Ensuring quality in custom golf bag manufacturing requires two main approaches: supplier audits and in-house quality checks. Each serves a distinct purpose:

- Supplier Audits: Assess a supplier’s ability to meet production needs before placing an order. This includes verifying equipment, materials, certifications, and overall factory capabilities. It’s a preventive measure to avoid risks like unreliable vendors or production delays.

- In-House Quality Checks: Focus on inspecting products during or after production. Teams ensure finished goods match standards, addressing issues like seam strength or waterproofing before shipping.

Key Differences:

- Supplier audits evaluate long-term reliability and factory capabilities.

- In-house checks ensure immediate product quality and fix defects in real time.

When to Use Each:

- Use supplier audits for vendor qualification and risk assessment.

- Use in-house checks during production to maintain quality.

For the best results, combine both methods. Start with audits to select reliable partners, then use in-house checks to monitor production quality.

Benefits of Supplier Audits

Better Visibility into Supplier Performance

Supplier audits provide an up-close look at factory operations that remote evaluations simply can’t match. As Matthew Milasius from InTouch Quality puts it, "It’s often difficult, if not impossible, to accurately evaluate suppliers remotely". By conducting on-site audits, you can confirm whether a factory’s actual capabilities align with its claims.

Take custom golf bag production, for example. An audit can verify if the supplier has the right machinery for handling unique fabrics, ensure their testing equipment is properly calibrated for durability checks, and confirm that storage conditions meet the standards needed to prevent mold or material degradation. Auditors also examine maintenance logs and calibration records to ensure consistency across production runs. This hands-on approach not only confirms a factory’s ability to deliver but also simplifies the process of pre-qualifying potential suppliers.

Pre-Qualification of Vendors

Audits serve as a reliable screening tool, helping you weed out unreliable vendors before you commit to an order or deposit. They verify critical details such as business licenses, export permits, and ISO 9001 certifications, ensuring you’re dealing with a legitimate manufacturer rather than a front for unverified sub-suppliers. Pro QC International emphasizes that "a supplier quality audit provides purchasing managers and quality personnel enhanced data and transparency on the best practices at each factory or supplier".

For OEM/ODM golf bag production at Keep Perfect Golf Gear, this means you can confidently select factories with the technical expertise, financial stability, and quality management systems needed to handle custom logo placement, material selection, and intricate pattern designs. By establishing vendor credibility early, you’re also better positioned to identify potential issues before full-scale production begins.

Early Detection of Process Problems

Audits are a proactive way to catch inefficiencies and compliance issues before they escalate into costly production problems. By reviewing incoming quality control procedures, auditors can confirm whether the factory has clear standards for accepting or rejecting raw materials like fabrics and hardware. They also check for an independent quality control team, ensuring an unbiased evaluation process.

Addressing these practices early helps prevent quality issues from impacting your entire order. For instance, in golf bag production, where waterproof coatings, precise stitching, and functional stand mechanisms are critical, audits can uncover potential problems in training records or workstation procedures that might lead to delays or defects. Identifying and resolving these issues upfront ensures consistent quality across production runs, safeguarding the high standards required for custom OEM/ODM golf bags.

SBB-ITB-4FA7E8B

Challenges of Supplier Audits

High Costs and Time Requirements

Supplier audits can quickly rack up costs, especially for smaller production budgets. Labor expenses alone can account for one to two man-days per audit, and when you add travel costs – especially for remote factory locations – the financial strain grows. This is even more pronounced when dealing with multiple SKUs or urgent orders that require quick evaluations.

In the case of custom golf bag production, costs can climb even higher. Factors like the number of SKUs, the scope of functional testing, and specific sampling requirements all add to the bill. If audits are scheduled late or need a fast turnaround, additional surcharges may apply. While these expenses serve as a safeguard – helping prevent the much larger costs tied to defective goods, rework, customs delays, or recalls – they remain a significant initial investment. To make the most of these audits, consider grouping inspections for multiple products or batches and booking them early to sidestep urgency fees.

These logistical and financial hurdles make supplier transparency all the more critical, which brings us to the next challenge: cooperation.

Dependency on Supplier Cooperation

Supplier audits hinge on the willingness of suppliers to cooperate. A supplier’s resistance can be a major warning sign, potentially signaling an attempt to hide issues like poor working conditions or subpar quality. George Huang from InTouch Quality emphasizes:

Resistance from the supplier is a red flag. It often indicates the supplier may be trying to hide something, like substandard working conditions or poor quality.

Sometimes, suppliers claim they are "too busy" for inspections, a tactic often used to avoid scrutiny.

Another issue arises when relying solely on information provided by the supplier. Factory QC staff, who work directly for the facility, may downplay or fail to report defects to avoid costs tied to rework or delays. These staff members rarely provide importers with the detailed reports – including photos and test results – necessary for full transparency. Additionally, some suppliers may act as a "front" for other facilities, masking the actual source of production. To protect your interests, ensure on-site verification of business licenses, export permits, and ISO 9001 certifications. It’s also wise to confirm that the supplier has an independent QC team, easily identifiable by distinct uniforms or separate reporting structures.

Without full transparency, maintaining the quality standards expected for custom golf bags becomes a challenge.

Limited Focus on Final Product Assembly

Audits often fall short when it comes to assessing post-production processes. They don’t guarantee the quality of every unit in a mass production run, particularly when the final assembly happens in-house. George Huang points out:

A factory owner’s desire to ship out POs quickly and continue generating revenue often overshadows QC staff’s duty to inspect your product.

Another limitation stems from the fact that audits only provide a snapshot of production. Samples used during audits are often created by specialized R&D teams, not pulled directly from the regular production line. This means the audit may not accurately represent the quality of the full production run. For custom golf bags, which often involve a mix of materials and intricate assembly processes, this can result in overlooked defects in packaging, labeling, or other final-stage issues. To address this, it’s a good idea to conduct pre-shipment inspections once production reaches 80% completion. Pair this with in-line inspections at the 20% mark to catch problems early and prevent them from affecting the entire order.

Benefits of In-House Quality Checks

Direct Control Over Final Product Quality

In-house quality checks give manufacturers immediate oversight to address product defects as they arise. Internal quality control (QC) teams can halt production the moment they detect a serious issue, preventing defects from spreading across an entire batch. This is especially crucial in processes like logo customization and patterning, where even slight misalignments can ruin the final product.

These teams ensure every item meets the agreed-upon "Golden Sample" standards, covering details like stitching, edge paint, and balance. For instance, at Keep Perfect Golf, each custom golf cart bag or stand bag is inspected to match the exact specifications set during the design phase. Any defects are corrected in real-time, ensuring the final product aligns with customer expectations.

Building Internal Quality Standards

In-house quality checks do more than catch defects – they help establish and maintain high-quality standards over time. When quality control is handled internally, it fosters a sense of accountability within the organization. As Inspectorio highlights:

Build a culture of quality across your organization, creating high standards of accountability, empowerment, and visibility needed for continuous improvement.

Customizing QC protocols for specific production needs, such as the unique demands of custom golf bag manufacturing, becomes possible with an internal team. Over time, this team develops a deep understanding of materials and stitching techniques, enabling them to predict and prevent common issues.

This expertise grows with each production cycle. Companies using internal digital quality platforms report a 19% reduction in defective unit rates and save 80–90% of the time typically spent on corrective actions by addressing problems at their source. These clear, consistent standards ensure quality remains steady across all teams and shifts.

Integration with One-Stop Production Process

In-house quality checks complement Keep Perfect Golf’s one-stop production model, where every step – from design and sampling to packaging and delivery – happens under one roof. Quality control is integrated into every stage of production. As Zoey Lee, Sales Director at Osgoodway, explains:

QC isn’t just a final inspection; it’s an ongoing commitment that starts from the very first design to the moment the bags leave the factory.

This integrated approach catches defects during material handling, stitching, and assembly, instead of waiting until the final inspection stage. Automated tools like laser cutters and stitching machines further minimize human error, ensuring precise stitching and consistent fabric quality across large orders. By embedding quality checks throughout the production workflow – from selecting materials to inspecting hardware – the process eliminates costly delays and rework caused by late-stage defect detection. This seamless integration reinforces product quality while optimizing efficiency.

Auditing And Supplier Quality Inspections

Challenges of In-House Quality Checks

While in-house quality checks provide direct oversight and integration with production processes, they also come with hurdles that can strain resources and compromise efficiency.

Intensive Resource Demands

Conducting thorough in-house quality checks requires a heavy investment in skilled personnel, time, and specialized equipment. In custom golf bag manufacturing, for example, inspectors need expertise in both textiles – like fabric quality and stitching – and hard goods such as frames and molding. This dual expertise makes hiring and training more complex and expensive.

The process often involves 11 detailed steps, from planning to follow-up, requiring dedicated professionals to meticulously document defects using specific tools. According to Qualityze:

Resource constraints: Limited time, budget, or personnel can hamper audit thoroughness.

Tight shipping deadlines and last-minute delays often force rushed approvals, reducing the thoroughness of inspections. A recent study revealed that 60% of respondents identified supply chain challenges as a major risk factor. These constraints highlight how critical yet resource-intensive in-house quality checks can be, often stretching human and operational capacities to their limits.

Risk of Internal Oversight Bias

One of the biggest challenges for internal quality teams is staying objective when evaluating products made by their own organization. Factory management often prioritizes shipment schedules and revenue goals, which can pressure quality control (QC) staff to pass products that may not meet standards. As InTouch Quality explains:

A factory owner’s desire to ship out POs quickly and continue generating revenue often overshadows QC staff’s duty to inspect your product.

This pressure can lead to overlooked defects or superficial evaluations. In one case, a factory’s internal QC team reported 100% conformity on electronic components, but later testing revealed a 15% failure rate. Independent auditors confirmed that the factory had manipulated testing procedures to approve defective products. Additionally, internal teams often lack the detailed reporting – complete with photos and test results – that third-party auditors typically provide.

These challenges grow even more pronounced as production scales, making consistent quality assurance increasingly difficult.

Difficulty Scaling for High-Volume Orders

As production volumes rise, maintaining consistent quality checks becomes a daunting task. Limited staff, fixed budgets, and manual record-keeping increase the likelihood of errors, especially when managing multiple suppliers or geographically dispersed manufacturing facilities.

Unlike third-party services that offer scalable, fee-based models, in-house quality checks require a permanent investment in personnel and equipment. This rigidity makes it tough to adjust operations for seasonal demand or fluctuating order sizes. For custom golf bag manufacturing, balancing these challenges against the demands of supplier audits becomes a key consideration when deciding on the best quality control approach.

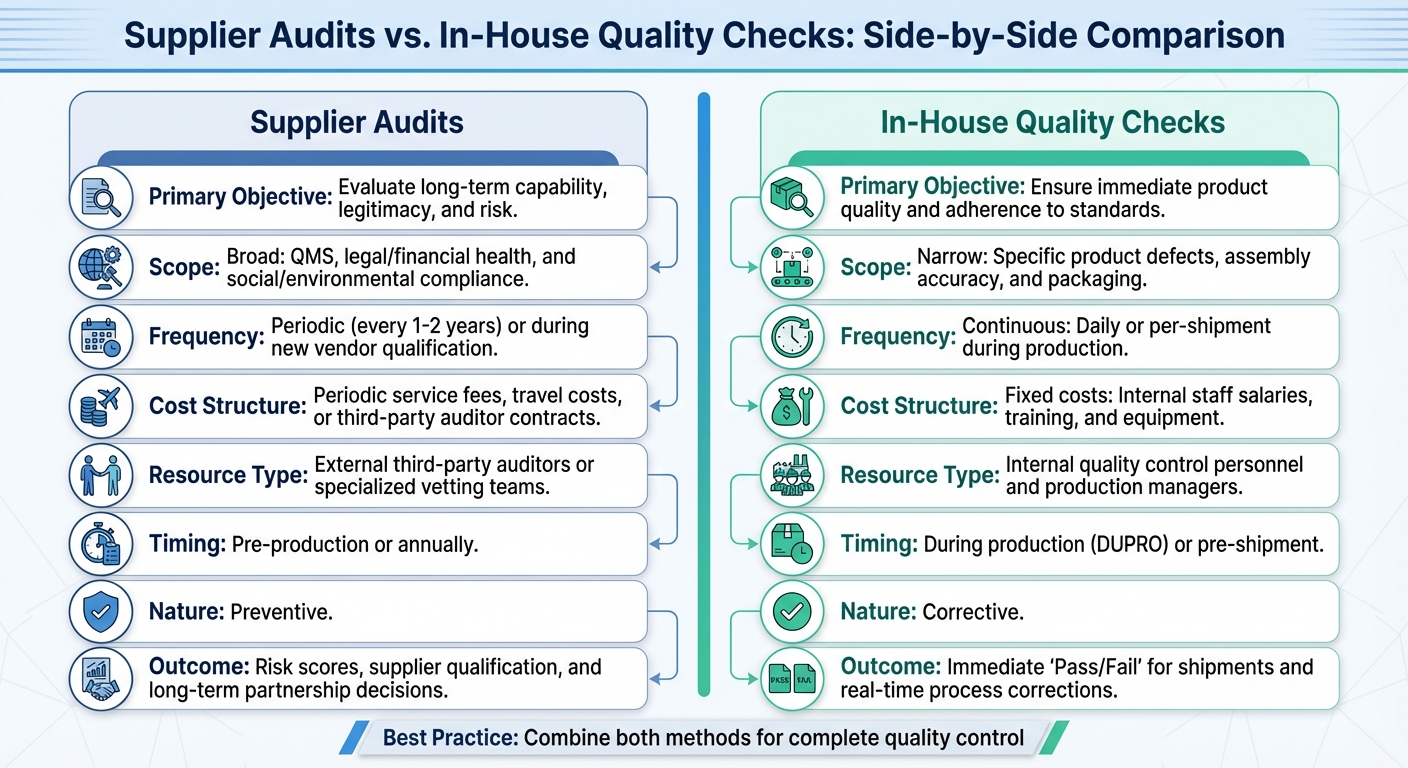

Supplier Audits vs. In-House Quality Checks: Side-by-Side Comparison

Supplier Audits vs In-House Quality Checks Comparison Chart

When deciding between supplier audits and in-house quality checks for custom golf bag manufacturing, it’s essential to understand how these two approaches differ. Both play a critical role in quality assurance, but they focus on different stages and objectives.

Supplier audits take a broader view, evaluating a manufacturer’s Quality Management System (QMS), legal compliance, and production capacity. The goal is to assess long-term reliability and reduce risks. On the other hand, in-house quality checks zoom in on the immediate quality of specific shipments, ensuring products meet standards before they leave the factory. As HQTS explains:

Factory audits give a high-level view of how a factory operates and how they can ensure that high quality products are produced… Whereas an inspection is only about one particular shipment.

Here’s a quick comparison to highlight the differences:

Comparison Table

| Feature | Supplier Audits | In-House Quality Checks |

|---|---|---|

| Primary Objective | Evaluate long-term capability, legitimacy, and risk | Ensure immediate product quality and adherence to standards |

| Scope | Broad: QMS, legal/financial health, and social/environmental compliance | Narrow: Specific product defects, assembly accuracy, and packaging |

| Frequency | Periodic (every 1–2 years) or during new vendor qualification | Continuous: Daily or per-shipment during production |

| Cost Structure | Periodic service fees, travel costs, or third-party auditor contracts | Fixed costs: Internal staff salaries, training, and equipment |

| Resource Type | External third-party auditors or specialized vetting teams | Internal quality control personnel and production managers |

| Timing | Pre-production or annually | During production (DUPRO) or pre-shipment |

| Nature | Preventive | Corrective |

| Outcome | Risk scores, supplier qualification, and long-term partnership decisions | Immediate "Pass/Fail" for shipments and real-time process corrections |

Supplier audits often require an upfront investment, but they can help prevent significant financial losses down the line. For those looking to save on costs, desktop audits offer a less expensive alternative to on-site visits, though they may miss certain details. Matthew Milasius from InTouch Quality highlights the importance of this proactive approach:

Identifying these practices before mass production gives you the foresight to speak with your supplier and limit quality defects before your entire order is affected.

When to Use Supplier Audits, In-House Checks, or Both

Choosing the right quality control method depends on your production stage and specific goals. Each approach serves a unique purpose, and knowing when to use each can help prevent costly errors.

Supplier Audits for Vendor Qualification

Supplier audits are crucial when you’re evaluating new manufacturers. These audits focus on verifying a supplier’s legitimacy, financial stability, and ability to meet your quality requirements. This includes reviewing business licenses, ISO 9001 certifications, and production capacity. As Pro QC International explains:

"A supplier quality audit is a cost-effective way for anyone from one-time buyers to large multi-national companies to assess the legitimacy of a supplier."

For example, if you’re ordering custom golf bags with specific requirements like logo placement, material selection, or detailed patterns, supplier audits ensure that the factory can meet these needs. While audits are essential for initial validation, maintaining quality during production requires additional measures.

In-House Checks for Production Oversight

Once you’ve qualified a supplier, monitoring quality during production becomes key. In-house checks allow your team to oversee the assembly process directly. For custom golf bags with intricate designs or precise logo placements, having on-site personnel ensures real-time issue identification, such as misaligned embroidery or stitching problems. Immediate feedback from internal teams is particularly effective in high-volume production scenarios. For instance, Keep Perfect Golf benefits from in-house oversight throughout the design, sampling, and assembly stages. Typically, companies assign one quality inspector for every 15 to 20 active suppliers.

Combined Approach for Complete Quality Control

For the most thorough quality assurance, combining supplier audits with in-house checks is ideal. Start with supplier audits to verify and qualify factory partners. Then, use in-house teams for ongoing monitoring during production – overseeing materials, assembly, and maintaining direct communication with factory management. To wrap up, bring in an independent third-party inspector for a Pre-Shipment Inspection (PSI) to provide an unbiased final check before your custom golf bags are shipped. This hybrid approach ensures quality at every stage of production.

Conclusion

Creating premium custom golf bags demands a thorough quality control process that spans every phase – from verifying suppliers to the final product inspection. Supplier audits play a key role in setting a proactive foundation, ensuring vendors meet standards like ISO 9001. On the other hand, in-house quality checks provide real-time oversight, addressing defects as they arise and making sure every detail matches your brand’s expectations.

Supplier audits are essential for preventing issues before production even begins. They verify a supplier’s credentials, such as legal compliance, financial stability, and production capabilities. In contrast, in-house quality checks focus on catching and correcting errors during assembly – like misaligned embroidery or stitching flaws – before they impact the entire production run. As Maple Sourcing explains:

Quality Assurance (QA) is proactive and process oriented… Quality Control (QC) is reactive and product oriented. While QA sets the stage, QC is the performance.

The best results come from combining these methods. Start with supplier audits to qualify partners, implement in-house checks during production, and conclude with a Pre-Shipment Inspection (PSI) for final validation. This balanced approach merges internal expertise with specialized testing to ensure exceptional quality.

Keep Perfect Golf’s streamlined production process integrates these quality control measures from start to finish. By embedding rigorous standards at every step, they deliver custom golf bags that meet exact specifications while maintaining superior craftsmanship.

Every phase of production revolves around quality. By pairing strategic supplier audits with hands-on production monitoring, this comprehensive system consistently delivers outstanding results.

よくあるご質問

How often should I run supplier audits for golf bag factories?

Supplier audits are generally carried out on a regular basis – usually at least once a year. However, how often these audits happen can depend on several factors, such as the supplier’s performance, the level of risk involved, and the standards of the specific industry. It’s also a good idea to conduct an audit if there are major changes in the supplier’s processes or quality management system. This helps ensure they maintain consistent quality and meet compliance requirements.

What are the most critical in-house checks for custom golf bags?

Quality control is all about ensuring that every product meets high standards for materials, craftsmanship, and functionality. This involves carefully inspecting details like stitching, fabric strength, and the durability of hardware such as zippers and buckles. Functionality testing is another key step – zippers, straps, and closures are checked to confirm they work as intended under real-world conditions. Even packaging gets a thorough review to make sure it protects the product during shipping. By catching issues early in production, this process helps avoid defects, reduce returns, and safeguard the brand’s reputation.

When should I add a third-party pre-shipment inspection?

When production reaches at least 80% completion, consider arranging a third-party pre-shipment inspection. This step serves as a safeguard to verify product quality, quantity, and compliance with required standards before the goods are shipped. By catching potential issues early, you can avoid expensive returns and ensure everything aligns with expectations.

Related Blog Posts

- Quality Control Essentials in Golf Bag Production: Key Inspection Tips

- Sourcing Golf Bags from China: Quality Control in OEM Factories

- What are the most effective B2B procurement strategies for sourcing custom-manufactured golf bags, and how do they differ from sourcing off-the-shelf products?

- From Design to Delivery: The OEM Golf Bag Production Process Explained