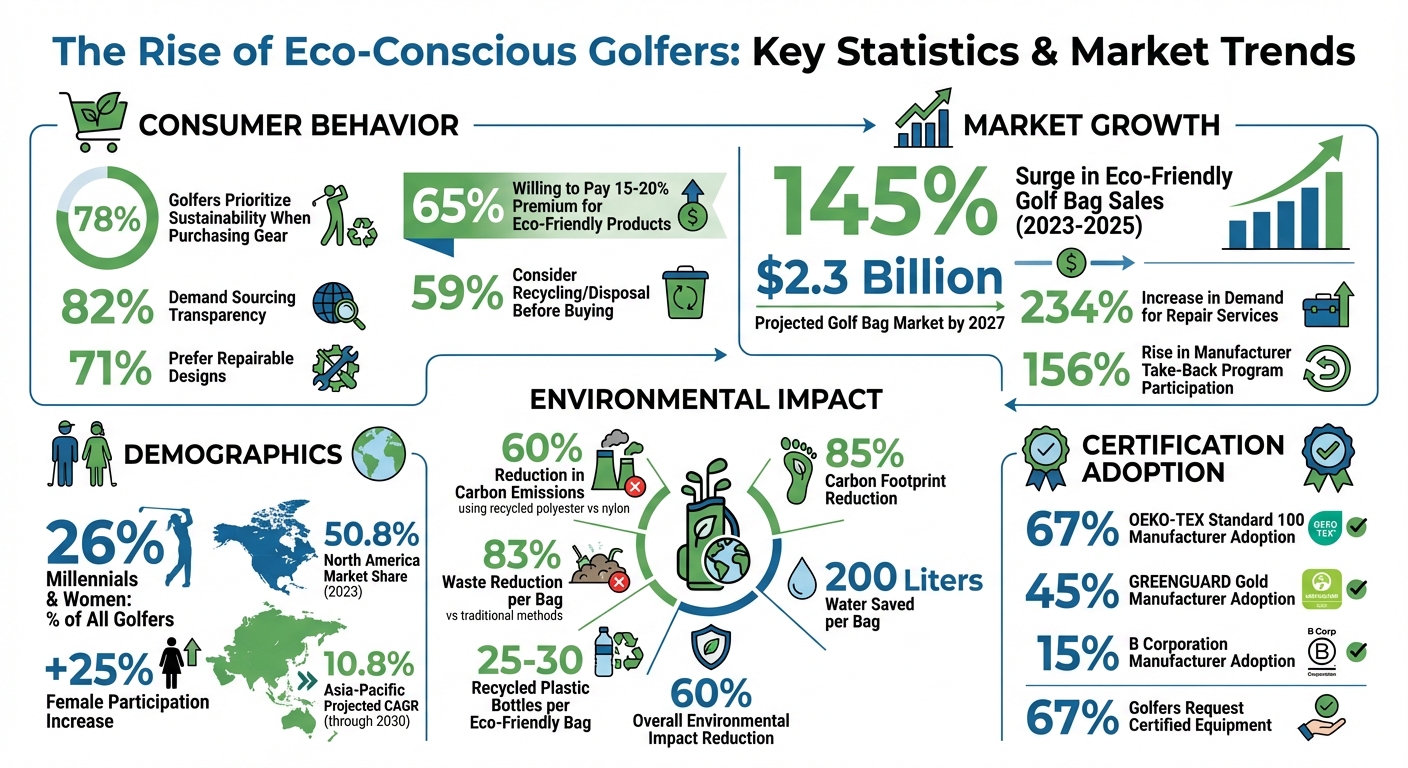

Golfers are increasingly prioritizing eco-friendly gear, with 78% factoring sustainability into their purchases. Eco-friendly golf bag sales surged 145% from 2023 to 2025, reflecting this shift. Manufacturers now face pressure to adopt materials like recycled plastics and bio-based options, and to reduce carbon emissions, water use, and waste during production. Key trends include:

- Consumer Behavior: 82% demand sourcing transparency, 71% prefer repairable designs, and 65% are willing to pay 15–20% more for eco-conscious products.

- Materials: Popular options include recycled polyester, bio-based plastics, hemp, bamboo, and mushroom leather.

- Production: Renewable energy, waterless dyeing, and modular designs lower environmental impact.

- Certifications: Standards like ISO 14001, GRS, and FSC build trust and verify sustainability claims.

Brands like Callaway and EcoGolf Innovations lead by integrating these practices, proving that sustainability aligns with performance and profitability. With the golf bag market projected to hit $2.3 billion by 2027, manufacturers that adapt now can secure long-term growth.

Eco-Conscious Golf Equipment Statistics and Market Trends 2023-2027

The Environmentally Aware Golfer Movement

Who Are Environmentally Aware Golfers?

Eco-conscious golfers are a diverse group, including professionals, competitive amateurs, and casual players. This movement isn’t just a niche – it reflects a wider shift in the sport’s culture. For these golfers, their equipment choices go beyond functionality, becoming a way to express their environmental values and personal identity on the course.

The growing presence of millennials and women in golf is reshaping the sport. Millennials and women now make up 26% of all golfers, with female participation increasing by 25% in recent years. These changes have fueled demand for equipment that aligns with modern priorities like sustainability and ethical production.

Geographically, North America currently dominates the golf bag market, holding a 50.8% revenue share as of 2023. However, the Asia-Pacific region is catching up fast, with a projected 10.8% compound annual growth rate (CAGR) through 2030. Rising incomes and growing interest in golf in countries such as China, Japan, and India are driving this shift. Younger players in these regions are bringing fresh ideas about environmental responsibility to the game.

These demographic and regional trends are reshaping how golfers approach their purchases.

What Drives Their Purchasing Decisions

Today’s golfers are looking for more than performance – they want products that align with their values. Ethical sourcing and transparency are key, with buyers demanding to know where materials come from and how products are made. Brands that prioritize fair labor practices and fair trade commitments are winning loyalty.

Another major factor is circularity. Golfers are increasingly rejecting disposable products in favor of repairable, long-lasting designs. In fact, 71% prefer repairable geary 59% consider how to recycle or responsibly dispose of products before buying. This approach has spurred a 234% increase in demand for repair services and a 156% rise in manufacturer take-back program participation. It’s a shift in mindset – longevity and resource recovery are now as important as initial quality.

Durability and eco-friendly materials are also non-negotiable. Golfers are seeking bags made from recycled ocean plastics, post-consumer PET bottles, and bio-based materials like corn, sugarcane, or algae. They want carbon footprint transparency and prefer products made through verified carbon-neutral processes. At the same time, they expect high performance, including UV stability, water resistance, and lightweight designs. The commitment to sustainability is clear – 65% of golfers are willing to pay a 15-20% premium for eco-friendly gear.

Materials That Reduce Environmental Impact

Recycled and Biodegradable Options

Recycled polyester (rPET) is a standout material in sustainable design, crafted from plastic bottles and textile waste. It reduces carbon emissions by 60% compared to nylon while maintaining durability and water resistance. To put it into perspective, a single eco-friendly golf bag typically uses about 25–30 recycled plastic bottles.

Another contender is recycled nylon, which is repurposed from discarded fishing nets and carpet waste. On the biodegradable side, manufacturers are exploring Polylactic Acid (PLA), derived from corn starch, and bio-polyethylene made from sugarcane. The latter not only offers excellent durability but also boasts a carbon-negative production process. For padding, algae-based foams are gaining traction, requiring 90% less energy to produce than petroleum-based alternatives.

The environmental benefits are impressive. Switching to sustainable materials can slash the carbon footprint of a golf bag by up to 85%, while improved manufacturing techniques can save as much as 200 liters of water per bag. Altogether, these innovations can reduce the overall environmental impact of golf bags by as much as 60% compared to traditional designs.

These advancements are opening doors to plant-based materials that bring their own set of advantages in both performance and sustainability.

Plant-Based and Organic Materials

Plant-based materials are another exciting development in the push for sustainable golf bag design. Hemp fiber, for example, is 40% stronger than cotton, naturally resists UV rays, and has antimicrobial properties. It also uses 50% less water than cotton during production and lasts 8–10 years, though it comes with a 15% higher cost compared to synthetic alternatives.

Bamboo fiber blends are another great option, offering strength and antibacterial properties that help keep bag pockets and straps odor-free. Other materials like cork, organic cotton, and flax composites add a lightweight feel and unique visual appeal.

Innovative solutions like mushroom leather (mycelium) replicate the look and durability of traditional leather without using harmful chemicals. Similarly, pineapple leaf fiber (Piñatex) turns agricultural waste into a tough material suitable for high-wear areas. These options align with the preferences of 78% of golfers who now prioritize sustainability when choosing their gear.

Algae-based foams also stand out, being 30% lighter than petroleum-based versions and performing well in extreme temperatures, ranging from -40°F to 180°F. Meanwhile, sugarcane-based polyethylene matches the durability and weather resistance of traditional nylon, all while maintaining a carbon-negative footprint – making it an excellent choice for bag exteriors.

Sun Mountain Eco Lite Review: The BEST Sustainable & Lightweight Golf Bag? ♻️

Production Methods That Reduce Environmental Impact

Eco-friendly golf bag manufacturing isn’t just about using better materials. It also involves rethinking production methods to minimize ecological harm.

Carbon-Neutral Production

Renewable energy is revolutionizing how golf bags are made. Today, solar power supplies about 60%–65% of the energy needed for production facilities, while wind energy adds 25%, and geothermal systems handle around 10% of heating and cooling demands. By switching to these cleaner energy sources, manufacturers have slashed a bag’s carbon emissions by 73% – from 45 kg CO2e to just 12 kg CO2e.

Energy efficiency upgrades are also making a big difference. Facilities now use waste heat recovery systems, LED lighting, and automated tools to cut energy consumption per bag from 125 kWh to just 35 kWh – a 72% reduction. On top of that, waterless dyeing techniques eliminate the need for heating and treating large volumes of water, saving even more energy. For instance, Sun Mountain’s Carbon Zero line relies on solar-powered factories and water-based adhesives, offering bags priced between $280 and $350.

These energy advancements significantly lower emissions, but they’re just one piece of a broader strategy that also focuses on reducing waste and reusing materials.

Circular Economy and Waste Reduction

Design-for-disassembly is changing the way golf bags are built and disposed of. By using modular designs with reversible fasteners instead of permanent adhesives, manufacturers make it easier to repair or recycle bags when they reach the end of their life. Material labels, paired with blockchain and QR codes, ensure accurate recycling and traceability.

Efforts to reduce waste are also evident in how materials are handled. Computer-aided cutting techniques have pushed material utilization rates to an impressive 95%, cutting fabric waste dramatically. Closed-loop systems further recycle scraps and byproducts back into the production process. Additionally, closed-loop filtration systems reduce water use by as much as 80%. These innovations collectively result in an 83% drop in waste per bag compared to traditional methods.

A standout example is EcoGolf Innovations, which achieved carbon-neutral status in 2023. The company recycles 50,000 plastic bottles for every 1,000 bags it produces, showcasing how circular practices can make a real impact.

sbb-itb-4fa7e8b

Certifications and Standards

With so many environmental claims out there, it’s hard to know what’s genuine. That’s where certifications come in. By relying on third-party credentials and independent verification, manufacturers can prove their sustainability efforts. For golfers, this means more confidence in choosing products that align with their values.

Recognized Certifications

Certain certifications have become key indicators of sustainable practices in golf bag manufacturing. For example, ISO 14001 focuses on creating environmental management systems to measure and reduce a manufacturer’s overall impact. The Global Recycled Standard (GRS) ensures recycled materials are tracked from their origin to the final product, verifying both the source and production practices. Meanwhile, Cradle to Cradle (C2C) evaluates products across five areas, emphasizing designs that support recycling and reuse.

When it comes to textiles, OEKO-TEX Standard 100 ensures fabrics are free from harmful substances, with 67% of manufacturers adopting it across the industry. GREENGUARD Gold certification addresses ultra-low chemical emissions, preventing harmful volatile organic compounds (VOCs) from being released, and it’s currently adopted by 45% of manufacturers. Additionally, B Corporation certification measures a company’s overall social and environmental performance, though only 15% of manufacturers have achieved this rigorous standard. For golf bags that incorporate wood or paper-based materials, Forest Stewardship Council (FSC) certification guarantees these materials are sourced from responsibly managed forests.

These certifications not only help reduce carbon footprints and water usage but also build trust. As Sarah Quirk of EcoEnclose puts it:

"Certifications serve two purposes: Third-party verification of claims… and marketing and branding".

However, obtaining these credentials isn’t cheap. Certification costs range from $5,000 to $50,000 per product line, with annual fees between $50,000 and $100,000 depending on how many certifications a company maintains. Still, the investment pays off by setting a foundation for trusted third-party audits.

Third-Party Verification

Certifications are just the beginning. Independent audits take things a step further by verifying the authenticity of eco-friendly claims. With 82% of consumers prioritizing transparency in sourcing, and 67% of golfers requesting certified equipment more often, third-party verification has become essential for brands appealing to environmentally conscious buyers.

The process starts with manufacturers auditing their supply chains and gathering detailed product data. It’s important to align certifications with specific goals – using FSC for wood-based materials or GRS for recycled content, for instance. To avoid fraud, companies should cross-check certification numbers in official databases. As Quirk explains:

"Certifications are an excellent way to communicate your investment in thoughtful production and products".

On top of material certifications, some manufacturers are embracing digital lifecycle tracking to further boost transparency. By integrating tools like material passports, blockchain, and QR codes, they allow golfers to trace a bag’s journey – from raw materials to its eventual disposal. This kind of traceability not only reinforces trust but also empowers consumers to make informed choices.

Brands Leading the Way

Forward-thinking manufacturers are stepping up by using recycled materials and eco-friendly methods, setting a strong example with their transparency and reporting.

Examples of Successful Programs

Some brands are making real strides in this space. Jones Golf Bags introduced its first collection crafted entirely from recycled materials, including the Trouper 3.0 stand bag and A2 backpack. Their "Jones Sustainable" collection features F35-R RIPSTOP material, which is made with recycled content while maintaining its toughness. This initiative reflects a broader industry trend toward sustainability backed by verified practices.

Rovestar has adopted a similar strategy, blending recycled materials with solutions for end-of-life disposal. Half of their bag materials are recycled, and they run a take-back program across the U.S. and Canada to keep products out of landfills. On top of that, 80% of their components are sourced locally within 62 miles of their headquarters, cutting down on transportation-related emissions.

Meanwhile, Callaway Golf Company shows how large-scale manufacturers can weave sustainability into their operations. Their 2022–2023 Sustainability Report highlights achievements like using 60% renewable energy at their Carlsbad headquarters and eliminating single-use plastics.

These brands aren’t just redesigning products – they’re also sharing their sustainability efforts openly.

Transparency and Reporting

Transparency is becoming a cornerstone for these brands. Public reporting builds trust, and it matters – 82% of golfers say they value openness about material sourcing. Callaway Golf Company leads by example with detailed biennial sustainability reports, covering progress in areas like People, Planet, Product, and Procurement. These reports allow consumers to track improvements year after year.

New technologies are also enhancing transparency. Tools like QR codes and blockchain tracking let golfers follow a bag’s entire journey – from raw materials to production and recycling. Some brands even include video documentation showing ocean plastics being turned into textiles. This "see-it-to-believe-it" approach boosts confidence in environmental claims.

What This Means for Manufacturers

Eco-conscious trends bring both hurdles and opportunities for manufacturers. While using sustainable materials might come with slightly higher costs, studies show that 65% of consumers are willing to pay 15–20% more for environmentally friendly products. This consumer preference for sustainability allows manufacturers to adopt greener practices without compromising profitability.

Managing Costs and Meeting Demand

Manufacturers can offset costs by focusing on material efficiency and smart design. Techniques like computer-aided cutting and lean manufacturing can achieve material utilization rates as high as 95%, cutting down waste and reducing raw material expenses. Modular design – creating products with interchangeable or replaceable parts – extends the lifespan of items like bags, minimizing the need for full replacements. Additionally, trade-in programs offering incentives like a $50 credit for returning old bags can establish a recycling loop, encouraging repeat business and reducing waste.

Energy costs are another area where savings are possible. Facilities that switch to renewable energy sources, such as on-site solar power, can meet 60–65% of their energy needs. While the initial investment is substantial, the long-term savings on utilities make it worthwhile. Similarly, implementing closed-loop water systems can cut water usage by up to 80%, lowering operational costs while adhering to environmental standards.

These strategies not only reduce costs but also prepare manufacturers to integrate new technologies that can further boost efficiency.

New Technologies and Methods

Advanced technologies are transforming sustainability efforts in manufacturing. AI-driven production can analyze material use, energy consumption, and waste in real time, helping manufacturers make quick adjustments to improve efficiency. Localizing production is another effective approach. By moving manufacturing closer to key markets, companies can cut transportation emissions – which account for about 25% of a golf bag’s total carbon footprint – while also improving supplier oversight and supporting regional economies.

Transparency is becoming a critical factor in building trust with consumers. Tools like blockchain tracking and QR code systems allow manufacturers to provide detailed documentation of their supply chain, from raw materials to finished products. This not only strengthens consumer trust but also helps brands stand out in a crowded market.

Finally, third-party certifications remain crucial in combating greenwashing concerns. Standards such as the Global Recycled Standard (GRS) or OEKO-TEX Standard 100 offer independent verification, reassuring consumers of a brand’s genuine commitment to sustainability. These certifications enhance credibility and help manufacturers demonstrate their dedication to responsible practices.

Conclusion

As 73% of golfers now favor eco-friendly equipment, and with the sustainable golf market projected to hit $2.3 billion by 2027, it’s clear that environmental responsibility has become a cornerstone of golf bag manufacturing.

Eco-conscious production methods can significantly cut resource use and waste, all while maintaining performance. Today’s advancements prove that sustainability and quality can go hand in hand, showing that you don’t have to compromise one for the other.

By adopting these forward-thinking practices, manufacturers not only ensure long-term success but also tap into a growing market of consumers eager to support sustainable products. For example, EcoGolf Innovations has set the bar by achieving carbon-neutral production and earning B-Corp certification in 2023, highlighting how environmental commitments can fuel both market differentiation and profitability.

Trust is key. Verified sustainability – whether through third-party certifications or blockchain tracking – helps build confidence among consumers. With 78% of golfers prioritizing sustainable materials when choosing a bag, brands that can back up their environmental claims are well-positioned to dominate the market.

The future demands investment in innovative materials, production techniques, and technologies. Sales of eco-friendly golf bags surged 145% between 2023 and 2025, signaling that the demand is already here. Companies that act decisively will lead the charge, while those that hesitate risk falling behind in a market where environmental responsibility is no longer optional but expected.

Preguntas frecuentes

What sustainable materials are commonly used in eco-friendly golf bags?

Eco-friendly golf bags are crafted using materials like recycled polyester from plastic bottles, biodegradable fabrics, and cutting-edge options such as plant-based textiles or mushroom leather. Some brands even utilize ocean plastics, turning waste into functional products while contributing to cleaner waters.

By choosing these materials, manufacturers reduce the environmental footprint of production, offering eco-conscious golfers a way to align their gear with their commitment to sustainability.

What steps can golf bag manufacturers take to achieve carbon-neutral production?

Golf bag companies can move toward carbon-neutral production by focusing on practices that reduce their environmental footprint. One effective approach is switching to renewable energy sources – like solar or wind power – during manufacturing, which cuts down on greenhouse gas emissions. Alongside this, adopting water recycling systems and waste reduction strategies can help conserve resources and decrease production waste.

To balance out any remaining emissions, companies might invest in reforestation efforts, participate in carbon offset programs, or use innovative materials such as recycled plastics and biodegradable fabrics. These measures not only make production more eco-friendly but also meet growing consumer interest in environmentally conscious products.

Why are certifications valuable for eco-friendly golf gear?

Certifications are key in verifying that eco-friendly golf gear aligns with recognized environmental standards. They give golfers the assurance that the products they’re using are made with sustainability and ethical practices in mind.

For manufacturers, these certifications are more than just labels – they help establish trust with consumers, stand out in a competitive market, and support premium pricing by showcasing the use of sustainable materials and responsible production methods. As more golfers lean toward environmentally conscious options, certifications play an increasingly important role in their decision-making process.

Related Blog Posts

- The Rise of Eco-Friendly Golf Bags: Sustainable Materials & Case Studies

- Tendencias emergentes en diseño y tecnología de bolsas de golf para 2024: ¿Qué viene ahora?

- Eco-Friendly Golf Bags: Sustainable Materials in OEM Manufacturing

- Eco-Friendly Materials in Golf Bag Production: Trends and Innovations