."

The high rate of repeat business speaks to the trust and satisfaction customers have in Keep Perfect Golf Gear’s capabilities. With a reliable international delivery network, U.S. customers can count on timely shipments, making the company a dependable choice for both businesses and individuals looking for custom golf bags manufactured overseas.

2. Yiyang Golf Products Co., Ltd.

Yiyang Golf Products Co., Ltd. stands out as a dedicated manufacturer of waterproof golf bags, backed by a well-established production facility. Spanning roughly 10,000 square meters (107,639 square feet), their factory is designed to support high-quality manufacturing and advanced OEM services.

OEM/ODM Capabilities

Yiyang’s production lines are equipped with specialized machinery that allows them to offer tailored OEM services. Their expertise includes incorporating advanced waterproofing technologies and custom design features to meet specific client needs.

Quality Certifications and Control Processes

Quality is a top priority for Yiyang. The company conducts thorough testing to ensure every product meets high standards. These tests cover waterproofing effectiveness, zipper performance, fabric durability, color retention, and tensile strength.

Production Capacity and Lead Times

With 8 production lines and a workforce of 300 employees, Yiyang produces up to 20,000 golf bags each month. This capacity ensures they can handle large-scale orders while maintaining a lead time of 60 days post-order confirmation. This timeline balances meticulous quality checks with international shipping requirements.

Export Markets and Reputation for Reliability

Yiyang’s focus on waterproof technology and strict quality standards has earned them a strong reputation globally. Their consistent production capabilities and reliability have fostered long-term partnerships with OEM clients seeking high-quality waterproof golf bags.

3. Xiamen MLG Sports Equipment Co., Ltd.

Xiamen MLG Sports Equipment Co., Ltd. has earned a strong reputation in the industry by meeting rigorous quality standards. The company has achieved Audited Supplier status, verified by TüVRheinland, which underscores its commitment to maintaining international manufacturing benchmarks.

Quality Certifications and Control Processes

At the core of Xiamen MLG’s operations is a robust quality assurance framework. Independent assessments by TüVRheinland confirm that the company adheres to strict operational standards. Additionally, its detailed raw material identification and traceability systems ensure that every component is meticulously accounted for throughout the production process.

Export Markets and Reputation for Reliability

These quality measures translate into a stellar market reputation. The company boasts a 4.9/5 rating from 665 verified reviews, reflecting high customer satisfaction. One customer shared their experience, saying, "Fantastic company, great quality, and timely delivery as always. Always great to work with!". Moreover, Xiamen MLG’s strong after-sales support further solidifies its standing as a reliable partner in the global market.

4. Dongguan Yisuoti Sports Goods Co., Ltd.

Dongguan Yisuoti Sports Goods Co., Ltd. stands out for its impressive production capabilities and efficient turnaround times. Specializing in custom golf bag manufacturing, the company operates a dedicated facility designed to meet the needs of businesses looking for dependable and tailored golf bag solutions. Its emphasis on production capacity and streamlined processes makes it a strong contender in the custom golf bag market.

Production Capacity and Lead Times

Operating out of a 24,000-square-foot facility, the company runs 2 production lines equipped with 58 machines, enabling it to manufacture up to 100,000 golf bags annually. For custom orders, production takes 25 days, with an additional 10 days for transportation, resulting in a total lead time of about 35 days.

Here’s a breakdown of lead times based on order size:

- 1–100 pieces: Fixed lead time of 40 days.

- More than 100 pieces: Lead times are negotiable, with custom arrangements available.

This level of efficiency highlights the company’s ability to meet global demand without compromising on quality.

Workforce and Operational Consistency

The company’s 39-member team ensures steady production output and operational reliability. This skilled workforce plays a key role in maintaining the company’s reputation for delivering consistent results.

5. LEGEND TIMES Co., Ltd.

LEGEND TIMES Co., Ltd. stands out as a leader in the OEM/ODM custom golf bag industry. Operating from a 53,820-square-foot facility, they combine traditional craftsmanship with cutting-edge technology to create high-quality golf bags and headcovers. This commitment to precision and quality underscores China’s reputation as a hub for custom golf bag manufacturing.

OEM/ODM Capabilities

LEGEND TIMES offers comprehensive custom golf bag production services. Their OEM capabilities provide clients with tailored designs and access to premium materials, ensuring each product meets unique specifications.

The company is particularly known for its premium leather golf bags, which allow for extensive customization. Joyce Ho, Founder of LEGEND TIMES Co., Ltd., highlights the importance of branding in their approach:

"Offering premium leather golf bags with custom branding options helps position your brand as exclusive and customer-centric. Custom logos, color schemes, and unique design features can make each bag a distinct representation of your brand’s identity."

Their material selection focuses on combining durability with style, offering a range of high-quality options that can be customized to align with specific branding and performance needs.

Quality Certifications and Control Processes

LEGEND TIMES upholds strict quality standards through certified testing and compliance. They hold an SGS Certificate for Raw Material (PU) Testing and ensure all materials meet CA65 and REACH181 standards.

Their quality control system is backed by advanced testing equipment and follows a meticulous workflow. Every stage of production – designing, cutting, stitching, punching, finishing, packing, and final quality checks – is carried out with precision.

Production Capacity and Lead Times

With a workforce of over 200 employees, LEGEND TIMES has the resources to maintain impressive production levels. Their facility is equipped with 2 cutting machines and 75 sewing machines, enabling them to produce up to 40,000 golf bags annually, including 5,000 premium models. This contributes to an annual sales turnover of $9.5 million.

Custom orders typically take 4-6 weeks, depending on complexity, with a standard minimum order quantity of 100 units (adjustable for specific needs). For their PU Golf Tour Club Bag model (CB-070), they offer a 2-week sample lead time and complete orders within 30-45 days after confirmation.

| Production Metric | Specification |

|---|---|

| Annual Capacity | 40,000 golf bags |

| Monthly Capacity | 8,000 pieces |

| Custom Order Lead Time | 4-6 weeks |

| Sample Lead Time | 2 weeks |

| Minimum Order Quantity | 100 pieces (adjustable) |

6. Dongguan Gostar Sporting Goods Co., Ltd.

Since its founding in 1998, Dongguan Gostar Sporting Goods Co., Ltd. has built a reputation for crafting custom golf bags and offering comprehensive OEM and ODM services.

OEM/ODM Capabilities

Gostar stands out for its strong design capabilities, supported by an independent development team with over 20 designers. These experts work swiftly to turn customer concepts into tangible products, ensuring designs align with changing market trends.

Customization is where Gostar truly shines. The company provides options for golf bags that vary in type, size, and pocket configurations, catering to a wide range of branding needs. Clients can also tailor the color schemes of their bags across all product lines, giving them full control over their brand’s visual identity.

When it comes to materials, Gostar offers durable choices like waterproof nylon and PU leather. For branding, the company provides several options, including logo printing and embroidery techniques, allowing for a polished and professional finish.

The minimum order quantity (MOQ) for most custom golf bag products is 100 pieces. This includes popular designs like the Premium PU Golf Stand Bag with customized logos and colors, the Outdoor Sports Golf Bag with tailored embroidery, and the Customizable Golf Caddy Bag with personalized logo options. These services are backed by rigorous quality control measures to ensure client satisfaction.

Quality Certifications and Control Processes

Gostar places a high priority on quality assurance, demonstrated by its adherence to strict certification processes. In 2025, the company was verified onsite by TüVRheinland, a globally recognized inspection organization, as part of Alibaba.com’s Supplier Assessments program. This certification confirms the company’s operational and manufacturing standards.

Additionally, Gostar operates as an Audited Supplier on Made-in-China.com, with all business licenses verified. Its quality control process includes thorough inspections of raw materials to ensure that only top-quality components are used in production.

The manufacturing process combines premium materials with advanced equipment, ensuring every product meets high standards. Independent workshops staffed by skilled designers and technicians oversee production, maintaining strict quality control at every step. This approach ensures efficient workflows and reliable results.

Production Capacity and Lead Times

Gostar’s production facilities are designed to support its extensive OEM and ODM services. With independent workshops and specialized tools, the company ensures efficient workflows. A team of over 20 designers collaborates with experienced technicians to deliver high-quality products on time.

The company’s flexibility is evident in its ability to handle diverse order sizes. Whether it’s a small custom order or a larger production run exceeding 100 pieces, Gostar has the infrastructure to meet varying demands. This scalability makes it a dependable partner for both niche boutique brands and larger distributors in the golf equipment market.

sbb-itb-4fa7e8b

7. Xiamen Justin Imp. & Exp. Co., Ltd.

With 30 years of experience in the golf industry, Xiamen Justin has established itself as a go-to provider for OEM/ODM solutions. Like other top manufacturers in this review, the company blends forward-thinking design with a commitment to quality, making it a standout among custom golf bag factories in China.

OEM/ODM Capabilities

Xiamen Justin’s expertise lies in its all-encompassing approach to custom golf bag production. Their dedicated R&D team, consisting of seven members, is consistently at work, rolling out new designs and products every month.

Customization options are extensive. Clients can choose from flexible designs, a variety of materials like nylon, PU leather, and polyester, and personalized logo printing. Whether it’s minor tweaks to existing designs or fully custom creations based on detailed drawings, Xiamen Justin delivers. Their ability to adapt production strategies while maintaining rigorous quality standards sets them apart.

Quality Certifications and Control Processes

Xiamen Justin’s commitment to quality is backed by several international certifications. As of 2025, the company holds BSCI, ISO9001, and USGA certifications, solidifying its reputation as a trusted manufacturer.

"Xiamen Justin has earned BSCI, ISO9001, and USGA certifications during its 30 years in the industry, establishing its credibility among renowned brands."

Their production facilities include standard and high-craftsmanship production lines equipped with CNC milling machines and advanced testing tools. For clients with tournament-level requirements, USGA-compliant options are available. Every unit undergoes robotic testing to ensure consistent quality. Once completed, products are stored in a monitored warehouse, ensuring they maintain their integrity.

Production Capacity and Lead Times

Xiamen Justin’s advanced manufacturing capabilities are matched by its impressive production capacity. Operating out of a 4,000-square-meter workshop with state-of-the-art machinery, the company ensures an average lead time of just one month, while prototypes can be ready in as little as 7–10 days. For specialized products, they manufacture 8,000–10,000 pieces of park golf equipment monthly, with thousands of open molds available for client selection.

8. Dongguan Changrong Sporting Goods Co., Ltd.

Founded in 2007, Dongguan Changrong has carved out a strong position in the bag manufacturing industry over the past 18 years. Operating from a 6,000-m² (64,583 ft²) facility and supported by a team of 180 skilled staff, the company has earned certifications like ISO9001, Sedex, and BSCI, and successfully passed the Kmart audit, showcasing its commitment to quality and compliance.

With a focus on their "Quality First" principle, Dongguan Changrong has gained the trust of clients worldwide. Their integrated approach – combining sales, design, and quality assurance teams – enables them to deliver reliable, customized OEM and ODM golf bag solutions.

OEM/ODM Capabilities

Dongguan Changrong provides a wide range of OEM and ODM services, offering extensive customization options to meet diverse client needs. Their expertise includes working with advanced materials such as waterproof polyester and PU leather, along with custom branding options like full-length dividers and personalized logo printing.

As stated by Dongguan Changrong Handbag Co., Ltd.:

"We are dedicated to the development and production of OEM and ODM bags and can provide a large collection of bags such as cosmetic bags, backpacks, school bags, beach bags, laptop bags, travel bags, cooler bags, and shopping bags."

They further emphasize:

"At the same time, we are ready to manufacture bags according to the brand names and designs of clients worldwide, using OEM and CMPH services."

These customization options are backed by a robust quality assurance system, ensuring that every product aligns with client specifications.

Quality Certifications and Control Processes

Quality is at the heart of Dongguan Changrong’s operations. With a dedicated team of quality control professionals, they ensure that every product meets rigorous standards before leaving the factory. Their "Quality First" philosophy drives precise craftsmanship, enabling them to meet demanding client requirements while maintaining on-time delivery for every order.

9. Shenzhen Yihui Industrial Co., Ltd.

With over a decade of experience, Shenzhen Yihui Industrial has established itself as a reliable partner for custom golf bag manufacturing. The company specializes in offering tailored OEM/ODM services and streamlined production processes to accommodate various customization needs.

OEM/ODM Capabilities

Shenzhen Yihui provides a range of OEM/ODM services, including private mold tooling and free 24-hour design support to bring unique concepts to life. They offer PU leather in a variety of colors, such as brown, white, black, orange, and multicolor, along with options for custom logo placement and accessory integration. These services are supported by strict quality control measures to ensure every detail aligns with client expectations.

Quality Certifications and Control Processes

Quality is a cornerstone of Shenzhen Yihui’s operations. The company has earned SGS audit certification (QIP-ASI2521061), reflecting its adherence to international quality and safety standards. Their quality assurance process includes providing pre-production samples for client approval before moving to mass production. Additionally, a final inspection is conducted before shipment to confirm that all products meet the required standards. This rigorous approach ensures alignment with industry expectations and supports quick turnaround times.

Production Capacity and Lead Times

Shenzhen Yihui combines customization expertise with strong production capabilities. With a monthly production capacity of 50,000 pieces, the company can manage both small-scale custom orders and high-volume production runs. Their quality control system monitors every production phase, ensuring timely delivery. They also offer expedited services, with sample deliveries in just five days. Mass production timelines depend on order size. Below is an overview of lead times:

| Order Quantity | Lead Time |

|---|---|

| 1 – 500 pieces | 15 days |

| 501 – 1,000 pieces | 30 days |

| Over 1,000 pieces | Negotiated timeline |

For orders exceeding 1,000 pieces, lead times are determined based on specific production and delivery requirements.

10. Dongguan Hotsun Sporting Goods Co., Ltd.

Dongguan Hotsun Sporting Goods Co., Ltd. rounds out the list as a custom golf bag manufacturer known for its strong OEM and ODM services.

OEM/ODM Capabilities

Hotsun specializes in offering adaptable customization options, enabling clients to design golf bags that stand out. Their OEM services include custom logo printing and a variety of material choices, catering to a wide range of preferences. This flexibility aligns with the high standards expected from top-tier custom golf bag manufacturers in China.

The company maintains strict quality control measures to ensure every design meets market demands and customer expectations.

Factory Comparison: OEM Capabilities and Quality Features

Building on the strengths outlined earlier, this comparison focuses on key OEM capabilities and quality features. Understanding these aspects is essential for making informed sourcing decisions. Each factory in our top 10 list stands out with unique strengths and a range of customization options.

For instance, Keep Perfect Golf Gear stands out by offering an all-in-one production solution. However, other factories also bring strong customization options to the table. By comparing these varied capabilities, you can pinpoint the manufacturer best suited to meet your custom golf bag requirements.

Conclusion

China’s custom golf bag manufacturing industry offers a wide array of OEM solutions tailored to diverse business needs. The ten factories highlighted in this guide each bring their own strengths, from specialized capabilities to unique production approaches.

For instance, Keep Perfect Golf Gear streamlines the entire process, providing end-to-end services that eliminate the hassle of coordinating with multiple vendors. Other manufacturers stand out for their focus on specific production techniques or their commitment to quality.

When choosing a manufacturer, it’s essential to align their capabilities with your specific goals. If you’re looking for rapid prototyping or small-batch production, you might prioritize manufacturers with flexible systems. On the other hand, large-scale orders typically benefit from factories with established production lines and rigorous quality control processes. This careful alignment ensures a smoother partnership and better results.

Quality standards can vary, but many manufacturers in this sector meet international export certifications. To ensure success, businesses should clearly communicate their quality expectations upfront and collaborate closely with the factory’s quality assurance teams. Customization options also range widely – from simple logo embroidery to complete design overhauls – so selecting a manufacturer that fits your customization needs is crucial.

Additionally, think about your long-term business plans when selecting a partner. Factories that foster ongoing relationships with consistent orders may offer advantages like better pricing or priority scheduling. Meanwhile, for one-off or highly flexible projects, other manufacturers might be a better fit.

As China’s manufacturing landscape continues to advance with automation and improved quality control, finding the right partner can help you achieve both exceptional product quality and sustainable business growth.

FAQs

What should I look for in a custom golf bag manufacturer in China?

When choosing a custom golf bag manufacturer in China, there are a few key factors to keep in mind. First, assess their manufacturing capabilities, quality control processes, and experience with customization. A good manufacturer should use advanced machinery, adhere to strict quality checks, and work with durable materials like waterproof fabrics and reinforced stitching to ensure long-lasting products.

You’ll also want to make sure they can handle your specific customization requests, whether it’s logo placement, unique design elements, or specific material preferences. Don’t forget to verify their production capacity and check if they meet international quality standards, such as ISO certifications. These steps will help you secure a dependable partner for creating high-quality custom golf bags.

How do manufacturers in China ensure custom golf bags are high-quality and durable?

Chinese manufacturers ensure their custom golf bags are built to last and meet high-quality standards by following strict quality control measures and complying with international certifications like ISO 9001 and BSCI. These certifications guarantee that the bags meet global benchmarks for both quality and ethical manufacturing.

To make the bags durable, they rely on top-notch materials, including waterproof fabrics, reinforced stitching, and sturdy zippers. Additionally, manufacturers carry out thorough testing throughout production to ensure the bags perform well and hold up over time, offering reliability for extended use.

What is the typical production time and capacity for custom golf bag orders from manufacturers in China?

When ordering custom golf bags from Chinese manufacturers, you can generally expect production times to fall between 15 and 20 days. The exact timeline depends on how intricate the design is and the level of customization involved.

Production capacity varies widely among manufacturers. Larger factories are capable of producing as many as 500,000 units per month, while smaller operations handle closer to 20,000 units monthly. This flexibility allows manufacturers to cater to both bulk orders and smaller, more tailored requests, ensuring deadlines are met without compromising on quality.