Partnering with a one-stop golf bag design and manufacturing service simplifies the process of creating high-quality, custom golf bags. Instead of managing multiple vendors, you work with a single provider that handles everything from design and material selection to production, quality checks, and delivery. This approach reduces delays, ensures consistent quality, and saves costs by eliminating middleman markups.

Key Takeaways:

- Efficiency: One provider oversees the entire process, minimizing delays and miscommunication.

- Cost Savings: Lower coordination fees and better bulk material pricing.

- Customization: Wide options for personalized designs, materials, and features.

- Quality Control: Strict checks at every stage for durability and consistency.

- Faster Delivery: Centralized management speeds up production and shipping.

For businesses, this model is ideal for branded merchandise or event giveaways, while individual golfers can create personalized bags that match their style and needs. With the U.S. golf bag market projected to grow to $2.32 billion by 2030, choosing a streamlined manufacturing partner ensures you stay competitive and meet rising demand effectively.

Golf Bag Review:Crafted to Perfection: Discover the Ultimate Custom Golf Bags at Our Factory

How One-Stop Services Simplify the Custom Golf Bag Process

The traditional way of creating custom golf bags often involves juggling multiple vendors, each handling a different part of the process. This fragmented approach can lead to delays, miscommunications, and added stress. A one-stop service, however, brings everything together under one roof, streamlining the journey from design to delivery.

Simple End-to-End Workflow

With a single provider handling every step, the process becomes much smoother. It starts with a design consultation, where you can share your vision – whether it’s a stand bag with your initials or a set of branded cart bags for an upcoming corporate event. During this phase, you’ll explore options like colors, fabric types, logo placement, and text styles. Choices range from lightweight, weather-resistant materials to more classic or premium finishes, all tailored to balance performance and aesthetics.

Once the design is finalized, a prototype is created for you to review. This step allows you to test the bag’s functionality and request adjustments before full production begins. After you give the green light, manufacturing kicks off with your exact specifications in place. Quality checks are performed throughout the process to catch any potential issues early. Finally, the finished product is professionally packaged and delivered to your preferred location.

For added convenience, consider integrating features like a GPS holder or a dedicated pocket for electronic gadgets – perfect for keeping your devices safe and accessible during a round of golf.

This streamlined approach not only simplifies the process but also ensures quick communication and efficient problem-solving.

Better Communication and Faster Delivery

One of the standout benefits of a one-stop service is the improved communication it offers. With design and manufacturing teams working closely together, production speeds up significantly. For instance, a CNC coordinator resolving a tolerance issue on the spot highlights how direct communication can prevent delays.

Encouraging open communication on the production floor also helps catch potential errors early. Clear and consistent updates ensure that everyone – designers, manufacturers, quality control, and shipping teams – stays on the same page. Having a single point of contact to address concerns and provide real-time updates further enhances efficiency. This results in faster delivery times compared to the slower, multi-vendor approach.

For American customers, who often expect quick and reliable service, this streamlined process delivers on those high standards, ensuring a smooth and timely experience.

Cost Savings and Value

When it comes to simplifying operations, the financial perks of a one-stop solution are hard to ignore. Take custom golf bag manufacturing, for instance: instead of juggling multiple vendors, each with their own invoices and fees, you can opt for a unified process that keeps more money in your wallet.

Lower Costs Through Single-Source Production

Choosing a single provider can cut out hidden costs by reducing coordination fees, eliminating middleman markups, and enabling better bulk material negotiations. Working directly with the factory not only trims unnecessary expenses but also improves quality control. A great example is Prince Grip Company, which in 1993 outsourced its manufacturing, warehousing, and shipping to one provider. The result? They quickly captured 15% of the global market share. Plus, having one team handle the entire process means they can identify and resolve issues early, cutting down on waste and minimizing rework.

Clear Pricing and Billing

Financial clarity is another big win. Transparent pricing makes life easier, especially for American businesses that prioritize straightforward billing. A one-stop provider typically quotes in U.S. dollars and consolidates everything into a single invoice. This eliminates the headache of managing multiple payments and simplifies accounting. With predictable pricing, budgeting becomes easier, and you can avoid surprise fees that might throw off your project’s finances.

sbb-itb-4fa7e8b

Quality Control and Customization Options

Streamlined processes and better communication are just part of the story. Quality control and customization take the one-stop service model to the next level. When you partner with a one-stop golf bag manufacturer, you gain a more reliable approach to quality control. Instead of juggling multiple vendors and hoping for consistent standards, everything is managed under one roof, ensuring a seamless and consistent experience.

Quality Control Across All Production Stages

A reliable one-stop provider enforces strict quality checks at every step of production. From material selection to the final inspection, every stage is closely monitored. For example, inspections are conducted during cutting, sewing, assembly, and beyond. Suppliers follow certified quality management systems, ensuring the use of durable materials like high-strength nylon or leather, which are resistant to abrasion, waterproof, and tear-proof. Soft linings, such as velvet, are often used to protect your clubs from scratches.

Quality checks also cover critical details like stitching, zippers, material strength, alignment, and symmetry. Durability tests, waterproofing evaluations, and weight distribution assessments ensure that closures and fasteners perform smoothly throughout the bag’s lifespan.

The benefit of having a single vendor manage quality control is clear: uniformity. When you rely on multiple vendors, integration challenges and diluted accountability can arise, making it harder to pinpoint and resolve issues.

Wide Range of Customization Options

One-stop services shine when it comes to customization. They offer much more than just a logo slapped onto a standard bag. You can personalize nearly every aspect – design, size, material, pattern, and more. Whether you’re looking for stand bags, cart bags, Boston bags, travel bags, or caddy bags, the options are nearly endless.

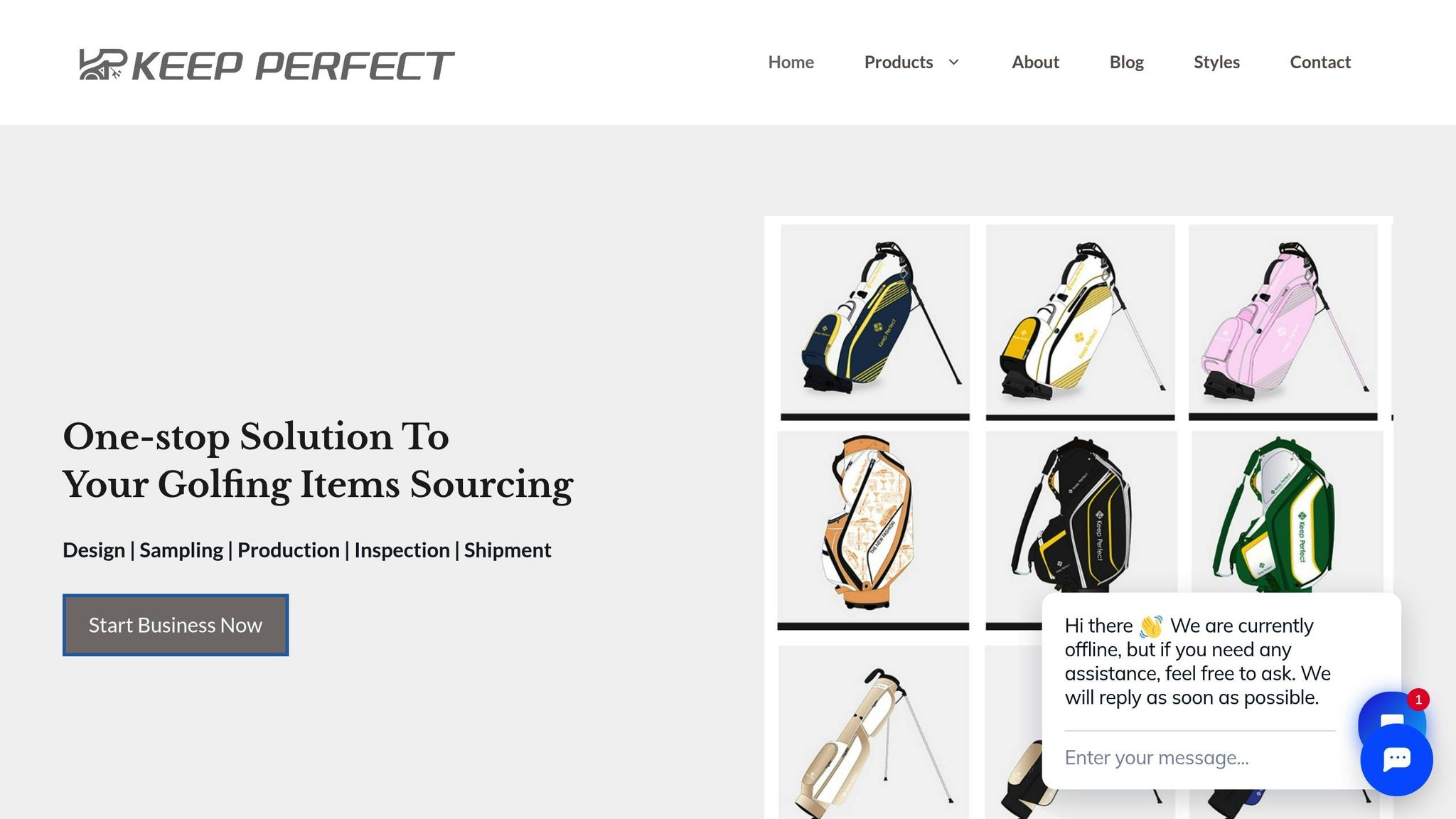

Take Keep Perfect Golf Gear, for example. With over 15 years of experience in custom golf bag manufacturing, they provide full OEM services. Their expertise allows them to offer practical advice tailored to different golfers’ needs and preferences. The customization process involves selecting high-quality materials, coordinating colors for branding, and designing patterns that reflect your personal or corporate style. You can even specify pocket layouts, strap designs, and internal organization features to suit your specific requirements. This level of personalization ties seamlessly into the efficient production process.

Meeting U.S. Market Standards and Preferences

American golfers often have unique preferences for their gear, and a skilled one-stop provider knows how to meet those expectations. For instance, U.S. customers expect dimensions and weight specifications in imperial units, making it easier to understand what they’re buying. The materials and construction methods are designed to handle the diverse conditions across the country, from Florida’s humid summers to Arizona’s dry heat.

Additionally, U.S. business standards are upheld with clear pricing in U.S. dollars, adherence to timelines, and responsive customer service during standard business hours. This approach ensures consistent quality without the hassle of managing multiple supplier relationships.

"With a single point of contact, managing the outsourcing relationship becomes more straightforward. There is no need to juggle multiple contracts, communications, and performance metrics, leading to smoother coordination and less administrative burden." – Sana Masood, Author

Custom Solutions for Golfers and Businesses

When it comes to golf bag design and manufacturing, some providers specialize in creating tailored solutions for both individual golfers and businesses. Whether you’re a weekend player looking for a personal touch or a company interested in branded merchandise, these services offer the flexibility to meet your specific needs. This approach caters to the diverse demands of recreational golfers and professional organizations alike.

Custom Options for Individual Golfers

For individual golfers, customization options are extensive, allowing you to design a bag that perfectly reflects your style and meets your practical needs on the course. You can select from a variety of bag models, color schemes, material textures, logos, and embroidery options. Pricing often depends on the order size. For instance, you can order just a few custom pieces or opt for larger production runs, which typically include volume discounts and additional perks, as noted in customer reviews.

Business and Team Solutions

Custom golf bags are more than just gear for businesses – they double as powerful marketing tools. Companies, tournaments, schools, and golf teams use these bags to promote their brand, turning them into "walking billboards" on the course. Customization options include unique colors, logos, and features that align with your brand’s identity. As Aris Lee, a prominent golf bag manufacturer, puts it:

"Offering customization aligns your brand with clients seeking exclusivity, giving them an experience that standard options can’t match".

Businesses also benefit from cost savings, with volume discounts ranging from 30% to 50% off retail prices for orders exceeding 50 pieces. Some providers even accommodate smaller minimum orders of 100 pieces. Below is an example of pricing for customization options:

| Customization Option | Heat Transfer Price | Embroidery Price |

|---|---|---|

| Name Only | $35 | $50 |

| Logo Only | $35 | Not specified |

| Name & Logo | $60 | Not specified |

For logos, businesses can choose between heat transfer, known for its durability and affordability, and embroidery, which offers a more premium and traditional look. Providers support a range of file formats, such as high-resolution PNG, JPEG, AI, EPS, or PDF files with transparent backgrounds, ensuring high-quality logo results.

Extra Services for U.S. Clients

In addition to customization, U.S. clients enjoy localized services tailored to their market. In 2023, the U.S. golf bag market generated approximately $630.4 million in revenue, with North America accounting for 50.8% of the global market. Many providers offer added conveniences like storage, warehousing, and delivery to meet local demands.

"Sourcing locally can be a significant selling point for golf retailers and pro shops looking to attract eco-conscious customers. Opting for American-made bags reduces the carbon footprint associated with long-distance shipping and promotes a more sustainable manufacturing process."

– Fredrick Ward, Luxury Leather Golf Bags Manufacturer and Distributor

Choosing American suppliers also comes with benefits like quicker shipping, support for local economies, and fewer risks tied to international supply chains. Quality remains a top priority, with manufacturers using premium materials such as leather, high-denier nylon, and durable synthetics to handle the challenges of U.S. golf courses and weather conditions.

Providers like Keep Perfect Golf Gear exemplify this all-encompassing approach, offering services that include warehousing, storage, design, sampling, production, inspection, packaging, and global delivery.

Conclusion: Why Choose a Complete Service Partner

Key Benefits: Efficiency, Cost, and Quality

The golf bag market is on the rise, with projections estimating it will hit $2.32 billion by 2030, growing at an impressive 9.5% annual rate. This growth presents both opportunities and challenges for golfers and businesses looking for custom solutions. Partnering with a one-stop service provider helps meet these challenges by delivering three essential advantages.

Efficiency comes from a streamlined process that eliminates the hassle of juggling multiple vendors. A single provider simplifies everything – reducing miscommunication, cutting down on delays, and ensuring faster project completion.

Cost savings are another major benefit. By working with a single-source production partner, businesses can avoid the markup fees often added by middlemen. Elena Huang, an expert in outdoor and sport bags manufacturing, highlights the importance of sourcing high-quality materials:

"Sourcing golf bags made in the USA, quality and craftsmanship should be your primary focus. Partner with best golf bag manufacturers who specialize in premium materials such as leather, high-denier nylon, or other durable synthetics that can withstand wear and tear, especially for high-performance golf courses or avid golfers".

While American-made golf bags might come with a 25-50% price premium compared to imported ones, they offer better long-term value. Imported bags generally last 3-4 years with regular use, whereas U.S.-made bags can endure 7-10 years under the same conditions. This durability, combined with direct oversight of production, ensures superior quality and fewer defects – a key advantage of having one provider manage the entire process.

Why Keep Perfect Golf Gear Works for U.S. Clients

Keep Perfect Golf Gear exemplifies the benefits of a centralized production and quality control system. With a strong presence in the U.S. market, they understand the specific needs of American golfers and businesses, offering services tailored to this audience.

Their comprehensive offerings cover warehousing, storage, design, sampling, production, inspection, packaging, and global delivery. This all-in-one approach eliminates logistical headaches, making custom golf bag projects seamless from start to finish.

Sustainability is also becoming a priority for many American consumers. Fredrick Ward, a manufacturer and distributor of luxury leather golf bags, emphasizes this shift:

"Sourcing locally can be a significant selling point for golf retailers and pro shops looking to attract eco-conscious customers. Opting for American-made bags reduces the carbon footprint associated with long-distance shipping and promotes a more sustainable manufacturing process".

Whether for businesses or individual golfers, combining high-quality materials, customized options, and sustainable practices offers value that goes far beyond the initial purchase. From personalized logos and colors to durable materials and advanced features, the one-stop approach ensures a consistent standard of excellence throughout the process.

With trends like hybrid bags, lightweight stand bags, and tech-enhanced cart bags expected to dominate by 2025, manufacturers need to keep pace with evolving demands. A complete service partner like Keep Perfect Golf Gear delivers the flexibility to adapt to these changes while maintaining the craftsmanship and reliability American golfers expect. This approach ensures top performance in every aspect, making it a smart choice for meeting the needs of today’s market.

FAQs

How does working with a one-stop service for golf bag design and manufacturing enhance quality control?

Partnering with a single, all-in-one service provider guarantees consistent quality across the entire design and manufacturing process. When everything is managed in one place, the chances of miscommunication or mistakes – often common when juggling multiple vendors – are significantly reduced.

This integrated approach offers direct control at every step, from choosing materials to the final stages of production. It ensures uniform standards are upheld, reduces the likelihood of defects, and consistently delivers a finished product that aligns with your expectations.

What customization options can golfers and businesses expect from a one-stop golf bag manufacturer?

When working with a one-stop golf bag manufacturer, both golfers and businesses can take advantage of an array of customization options designed to meet their specific needs. These options include:

- Color selection: Choose shades that align with your personal taste or represent your brand’s identity.

- Logo placement and embroidery: Add a personal touch or showcase corporate branding with customized logos.

- Material choices: Pick from a variety of materials that balance durability, performance, and appearance.

- Specialized design features: Incorporate unique elements tailored to your preferences or business goals.

With these choices, it’s easy to design golf bags that combine practicality with a touch of personality or brand flair.

How can working with a one-stop service simplify operations and reduce costs for businesses?

Partnering with a single service provider that handles everything can make running a business much easier and more cost-effective. When design, manufacturing, and supply chain management are all managed under one roof, you no longer have to juggle multiple vendors. This not only saves time but also cuts down on the headaches of coordinating between different teams.

Another big perk? These providers often offer bulk pricing and have more efficient production systems in place. That means you can lower your costs without sacrificing quality. Plus, with faster turnaround times and a smoother workflow, your business can stay focused on what really matters – growing and keeping your customers happy.