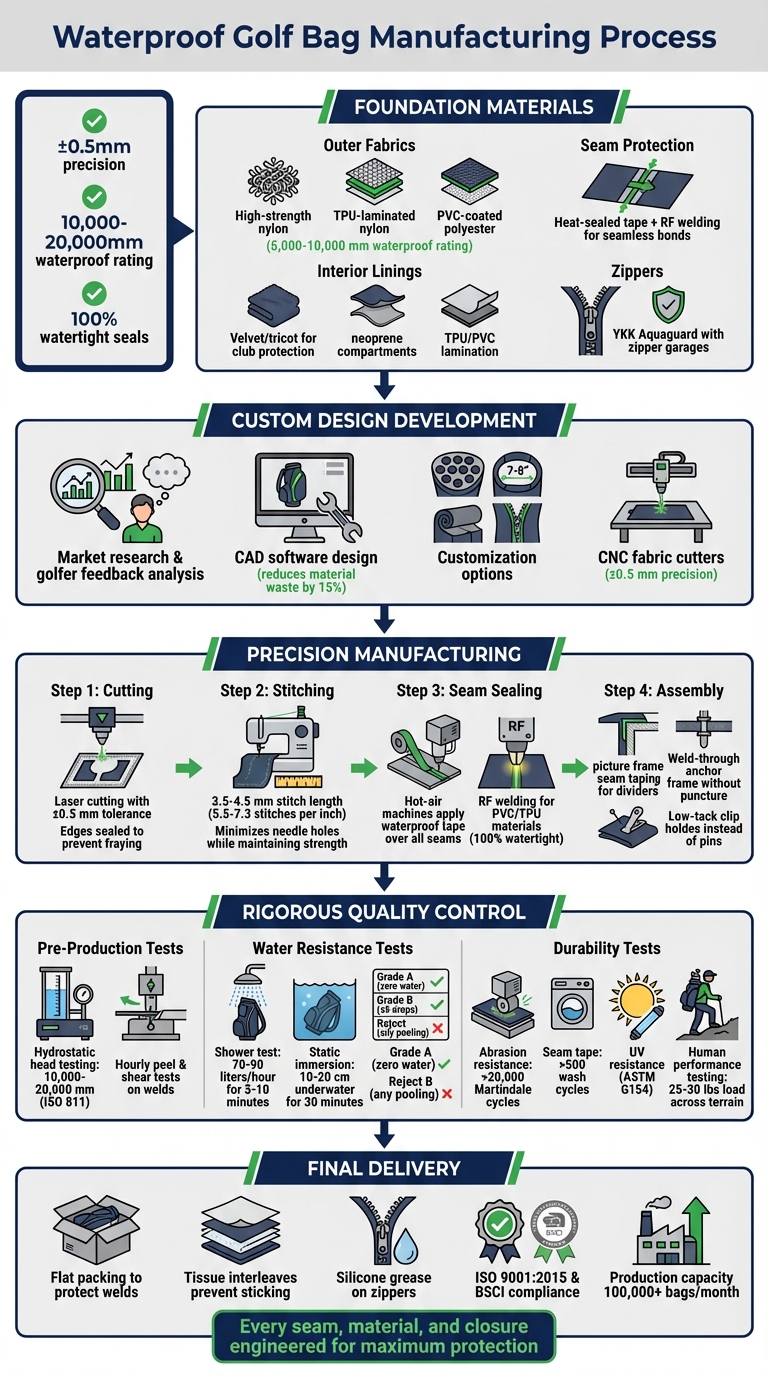

Golfers need waterproof bags to protect their gear from rain and moisture, which can damage clubs, grips, and accessories. Waterproof golf bags are crafted using advanced materials like TPU-laminated nylon and techniques such as RF welding and seam sealing to ensure durability and water resistance. Key features include waterproof zippers, reinforced seams, and protective linings, all designed to keep contents dry.

Key Takeaways:

- Materials: High-strength nylon, TPU-laminated fabrics, and PVC coatings provide water resistance and durability.

- Seam Techniques: Heat-sealed tape and RF welding prevent leaks through stitching.

- Zippers: YKK Aquaguard zippers with garages block water entry.

- Testing: Bags undergo air leak, shower, and immersion tests to ensure performance.

- Customization: Options include divider configurations, branding, and color choices.

Manufacturers like Keep Perfect Golf focus on precision and rigorous quality control to deliver reliable waterproof golf bags that perform in any weather.

Waterproof Golf Bag Manufacturing Process: From Materials to Quality Testing

Materials Used in Waterproof Golf Bags

Waterproof Fabrics and Outer Materials

The outer shell of a golf bag does more than just look good – it’s the first line of defense against rain and wear. Manufacturers often use high-strength nylon for durability, polyester for its long-lasting color vibrancy, and synthetic leather (like PU or vegan leather) in premium models for a sleek finish that’s easy to clean after muddy rounds.

To ensure true water resistance, these materials are treated with specialized coatings. A basic Durable Water Repellent (DWR) coating makes water bead and roll off, but it won’t hold up during a heavy downpour. For more demanding conditions, TPU-laminated nylon is a popular choice because it stays flexible even in freezing temperatures. On the budget-friendly side, PVC-coated polyester offers solid waterproofing (with ratings between 5,000–10,000 mm) and can withstand plenty of abrasions.

"A waterproof bag is far more than a fashion statement. It’s a functional engineering product designed to keep contents completely dry, even in extreme conditions like heavy downpours or full submersion." – Eric, Szoneier

Seam Sealing Methods

Even the toughest waterproof fabric can fail if water sneaks in through the seams. That’s why manufacturers use heat-sealed waterproof tape on the inside of stitched seams. This tape forms a barrier, preventing water from seeping through the tiny holes left by stitching.

For even stronger protection, some brands use RF welding, a technique that melts thermoplastic materials together to create a seamless, waterproof bond. This method is a hallmark of brands like Ortlieb, known for their expertise in waterproof gear.

"Unlike a stitched seam, a welded seam is inherently waterproof. Stitched seams need to be taped to prevent water from entering through the holes from stitching." – Apidura

When choosing a waterproof golf bag, take a look inside. If the seams are taped or welded, you’re in good hands. Exposed stitching, on the other hand, can eventually let water in, no matter how high-quality the outer material is.

Interior Linings That Resist Water

The interior of a waterproof golf bag is just as important as the exterior. Soft materials like velvet or tricot are often used to protect clubs, while neoprene compartments provide extra benefits like waterproofing, impact cushioning, and even insulation.

Some bags take it a step further with technical linings that feature microporous structures. These linings allow moisture vapor to escape while keeping water droplets out, which helps prevent that sticky, damp feeling inside the bag. This design also protects leather grips from damage caused by prolonged exposure to moisture. Additionally, TPU or PVC lamination on the reverse side of the lining creates an extra layer of protection, keeping the interior dry even when the outer shell is soaked.

These carefully chosen materials and techniques are what make waterproof golf bags both functional and durable, ready to handle the toughest conditions on the course.

Design and Prototype Development

Understanding What Golfers Need

Before diving into prototyping, manufacturers take a step back to understand exactly what golfers need. They consider the specific scenarios in which these bags will be used – whether it’s light rain on the golf course or full-on immersion in water.

To get this right, factories rely on data collected through market surveys and feedback from professional players. Take this for instance: a 2024 outdoor retail survey revealed that waterproof backpacks made up 42% of all waterproof bag sales in urban markets. This shows that modern golfers often look for bags that can double as everyday gear. Insights like these influence design choices – pocket placement, strap comfort, and even whether to include extras like laptop compartments or USB charging ports.

"A waterproof bag isn’t just ‘a bag that doesn’t leak’ – it’s a carefully engineered solution where every material, seam, and closure is chosen for maximum protection." – Szoneier

By identifying these preferences, manufacturers can fine-tune features to meet the demands of today’s golfers.

Custom Options and Features

Customization is where things get interesting. Golfers can pick from a range of features to suit their needs. For example, they can choose bag openings that are 7 or 8 inches wide, depending on how much space they want. Pocket options vary too – some bags stick to a single pocket for essentials, while others offer dual-pocket designs that can hold rain gear and drinks.

When it comes to closures, there are trade-offs. Roll-top seals are cost-effective and offer excellent water protection, while YKK Aquaguard waterproof zippers make accessing your gear quicker. High-end bags even feature magnetic seal flaps for one-handed use – an option trusted by PGA Tour players. For instance, the Tour Rain Hood by Seaforth uses four strong magnets to keep things secure.

Structural upgrades include carbon fiber battens for lightweight durability and molded anchor points for straps, which avoid the needle holes that could compromise waterproofing. Branding options are equally versatile, offering embroidery, HF-embossing, and color-coded materials that range from treated canvas to synthetic leather for a sleek, modern look.

Building and Testing Sample Bags

Once the design is finalized, it’s time to bring it to life through prototyping and testing. This process starts with creating visual and functional models, eventually leading to polished samples that are ready for mass production.

Advanced tools like CAD software allow engineers to review designs digitally, cutting down material waste by 15%. In August 2025, Szoneier shared details about their process, which includes using CNC fabric cutters with a precision of ±0.5 mm. They also use advanced joining techniques to ensure waterproofing, along with 3-layer seam tape that can handle over 500 wash cycles without peeling.

Testing is rigorous. Factories use air leak tests, where bags are inflated to 3–5 kPa and sprayed with soapy water to detect tiny leaks. Shower tests simulate rain by dousing bags for 5–10 minutes with 70–90 liters of water per hour. For heavy-duty bags, there’s the static immersion test, where bags are submerged 10–20 cm underwater for 30 minutes to ensure no water seeps in.

"The prototyping stage of your project is your opportunity to get things wrong without investing too much time or money – and to fix problems before they have potentially expensive consequences." – Essentra Components

Manufacturing Steps for Waterproof Golf Bags

Cutting and Stitching Techniques

The production of waterproof golf bags begins with precise planning. Manufacturers use CAD nesting software to create cutting patterns that minimize fabric waste while ensuring the grain aligns for optimal strength. This digital approach not only boosts efficiency but also reduces material waste by up to 15% in large-scale production when paired with CNC fabric cutters.

For cutting, laser technology is the go-to method. It offers remarkable accuracy, with a tolerance of ±0.5 mm, and simultaneously seals fabric edges to prevent fraying. Once the panels are cut, the stitching process begins, adhering to strict guidelines. For waterproof designs, a stitch length of 3.5–4.5 mm (roughly 5.5–7.3 stitches per inch) is used. This density strikes a balance: it minimizes needle holes while maintaining the bag’s structural integrity.

The magic happens after stitching. Hot-air machines apply waterproof seam tape over every seam, sealing needle holes to block water. For materials like PVC or TPU, manufacturers skip stitching altogether, opting for RF welding or hot-air welding instead. These methods create completely watertight bonds.

| Feature | Standard Stitching | Reinforced & Sealed Stitching |

|---|---|---|

| Water Resistance | Risk of leaks through needle holes | Taped or welded seams block 100% of water |

| Durability | Edges prone to fraying | Laser-cut edges and durable threads prevent tearing |

| Stitch Density | Variable | Optimized (5.5–6.5 SPI) for strength and fewer punctures |

| Longevity | Moisture can degrade material | Sealed seams stop internal wicking and mold growth |

"A waterproof bag will have taped or sealed seams… If you see a thin strip of rubbery-looking tape covering the stitching, the manufacturer has sealed that entry point for water." – Spencer Lanoue, Founder, Caddie AI

With the panels sealed and ready, manufacturers move on to assembling dividers and pockets to ensure the bag’s overall waterproof performance.

Installing Dividers and Pockets

Once the panels are sealed, the next step is integrating waterproof dividers and pockets. Manufacturers use a technique known as "picture frame" seam taping when stitching these components into place. This involves placing an internal patch behind the stitched area and applying seam tape around the perimeter. This method ensures needle perforations are isolated, keeping the bag’s interior completely sealed.

For zippers, water-resistant options like YKK Aquaguard are installed on raised welts – seams elevated to keep the zipper track away from standing water. At the ends of zipper tracks, "zipper garages" are added. These protective covers prevent water from sneaking through the zipper’s end-stop. Before any welding or taping, the bond areas are cleaned with 70% or higher isopropyl alcohol to remove oils and dust, ensuring a reliable seal.

For high-end bags, RF welding is used to handle the complex 3D joins where dividers meet the bag shell. This process fuses PVC or TPU coatings through the fabric layers without creating holes, resulting in a permanent, leak-proof bond often stronger than the fabric itself.

Adding Frames with Lightweight Materials

After securing the internal compartments, manufacturers focus on reinforcing the bag’s structure with lightweight frames. Materials like carbon fiber and lightweight alloys are preferred for their strength and minimal weight. However, attaching these frames presents a challenge – puncturing the waterproof membrane must be avoided.

To solve this, manufacturers use weld-through anchors or laminated tabs, which secure frames and hardware without creating needle holes in high-stress areas. If stitching is unavoidable, the picture frame seam taping method is applied to maintain waterproofing.

During assembly, workers rely on low-tack clips instead of pins to hold panels in place. Pins can puncture the fabric, compromising its waterproof properties, while clips avoid this issue entirely. Additionally, all corners of pockets and panels are designed with a minimum radius of 6 mm to prevent stress-tears and seal failures over time. Once assembly is complete, each bag undergoes air pressure testing at 3–5 kPa. Workers spray soapy water on seams and watch for bubbles, which reveal even the smallest leaks.

This meticulous attention to detail, from frame installation to final testing, highlights the craftsmanship behind premium waterproof golf bags.

Quality Control and Testing Methods

Inspection at Multiple Production Stages

The precision used in cutting and seam sealing isn’t just for show – it sets the stage for thorough quality control at every production step. Manufacturers integrate checks throughout the process to ensure every bag meets strict standards. Before any cutting begins, the fabrics are subjected to hydrostatic head testing based on the ISO 811 standard. This confirms their waterproof ratings, which typically range between 10,000 mm and 20,000 mm. During the cutting phase, inspectors ensure that CNC or laser equipment maintains an accuracy of ±0.5 mm, which is vital for consistent weld allowances.

As the welding process moves forward, workers conduct peel and shear tests on sample strips hourly. These tests measure the force required to break the bond, helping detect any shifts in machine settings before defective bags are produced.

Visual inspections also play a critical role. Inspectors identify potential issues like "tunneling" (air tracks visible in welds), "fish-mouths" (gaps in overlapping panels), and "cold welds" (areas of incomplete fusion that appear dull instead of glossy). They also check that zipper garages are properly installed and lubricated to ensure smooth operation.

Once these inspections are complete, the bags undergo rigorous water and stress testing to confirm their durability and waterproofing capabilities.

Water Resistance and Stress Testing

After assembly, each bag faces a series of water resistance tests to ensure it can handle wet conditions. These include a shower simulation, where the bag is exposed to 70–90 liters of water per hour for 5–10 minutes, and static immersion, where it is submerged 10–20 cm underwater for 30 minutes.

The results are graded with no room for leniency. A Grade A rating signifies a flawless pass with zero water penetration. A Grade B rating allows up to five localized drops but is still considered acceptable. However, any pooled water or visible wicking leads to immediate rejection.

| Test Type | Standard | Pass Criteria |

|---|---|---|

| Hydrostatic Head | ISO 811 | ≥ Target mm rating (10,000–20,000 mm) |

| Seam Leak Test | ASTM D751 | No leaks after 5 minutes |

| UV Resistance | ASTM G154 | No significant fading or cracking |

| Abrasion Resistance | Martindale | > 20,000 cycles without coating delamination |

Stress tests are just as demanding. Straps and frames are subjected to repeated loading cycles to simulate real-world use. Abrasion resistance is tested using the Martindale method, requiring coatings to endure over 20,000 cycles without peeling or delaminating. Additionally, professional-grade seam tape must survive more than 500 wash cycles without failure.

Testing Weight Balance and Comfort

Beyond water resistance and durability, manufacturers also evaluate how the bag performs in real-world scenarios. This includes human performance testing, where actual golfers carry fully loaded bags across different terrains. According to Gore-Tex:

"Lab tests are great. But only people can judge how products feel, work and wear in different environments and activities. That’s why human testing is crucial" – Gore-Tex

For these tests, bags are packed with standardized loads – typically 14 clubs and accessories weighing 25–30 lbs. – to assess how weight is distributed across shoulder straps and the back panel. Testers also time how quickly they can access clubs while walking, and they evaluate whether the bag shifts, pulls to one side, or causes discomfort during extended use.

These real-world trials uncover subtle issues that lab tests might miss, such as pressure points that develop after a full round or strap adjustments that slip under heavy loads. By addressing these details, manufacturers ensure that waterproof golf bags not only protect your gear but also deliver comfort and reliability, keeping players confident even in the rain.

sbb-itb-4fa7e8b

Packaging and Custom Order Fulfillment

Protective Packaging for Transport

Once a product passes quality checks, it’s carefully packaged to protect its integrity during transport. Waterproof bags, for example, are laid flat instead of folded to avoid creases that could damage heat-welded seams or weaken coated fabrics. Tissue paper is placed between coated layers to prevent sticking and scratches, ensuring the product stays in pristine condition.

Waterproof zippers, such as TIZIP or Aquaseal, require special care. Bending or creasing these zippers can compromise their airtight seals, so they are handled with extra caution. Before storage or international shipping, the zippers are treated with silicone-safe grease to prevent any seizing or damage over time.

| Packaging Element | Purpose | Recommended Method |

|---|---|---|

| Internal Padding | Preserve shape | Use tissue interleaves or air pillows |

| Seam Protection | Avoid weld damage | Pack flat, avoiding sharp folds |

| Zipper Care | Maintain airtight seals | Keep straight; apply silicone grease |

| Documentation | Product care instructions | Include care leaflets and UV advice |

Care leaflets are included with every product, offering guidance on rolling, zipper maintenance, and proper UV storage. Products are sealed in poly bags and packed into durable custom boxes designed to withstand varying climates during international shipping.

This meticulous packaging process ensures that products arrive in excellent condition, reflecting the high standards of Keep Perfect Golf. From protective packaging to custom manufacturing, every step is designed to deliver premium waterproof bags.

Custom Manufacturing Services from Keep Perfect Golf

Beyond packaging, Keep Perfect Golf offers highly customized manufacturing services to meet diverse client needs. Their fulfillment process includes five key steps: consultation and requirements gathering, design and prototyping, production planning, manufacturing with quality checks, and final packaging and shipping. Operating out of a 20,000-square-meter (about 215,000 square feet) facility, the company employs over 300 skilled workers and produces more than 100,000 golf bags per month.

Customization options are extensive. Clients can choose materials like nylon, polyester, canvas, or leather. They can also select custom colors, adjust club divider configurations (ranging from 4-way to 14-way setups), and add personalized branding through embroidery, screen printing, or heat transfer. For businesses, private label services ensure products are retail-ready, offering custom hangtags, labels, barcodes, UPC labeling, and warranty information tailored to the brand.

| Order Tier | Minimum Order Quantity (MOQ) | Lead Time | Customization Level |

|---|---|---|---|

| Standard | 50–100 units per style | 30–45 days | Standard options |

| Medium | 100–500 units per style | 45–60 days | Enhanced options + Free sample |

| Large | 500+ units per style | Priority scheduling | Full customization capabilities |

Products are shipped globally through trusted logistics partners, adhering to ISO 9001:2015 standards and BSCI audit compliance. For brands committed to sustainability, custom orders can also include eco-friendly materials and recycled fabrics.

How Golf Bags Are Made? 🏅 Inside a Professional Golf Bag Factory Tour

Conclusion

Creating a top-notch waterproof golf bag involves much more than simply adding a water-resistant layer. As Eric from Szoneier puts it, "A waterproof bag isn’t just ‘a bag that doesn’t leak’ – it’s a carefully engineered solution where every material, seam, and closure is chosen for maximum protection". This means using materials like TPU-laminated nylon with hydrostatic head ratings of 10,000–20,000 mm and employing RF welding techniques to eliminate needle holes – every detail is meticulously planned to keep your gear safe from water.

Each step of the manufacturing process is designed with reliability in mind. Advanced production techniques and thorough quality checks ensure the bags can handle real-world demands, from sudden rainstorms to accidental submersion. These efforts make sure that every bag performs under tough conditions.

Working with a seasoned manufacturer like Keep Perfect Golf brings another layer of expertise. With over 300 skilled workers, a 215,000-square-foot facility, and the ability to produce more than 100,000 golf bags per month, Keep Perfect Golf offers a combination of cutting-edge material science, specialized equipment, and rigorous quality control. Their ISO 9001:2015 certification and BSCI compliance further highlight their commitment to excellence. Whether you’re ordering 50 standard bags or 500+ custom-branded units, their technical know-how ensures your investment results in a waterproof bag that stands the test of time. This level of craftsmanship turns a standard bag into a reliable, waterproof solution.

FAQs

What materials are used to make golf bags completely waterproof?

Waterproof golf bags are made from tough nylon or polyester fabrics treated with thermoplastic polyurethane (TPU) or polyurethane (PU) coatings. These fabrics are often layered into a three-layer design to improve water resistance. To keep water out entirely, the seams are sealed using RF welding technology, which blocks any potential leaks. This smart mix of materials and methods keeps the bags lightweight, sturdy, and fully waterproof – even during heavy downpours.

How do golf bag manufacturers make sure the seams are waterproof?

Manufacturers rely on specialized methods like heat-welding or seam-taping to keep seams waterproof. These processes seal the stitched edges, forming a watertight barrier. Along with these techniques, they often use durable waterproof thread or seam tape that bonds fabric layers tightly, ensuring no water can sneak through. These steps are key to ensuring the product holds up and performs well, no matter the weather.

How do manufacturers ensure golf bags are truly waterproof?

When it comes to making golf bags waterproof, manufacturers put them through a variety of intense testing procedures. This includes lab tests on the materials and membranes to ensure they repel water effectively. Beyond the lab, bags face real-world trials in different weather conditions to see how they hold up. Simulated use tests are also performed to mimic the challenges a bag might encounter during regular play.

Some of the most demanding tests involve full submersion in water and high-pressure sprays aimed at vulnerable spots like seams, zippers, and closures. These steps help pinpoint any weak areas where leaks could occur.

By going through these rigorous evaluations, manufacturers ensure the bags can handle heavy rain and damp conditions, keeping golfers’ gear safe and dry out on the course.