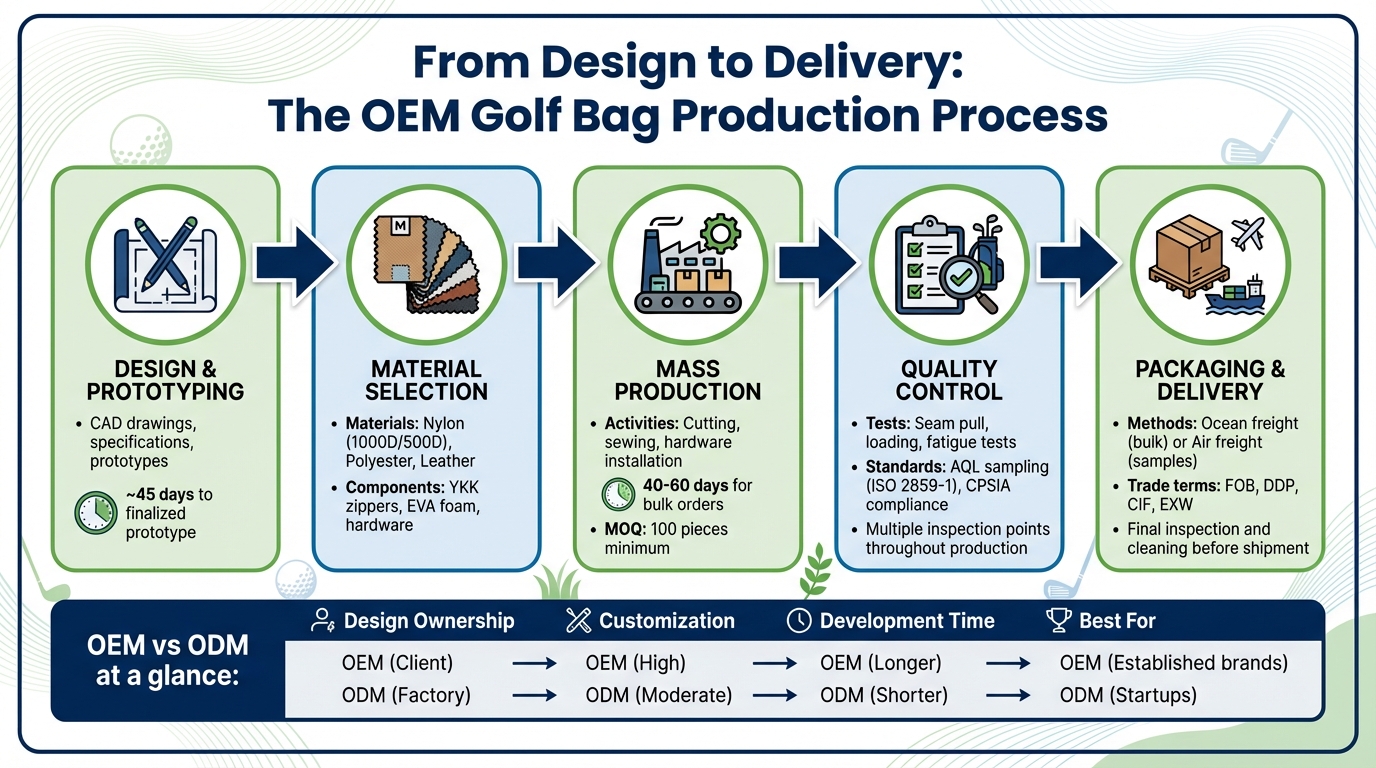

The process of creating custom golf bags involves several steps, from initial design to final delivery. Whether you’re an established brand or a startup, understanding OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) methods is crucial. OEM lets you control every detail of the design, while ODM offers pre-designed templates with minor customization options.

Key stages include:

- Design and Prototyping: Create detailed specifications, CAD drawings, and prototypes to refine the product.

- Material Selection: Choose durable fabrics like nylon, polyester, or leather, along with high-quality hardware.

- Mass Production: Factories follow approved samples to ensure consistency and quality.

- Quality Control: Multiple inspections ensure products meet U.S. safety standards and performance expectations.

- Packaging and Delivery: Proper packaging and shipping methods ensure safe delivery, with options like FOB, DDP, or CIF for logistics.

For U.S. golf brands, custom golf bags offer a way to combine performance and branding, with features like waterproof materials, ergonomic straps, and tailored compartments. Production timelines typically range from 40 to 60 days for bulk orders. Partnering with experienced manufacturers, like Manter o golfe perfeito, simplifies the process and ensures high standards.

| Manufacturing Approach | OEM | ODM |

|---|---|---|

| Design Ownership | Client | Factory |

| Personalização | High | Moderate |

| Development Time | Longer | Shorter |

| Ideal For | Established brands with unique designs | Startups or quick market launches |

Custom golf bags balance functionality and style, making them essential for brands aiming to stand out in the competitive U.S. market.

OEM Golf Bag Production Process: 5 Stages from Design to Delivery

How Golf Bags Are Made? 🏅 Inside a Professional Golf Bag Factory Tour

Design and Concept Development

The journey to creating a custom golf bag begins with a conversation – one that ensures the design aligns with both your brand’s goals and your customers’ expectations. This crucial step sets the foundation for a bag that resonates with your audience. For instance, understanding whether your target golfers prefer walking the course or riding in carts will help decide between a lightweight stand bag or a spacious cart bag.

"Getting a custom golf bag is a straightforward process involving choosing the right manufacturer, selecting materials, and personalizing design elements like color, logos, and compartments." – Eric, OEM/ODM Bag Expert, Szoneier

Key functional elements are also considered at this stage. These include the number and type of pockets – such as insulated ones for drinks or lined ones for valuables – strap comfort, handle placement, and club divider setups. For example, full-length dividers can help keep clubs organized and tangle-free during transport. On the branding side, manufacturers typically require high-resolution logo files, Pantone color codes, and embroidery details, such as names or initials. This early collaboration ensures that all design elements are tailored to meet your needs.

Gathering Requirements and Design Specifications

After the initial discussions, manufacturers dive deeper into specifics, gathering detailed input about your target audience and their preferences. For example, if your customers often play in rainy conditions, you might prioritize features like waterproof zippers and weather-resistant materials, such as treated polyester or neoprene. For professional or tour-level bags, it’s essential to maximize storage and branding space to accommodate sponsorship logos.

If you’re new to the OEM process, requesting physical fabric samples or a color card is a smart move. These samples help confirm material quality and color accuracy before proceeding. Additionally, precise measurements – such as the circumference of club heads and the desired length down the shaft – are critical to ensure that custom covers and compartments fit perfectly.

Creating Technical Designs and Prototypes

Once the requirements are nailed down, manufacturers create detailed CAD drawings and tech packs. These documents outline dimensions, layouts, and hardware specifications. Digital mockups are then used to refine the design, ensuring proportions and functionality are just right before moving forward. Patterns are developed to guide precise cutting and assembly, minimizing material waste.

The first physical prototype plays a key role in testing the bag’s durability, usability, and fit. Manufacturers often send digital proofs for your review within a few days. This step allows you to make adjustments and confirm that the design meets your expectations. After fine-tuning the prototype, the design is finalized and moves into production planning.

Approval and Revision Process

Most manufacturers include two rounds of revisions in the initial purchase price, giving you the chance to fine-tune the bag’s layout. After reviewing digital proofs, you’ll approve key elements like embroidered panels or specific components before the full assembly begins. It’s important to confirm the final prototype in writing to lock in specifications and avoid unexpected changes down the line.

The approved "gold sample" serves as the quality standard for the entire production run. Once you give the green light – often after reviewing high-resolution photos of the completed bag – the manufacturer can proceed to mass production. From the initial design phase to the finalized prototype, the entire process typically takes about 45 days.

Material Selection and Prototyping

Choosing the right materials for a golf bag is crucial for ensuring durability, weight balance, and resistance to varying weather conditions across the U.S. – whether it’s Florida’s humidity or Colorado’s intense sunlight. These decisions directly impact the bag’s performance and longevity while aligning with the design standards set earlier in the process.

Key Materials and Components Used in Golf Bags

Nylon stands out as a favorite due to its impressive strength-to-weight ratio. Among the options, 1000D nylon is known for its unmatched durability, while 500D nylon offers more flexibility.

"Nylon is the most popular material used in modern golf bags, prized for its exceptional strength-to-weight ratio and versatility." – Sarah Johnson, textile engineer

Polyester is another go-to material, valued for its ability to resist UV fading and its quick-drying properties – perfect for sunny days on the course.

For premium waterproofing and extra tear resistance, laminates like X-Pac® or VX are often used in high-end bags.

"1000D nylon is still the benchmark by which all other bag fabrics are measured. It is extremely durable with a plain weave construction that provides a minimalist industrial aesthetic." – Mission Workshop

Luxury cart bags often feature full-grain leather, a material that retains its tough outer layer and can last over 30 years with proper care – some even surviving up to a century before degrading. Meanwhile, synthetic (PU) leather offers a sleek, premium appearance, combining water resistance with reduced weight and cost compared to genuine leather.

High-quality golf bags also incorporate thoughtful details like EVA foam padding for comfort, velvet-lined compartments for delicate items, and durable hardware such as waterproof YKK zippers and corrosion-resistant brass or aluminum components. Since these bags are typically designed to carry 12–14 clubs, the materials must withstand significant weight without stretching or losing shape.

Testing Prototypes for Functionality and Performance

Prototypes play a key role in ensuring the bag delivers on functionality and performance. One of the first tests involves assessing weight distribution to ensure the bag remains balanced when fully loaded with clubs, reducing strain on the golfer’s back. Stability and durability of stand legs, often made from aluminum or carbon fiber, are also carefully evaluated.

Zippers and weather-resistant coatings undergo cycle testing to confirm their reliability in real-world conditions. Simulated carrying sessions help assess strap comfort, while pocket accessibility is tested to ensure golfers can easily retrieve rangefinders, valuables, or drinks stored in insulated compartments.

"For each order we create a prototype for your approval. From our two wholly-owned sample development facilities in China you will be able to test the functionality of your design." – Travelon

Once the prototype passes these rigorous tests, it becomes the blueprint for mass production. With its performance validated, the production process moves forward with a focus on maintaining quality at every step.

Mass Production and Quality Control

Once the final prototype gets the green light, it’s time to shift gears into full-scale production. This stage turns a single approved sample into hundreds – or even thousands – of identical bags, all crafted to meet the high standards expected in the U.S. market.

Pre-Production and Manufacturing Setup

The journey begins with the creation of a Pre-Production Sample (PPS), which acts as the benchmark for the entire production run. Once the client signs off on this sample, the factory keeps an identical reference to ensure every bag in the batch matches up. From there, production planning kicks into gear, taking into account the order size and delivery deadlines, which usually fall between 15 and 35 days, depending on the complexity of the design. Factories are flexible, handling orders as small as 100 pieces.

Materials like nylon, polyester, or leather are cut with precision to reduce waste and guarantee a perfect fit during assembly. Branding is tackled early on, with logos applied using techniques like silk-screen printing (with a mold setup fee of about $20), heat transfer (often provided at no extra cost for intricate designs), embroidery, or stamped leather logos. These steps lay the groundwork for a smooth production process in the next phase.

Main Manufacturing Steps

The manufacturing process begins with industrial sewing machines stitching together the outer panels, using high-strength threads for durability. Once the exterior is ready, the lining is added. Next comes the hardware installation, where workers attach zippers, sturdy bases, support stands, and wheels. Straps and grips are carefully adjusted to ensure they’re comfortable and slip-resistant.

Throughout production, the factory relies on the reference sample to maintain consistency. Precision tools and standardized procedures help ensure each bag is assembled to the same high standard. After assembly, the bags undergo a series of rigorous quality checks to confirm they meet the required specifications.

Quality Control and Inspection Procedures

Quality control isn’t just a one-and-done process – it happens at multiple stages. Inspectors check everything from the strength of the stitching to the durability of the zippers and the structural integrity, all while comparing each unit to the approved PPS. For U.S.-bound shipments, factories follow AQL (Acceptable Quality Limits) sampling, based on ISO 2859-1 standards, to determine how many units to inspect and the acceptable defect rate.

"Quality control (QC) refers to the systematic process of ensuring that each bag produced meets the required standards… QC isn’t just a final inspection; it’s an ongoing commitment that starts from the very first design." – Zoey Lee, Business Partner, Osgoodway

Final inspections confirm compliance with U.S. safety regulations, like the CPSIA (Consumer Product Safety Improvement Act) and California Proposition 65, ensuring the materials are free from restricted substances like heavy metals and phthalates. Bags also undergo seam pull tests, loading tests, and fatigue tests to simulate real-world usage over time. Only after passing these stringent checks are the bags approved for packaging and storage.

sbb-itb-4fa7e8b

Packaging, Logistics, and Delivery

Once the quality control process is complete, the attention shifts to packaging and logistics, ensuring that products reach U.S. customers safely and efficiently.

Packaging Standards for U.S. Shipments

Before packaging begins, trained staff meticulously clean each bag and conduct a final inspection to confirm its appearance, structure, and functionality. Brands typically supply detailed packaging instructions, which the factory follows during this critical stage.

Each bag is then placed into cartons designed to meet the client’s specific requirements. These cartons undergo rigorous drop and compression tests to simulate real-world shipping conditions. This step is especially important for ocean freight, where containers are often stacked and subject to movement during transit.

Shipping Methods and Delivery Coordination

With the products securely packaged, the next step is to determine the shipping method and clarify delivery responsibilities.

Choosing the right shipping option depends on factors like cost, speed, and order size. Ocean freight is the go-to choice for bulk shipments due to its cost efficiency, while air freight is preferred for faster delivery or smaller sample orders. While air freight offers speed, it comes with a higher price tag compared to ocean freight.

Another key element is defining responsibilities using Incoterms. For example:

- FOB (Free on Board): The seller handles costs up to the port, while the buyer manages freight and U.S. customs.

- DDP (Delivered Duty Paid): The seller covers all expenses, including shipping and import duties, to the buyer’s location.

- EXW (Ex-Works): The buyer assumes full responsibility for transportation and export/import processes.

- CIF (Cost, Insurance, Freight): The seller pays for shipping and insurance to the destination port, with the buyer handling import duties.

Early agreement on these terms avoids confusion over responsibilities like customs clearance and final delivery.

Total landed costs include not just the product price but also export handling, freight, insurance, import duties, brokerage fees, and compliance costs. For ocean freight, rate fluctuations and tariffs can add between $0.20 and $0.60 per dozen units. To navigate U.S. import regulations and ensure smooth customs clearance, many companies work with a customs broker. Bulk orders typically require 40 to 60 days for production, with payment terms often split into 30% upfront and 70% before shipment.

| Trade Term | Responsibility Breakdown |

|---|---|

| FOB (Free on Board) | Seller covers costs to the port; buyer handles freight and U.S. customs |

| DDP (Delivered Duty Paid) | Seller manages all costs, including shipping and import duties, to the buyer’s location |

| EXW (Ex-Works) | Buyer assumes full responsibility for transportation and export/import processes |

| CIF (Cost, Insurance, Freight) | Seller covers shipping and insurance to the destination port; buyer manages import duties |

"Post-delivery support includes warranty, repair protocols, and reorder automation." – Eric, Founder, Szoneier

This final logistics phase ensures that your custom golf bags maintain the same high standards established during the design and production process.

Partnering with Manter o golfe perfeito for OEM Projects

Why Choose Keep Perfect Golf

With over 20 years of experience in OEM and ODM golf bag manufacturing, Keep Perfect Golf stands out as a trusted partner for creating high-quality golf bags. Their factory-direct communication ensures quicker responses and seamless coordination, making the entire process smoother for their clients.

Quality is a top priority. Every golf bag undergoes a detailed multi-stage inspection process, covering everything from material safety to stitching durability and functional testing of straps and connections. To back their commitment, they offer a 3-month satisfaction guarantee on all products.

For convenience, Keep Perfect Golf provides DDP (Delivered Duty Paid) pricing, simplifying import duties and taxes for their clients. Sample production typically takes 25 to 35 days, while bulk orders are completed within 40 to 60 days, ensuring efficient delivery timelines.

This dedication to quality, communication, and efficiency lays the foundation for custom solutions designed specifically for U.S. golf brands.

Tailored Solutions for U.S. Golf Brands

Keep Perfect Golf leverages its expertise to craft a wide variety of golf bag styles tailored for the unique demands of U.S. golf brands. Combining precision design with premium materials, they deliver bags that balance performance and style.

Their product range includes options for every need, such as cart bags with ample storage, lightweight stand bags, premium staff bags, and compact Sunday bags for quick rounds. Customization options are extensive, allowing brands to choose head divider configurations like 3-way or 5-way layouts and select from durable, high-strength waterproof nylon or robust PU leather.

For branding, Keep Perfect Golf offers multiple logo customization techniques, including embroidery, printing, embossing, and metal badges, ensuring your logo stands out on the course. Clients can also choose from a variety of fabrics, such as premium PU leather or water-resistant nylon, providing flexibility to balance cost and performance. Additionally, their manufacturing process supports small-batch production, making it an excellent choice for newer U.S. golf brands or corporate promotional events.

Conclusion

The OEM process – from initial design to final delivery – lays the foundation for creating durable, functional, and well-branded products. Each step, from selecting materials and prototyping to precision manufacturing and rigorous quality checks, builds upon the last to ensure a seamless production journey.

"Only through meticulous craftsmanship can high-quality golf bags be produced, providing players with an enhanced user experience." – Joyce Ho, Legendtimes Golf Factory

Market trends reinforce the importance of this structured approach. Establishing a "gold sample" during the prototyping phase serves as a crucial benchmark, helping to minimize waste and maintain consistent quality throughout mass production. A well-planned OEM process also fosters clear communication between the brand and manufacturer, reducing the risk of costly mistakes before large-scale production begins.

For U.S. golf brands aiming to break into or grow within this competitive market, partnering with an experienced manufacturer simplifies the entire process – from concept sketches to global logistics. With sample production timelines ranging from 25 to 35 days and bulk orders completed within 40 to 60 days, aligning product launches with these production schedules ensures brands can meet market demand effectively.

FAQs

What’s the difference between OEM and ODM in custom golf bag production?

In OEM (Original Equipment Manufacturer) production, you create the design, and the factory produces the golf bags based entirely on your specifications. This approach gives you complete control over every detail of the design and ensures full ownership of the finished product.

Por outro lado, ODM (Original Design Manufacturer) production relies on the factory’s existing designs, which you can tweak with minor changes like adding your logo or adjusting colors. This route is usually quicker and more budget-friendly but limits your control over the design and ownership rights.

Deciding between OEM and ODM comes down to your priorities – whether you want total customization and ownership or a faster, more economical option.

Why is material selection important in custom golf bag performance?

When it comes to custom golf bags, the materials used can make all the difference in performance and usability. Durable materials not only stand up to wear and tear but also offer protection against water, keeping your clubs safe in unpredictable weather. Plus, selecting lightweight yet sturdy materials ensures the bag remains easy to carry while holding up over time. Ultimately, the right choice of materials makes the bag more comfortable to use and increases its reliability for every round of golf.

What are the steps in the quality control process for OEM golf bags?

The quality control process for OEM golf bags is designed to ensure that each product meets strict standards for durability, functionality, and design. It all starts with a thorough inspection of raw materials as soon as they arrive, ensuring they align with the required specifications.

Throughout production, key checkpoints – like sewing and assembly – are carefully monitored to identify and address any potential issues early in the process. Once production is complete, every bag goes through a final inspection to assess its appearance, structural strength, and overall functionality. Additionally, random sample testing is conducted to confirm consistency across the batch.

These meticulous steps work together to ensure that every golf bag meets the expected standards of quality before it’s shipped out.

Related Blog Posts

- From Design to Delivery: A Behind-the-Scenes Look at Our Custom Process

- How to Choose a Premium Golf Bag Manufacturer for Seamless Production

- Inside Look: The Full Manufacturing Process of Golf Bags Explained

- What are the most effective B2B procurement strategies for sourcing custom-manufactured golf bags, and how do they differ from sourcing off-the-shelf products?