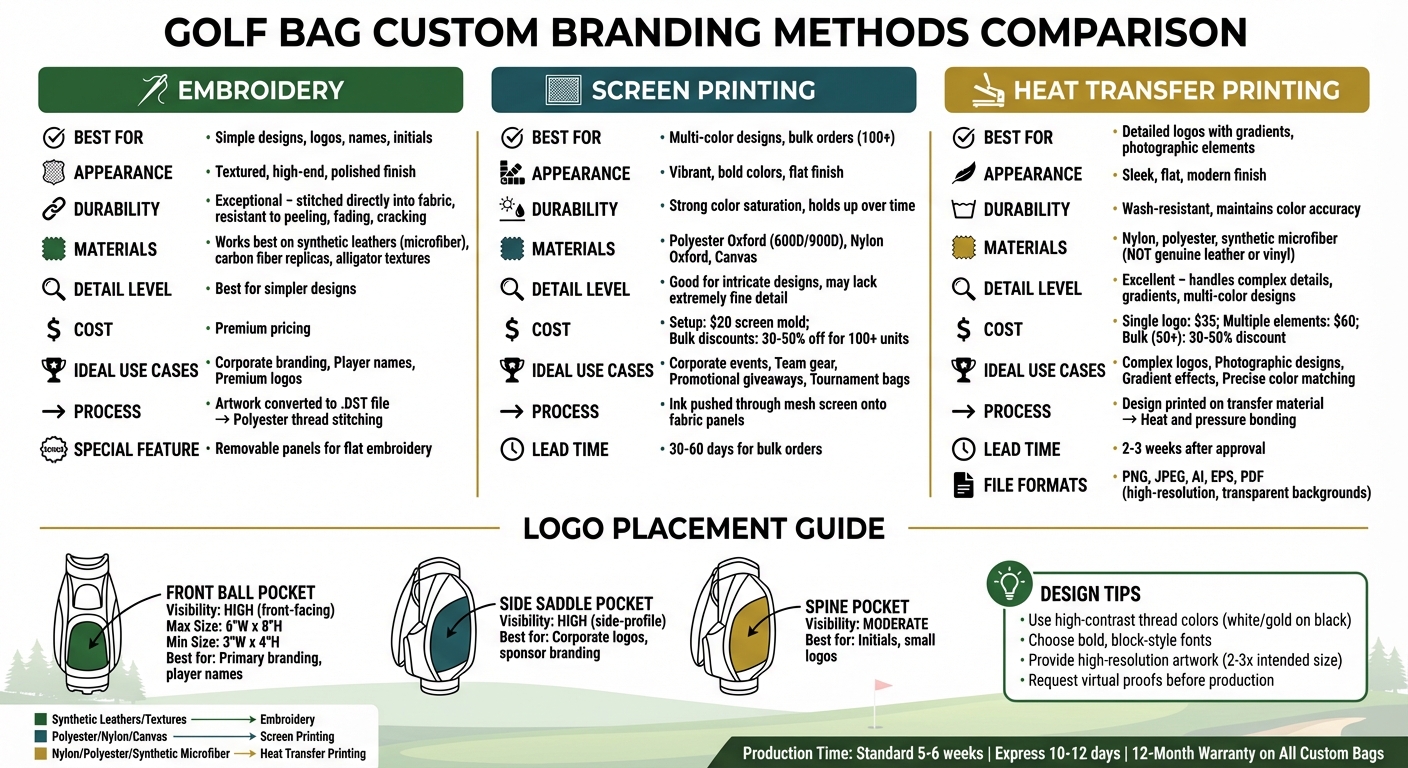

Customizing golf bags with branding is an effective way to promote your business or personal style on the course. Whether you’re a company looking for a professional touch or an individual golfer wanting a personalized look, methods like embroidery, screen printing, and heat transfer printing offer tailored solutions. Here’s what you need to know:

- Embroidery: Durable, polished, and ideal for simple designs like logos, names, or initials. Works best on synthetic leathers and offers a high-end, textured finish.

- Screen Printing: Perfect for bulk orders and multi-color designs. Produces vibrant results on materials like Polyester Oxford but may lack the fine detail of other methods.

- Heat Transfer Printing: Best for detailed, sharp logos with gradients or photographic elements. Provides a sleek, flat look and works well on synthetic fabrics.

Strategic logo placement, such as the front ball pocket or side panels, maximizes visibility. Materials like microfiber leather or nylon ensure durability and compatibility with these techniques. Companies like Keep Perfect Golf handle the entire process, from design to delivery, ensuring your golf bag reflects your brand or personal style effectively.

Custom golf bags are more than gear – they’re a statement. Whether for corporate programs, tournaments, or personal use, they combine function and branding in a way that stands out.

Golf Bag Branding Methods Comparison: Embroidery vs Screen Printing vs Heat Transfer

Transform Your Golf Bag with Stunning DIY Embroidery in Minutes

Embroidery for Long-Lasting Logos

Embroidery involves stitching your logo directly into the fabric of the bag, creating a durable and polished finish. The process begins with converting your artwork into a .DST file, which acts as a guide for each stitch and thread change. This ensures precision, making your logo consistently sharp and professional. It’s a process that guarantees your logo stands up to both time and wear.

Most embroidery uses polyester thread, known for its strength, vibrant colors, and resistance to fading. Many modern golf bags are designed with convenience in mind, featuring removable front ball-pocket panels that unzip completely. This allows the fabric to lay flat on the embroidery machine, ensuring optimal results every time.

"Golf bag embroidery is more than just a trend – it’s a statement. Imagine turning a standard golf bag into a canvas that reflects your personality, achievements, or even a dash of humor." – Cathy Chen, MaggieFrames

Benefits of Embroidered Golf Bags

Embroidered logos offer a textured, high-end look that exudes quality and professionalism. Unlike iron-on patches or heat transfers that rely on adhesives, embroidery stitches the design directly into the material. This makes it exceptionally durable, resistant to peeling, fading, or cracking. It’s particularly effective on synthetic leathers like microfiber, which are known for their excellent wear resistance.

This method works best for simpler designs, such as names, initials, or crests. For maximum impact, choose thread colors that contrast boldly with your bag’s fabric – think white or gold on a black background. This ensures your design remains clear and easy to read, even from a distance on the course.

Where to Place Embroidered Logos

The placement of your embroidered logo can greatly enhance its visibility and impact. The front ball pocket is the most popular spot, offering prime visibility for player names or primary branding. Side saddle pockets are ideal for larger corporate logos or sponsor branding, while the spine pocket works well for initials or smaller logos.

To plan the perfect placement, use painter’s tape to mark the position of your logo. Opt for bold, block-style fonts to ensure clarity. For challenging areas that can’t be fully hooped, professionals often use a "floating technique", which involves placing a stabilizer under the fabric without hooping the entire bag.

| Location | Best For | Visibility Level |

|---|---|---|

| Front Ball Pocket | Primary Branding / Player Name | High (Front-facing) |

| Side Saddle Pocket | Corporate Logos / Sponsor Branding | High (Side-profile) |

| Spine Pocket | Initials / Small Logos | Moderate |

Screen Printing for Multi-Color Designs

Screen printing is a method where ink is pushed through a mesh screen onto fabric panels, making it a great option for multi-color and intricate designs that might be too detailed for embroidery. This process produces bold, vibrant colors, though it may not capture extremely fine details as precisely. Its ability to deliver strong color makes it a popular choice for larger orders.

"Silk screening printing is a process where ink is transferred onto a golf bag’s surface through a mesh screen. This technique is perfect for vibrant and detailed designs and offers great color saturation and durability." – Oneier

There is an initial setup cost of around $20 to create the silk screen mold. However, the cost per unit drops significantly when ordering in bulk. For orders of 100 or more, bulk discounts can reduce prices by as much as 30% to 50%.

Why Use Screen Printing

Screen printing is ideal for bulk orders, making it a go-to option for corporate events, team gear, and promotional giveaways. While embroidery provides a premium, textured appearance, screen printing stands out for its affordability and ability to handle intricate, multi-color designs on a larger scale.

This technique works especially well on materials like Polyester Oxford (600D or 900D), which holds colors effectively, ensuring logos stay crisp over time. Nylon Oxford and Canvas are also excellent choices, offering durability while preserving the printed design during regular use. For the best results, ensure the bag’s surface is clean and free of dust or oils to help the ink adhere properly and achieve a polished look.

These qualities make screen printing a versatile option for a variety of bag styles and designs.

Screen Printing on Different Golf Bag Types

Screen printing’s affordability and vibrant results make it a great fit for a range of golf bag styles offered by Keep Perfect Golf. For example, cart bags feature large, flat panels that are perfect for bold logo displays. Stand bags, which are lightweight and come with retractable legs, are ideal for walking golfers who want visible branding without extra bulk. Tour or staff bags, with their ample surface area, are perfect for showcasing detailed patterns or multiple sponsor logos.

To achieve the best outcome, provide high-resolution artwork in formats like Adobe Illustrator (.ai) or PDF, which ensures precise screen creation. Lead times for bulk production typically range from 30 to 60 days, depending on the size and complexity of the order.

Heat Transfer Printing for Sharp, Detailed Logos

Heat transfer printing provides a polished, modern finish, making it perfect for intricate logos and designs. Unlike embroidery or screen printing, this method ensures every detail is crisp and professional. By bonding the logo or name directly onto the bag’s surface, it creates a flat, sleek look that handles complex details like gradients, fading effects, and photographic elements with ease. This makes it an excellent choice for designs with multiple colors or fine details.

"Heat transfer is a sleek, modern printing method that bonds your name or logo to the bag’s surface. It’s affordable, sharp, and durable, ideal for most custom logos." – CaddyDaddy

Pricing starts at about $35 for a single name or logo, while combining multiple elements can cost around $60. Bulk orders of 50 or more bags often qualify for discounts between 30% and 50%.

How Heat Transfer Printing Works

For the best results, high-resolution digital files (PNG, JPEG, AI, EPS, or PDF) with transparent backgrounds are required. The design is printed onto a special transfer material and then bonded to the bag using heat and pressure. The result? A durable, vibrant finish that holds up to regular use and cleaning.

This method also allows for precise color matching and detailed artwork that remains intact wash after wash. Turnaround time is typically 2 to 3 weeks after the virtual mock-up is approved. To ensure the best outcome, provide artwork enlarged 2–3 times its intended size and request a virtual proof to confirm positioning and color accuracy before production begins.

Using Heat Transfer with Keep Perfect Golf Materials

Heat transfer printing works exceptionally well with modern synthetic fabrics, making it ideal for Keep Perfect Golf’s custom materials. Durable synthetics like nylon and polyester are particularly compatible, as they withstand the heat application process and maintain the design’s integrity over time. Keep Perfect Golf uses synthetic materials specifically optimized for this printing method.

However, heat transfer is not suitable for genuine leather or vinyl, as high temperatures can damage these surfaces. Additionally, textured finishes like carbon fiber replicas or alligator patterns are not recommended for this method. On the other hand, synthetic microfiber leather supports both embroidery and printing, offering greater flexibility in design choices.

To maintain bags with heat-transferred logos, clean gently with a soft cloth and mild detergent, taking care around the printed area. Avoid direct sunlight or artificial heat sources when drying, as these can cause warping or fading. With proper care, your logo will stay sharp, preserving your brand’s polished image.

sbb-itb-4fa7e8b

Logo Placement for Better Visibility

Strategic logo placement works hand-in-hand with your chosen printing methods to make your branding stand out. Where your logo is placed on a golf bag can significantly impact how often it’s noticed. A well-thought-out position ensures your logo remains visible whether the bag is being carried, sitting on a cart, or stored away. Let’s explore the best spots for maximum visibility.

Best Spots for Golf Bag Logos

The front ball pocket panel is widely regarded as the prime location for logo placement. Many golf bags include a removable front panel with a perimeter zipper, specifically designed for customization. This area not only delivers a polished, professional look but is also one of the most visible spots during gameplay.

"The removable panel is almost always the front-most pocket, where you typically store golf balls and tees… this is, without a doubt, the cleanest and most popular method for a professional-looking result." – Spencer Lanoue, Founder, Caddie AI

Other great options include side panels, backpack straps on stand bags, and outward-facing pockets on cart bags, all of which ensure excellent visibility. For tour and staff bags, the larger outer areas are perfect for showcasing sponsor logos.

If you’re looking for a temporary branding solution, custom tags can be attached to the main carry handle or metal towel ring. To make your logo pop, use high-contrast thread colors – like white or red on a black bag – and stick to bold, block-style fonts for better visibility from a distance.

Logo Size and Position Options

Keep Perfect Golf offers flexibility when it comes to logo dimensions, tailoring them to the placement location. The ball pocket provides the most room, accommodating logos up to 6 inches wide by 8 inches tall, with a minimum size of 3 inches wide by 4 inches tall to ensure clarity. Many customers opt for slightly smaller sizes to maintain harmony with the bag’s design.

| Location | Max Width | Max Height | Min Width | Min Height |

|---|---|---|---|---|

| Ball Pocket | 6 inches | 8 inches | 3 inches | 4 inches |

| Shag Bags, Den Caddies | 6 inches | 6 inches | 3 inches | 4 inches |

| Shoe Bags | 3.25 inches | 3 inches | 1 inch | 1 inch |

| Valuables Pouches | 3.25 inches | 3.25 inches | 1 inch | 1 inch |

Before committing to a placement, take a photo of the pocket panel to confirm the orientation of your logo. This step ensures the design appears upright when the bag is standing. Avoid placing logos near zippers, retractable legs, or shoulder straps to preserve both the bag’s functionality and aesthetic appeal.

Material and Design Options with Keep Perfect Golf

Selecting the right materials and design features is key to making your brand stand out both on and off the golf course.

Fabric Choices for Custom Golf Bags

The fabric you choose plays a major role in determining the look and durability of your branded golf bag. One of the most popular options is microfiber leather (synthetic), known for its excellent wear resistance and polished finish, which works perfectly with embroidery designs. For lightweight stand bags, nylon is a practical choice – ideal for golfers who prefer walking the course. However, nylon is better suited for simpler logos to avoid wrinkling.

Looking for a sleek, modern vibe? Carbon fiber replicas offer a high-tech aesthetic and work well with embroidery. For a more upscale appearance, alligator skin textures deliver a luxurious feel and are compatible with embroidery, though they don’t support printed designs. If you want something bold, metallic or gloss finishes create eye-catching, high-shine bags. Keep in mind, though, that metallic finishes can fade with long-term sun exposure, and neither metallic nor gloss finishes are ideal for printing.

When durability matters most, embroidery on microfiber leather is the go-to option for a polished and long-lasting result.

Color and Pattern Selection

Keep Perfect Golf provides Pantone-matched custom colors to align perfectly with your brand identity. For an additional US$200, you can opt for custom Pantone colors or specialized patterns created through screen or sublimation printing. Sublimation is particularly effective for complex designs, photos, or gradient effects that stitching can’t achieve.

If you’re choosing embroidery, it’s important to select thread colors that either complement the bag’s accents or create a strong contrast. For instance, white thread on a black bag ensures your logo stands out clearly.

These tailored color and pattern options simplify the production process while ensuring your design is executed with precision and quality.

Complete Production and Quality Control

Once you’ve selected your bag model and customized it online, Keep Perfect Golf’s design team will deliver mock-ups within 24–48 hours. During the design phase, you’ll also receive embroidery samples, or “stitch-outs,” to confirm the quality of your logo before full production begins. Standard production takes 5–6 weeks, but if you’re in a hurry, express orders can be completed in just 10–12 days at a cost of US$450 per bag.

Before shipping, you’ll receive final photos to confirm colors, logos, and stitching details. Every custom bag is backed by a 12-month warranty that covers materials, craftsmanship, and structural hardware.

Conclusion

Custom branding transforms any golf bag into a moving advertisement for your brand. Whether you opt for embroidery, screen printing, or heat transfer printing, these methods allow for personalized, cost-effective designs. As CaddyDaddy aptly states: "A custom golf bag isn’t just about style. It’s about identity, professionalism, and leaving an impression".

Keep Perfect Golf takes this concept further by managing every step of the process – from material selection and design mockups to quality control and global delivery. With choices like microfiber leather and custom Pantone colors, you can craft a bag that perfectly reflects your brand. Standard production takes 5–8 weeks, but express options can have your order ready in as little as 10–12 days. Plus, each bag comes with a 12-month warranty covering materials and craftsmanship.

This all-inclusive approach ensures your custom golf bag becomes much more than just a piece of equipment – it’s a bold statement of your brand. Whether you’re outfitting a corporate team, showcasing your business at tournaments, or creating a standout personal look, these bags are attention-grabbing brand ambassadors on the green.

Looking to make a lasting impression? Keep Perfect Golf combines expert design, premium materials, and meticulous quality control to deliver a custom golf bag that’s as functional as it is striking. With cutting-edge printing techniques and exceptional craftsmanship, your golf bag becomes a seamless extension of your brand’s identity.

Preguntas frecuentes

What materials work best for customizing golf bags?

The top materials for customizing golf bags include polyester, nylon, canvasy leather. Each brings its own strengths, depending on the look and functionality you’re aiming for.

Polyester is a favorite because it’s lightweight, water-resistant, and holds colors exceptionally well. This makes it great for techniques like screen printing, embroidery, or heat transfer. Nylon is another durable option, with a smooth surface that pairs nicely with most printing methods. If you’re after a textured, sturdy feel, canvas is a solid choice, especially for embroidered logos. For those wanting a premium, classic vibe, leather delivers a luxurious touch. It’s perfect for embroidery or debossing, though it does come with a higher price tag.

These materials work seamlessly with popular branding techniques, ensuring your designs are durable, vibrant, and eye-catching on the course.

What’s the difference between heat-transfer printing and embroidery for custom golf bag logos?

Heat-transfer printing shines when it comes to detailed, multicolored logos, as it can capture fine lines and gradients with impressive accuracy. It’s also a budget-friendly option for smaller orders thanks to its lower setup costs. That said, while the finish looks great initially, it tends to be moderately durable and may show signs of fading with heavy use over time.

Embroidery, in contrast, delivers a premium, textured finish that’s built to last. It’s best suited for simpler designs or solid-color logos since the stitching process limits the level of detail. Although it requires more time and a higher upfront cost to set up, embroidery offers a polished, long-lasting look that stands up well against wear and tear.

If your design is intricate and packed with color, heat-transfer printing is your go-to option. But for a timeless, durable finish with a touch of elegance, embroidery is the clear winner.

What is the best spot to place my logo on a golf bag for maximum visibility?

For the best visibility, position your logo on the front-center panel of the golf bag. This spot is the most noticeable, whether the bag is on a cart, a stand, or resting on the ground. If you’re looking for an additional placement, the fold above the small side pocket is a great option – it stays visible even when the bag is open.

Here’s how to make your logo stand out:

- Size and contrast: Opt for a logo size of about 3–4 inches wide, and choose colors that contrast well with the bag’s background for maximum visibility.

- Placement: Place the logo roughly 2–3 inches below the top strap to avoid interference from handles or straps.

- Avoid seams: Steer clear of stitching or zippers to prevent distortion during printing or embroidery.

By paying attention to these details, your logo will leave a lasting impression both on the course and beyond.

Related Blog Posts

- How to Brand Golf Bags for Corporate Events: A Step-by-Step Guide

- Por qué los golfistas profesionales prefieren las bolsas personalizadas: Historias y asociaciones de marcas

- Bolsas de golf personalizables: Las tendencias de personalización se imponen

- From Design to Delivery: The OEM Golf Bag Production Process Explained