Golf bags have evolved significantly, moving from basic leather designs to lightweight, high-performance materials. Here’s a quick breakdown of how modern materials are shaping the golf bag industry:

- Lightweight Materials: Nylon, polyester, and advanced blends reduce bag weight to 3–5 pounds, making them easier to carry.

- Durability & Weather Resistance: Modern bags feature water-resistant fabrics, sealed zippers, and reinforced seams to withstand tough conditions.

- Eco-Friendly Options: Brands like MNML Golf and Sun Mountain use recycled materials, including ocean waste and plastic bottles, to create durable, lightweight bags.

- Premium Components: Carbon fiber is used in stand mechanisms and high-stress areas for strength without added weight.

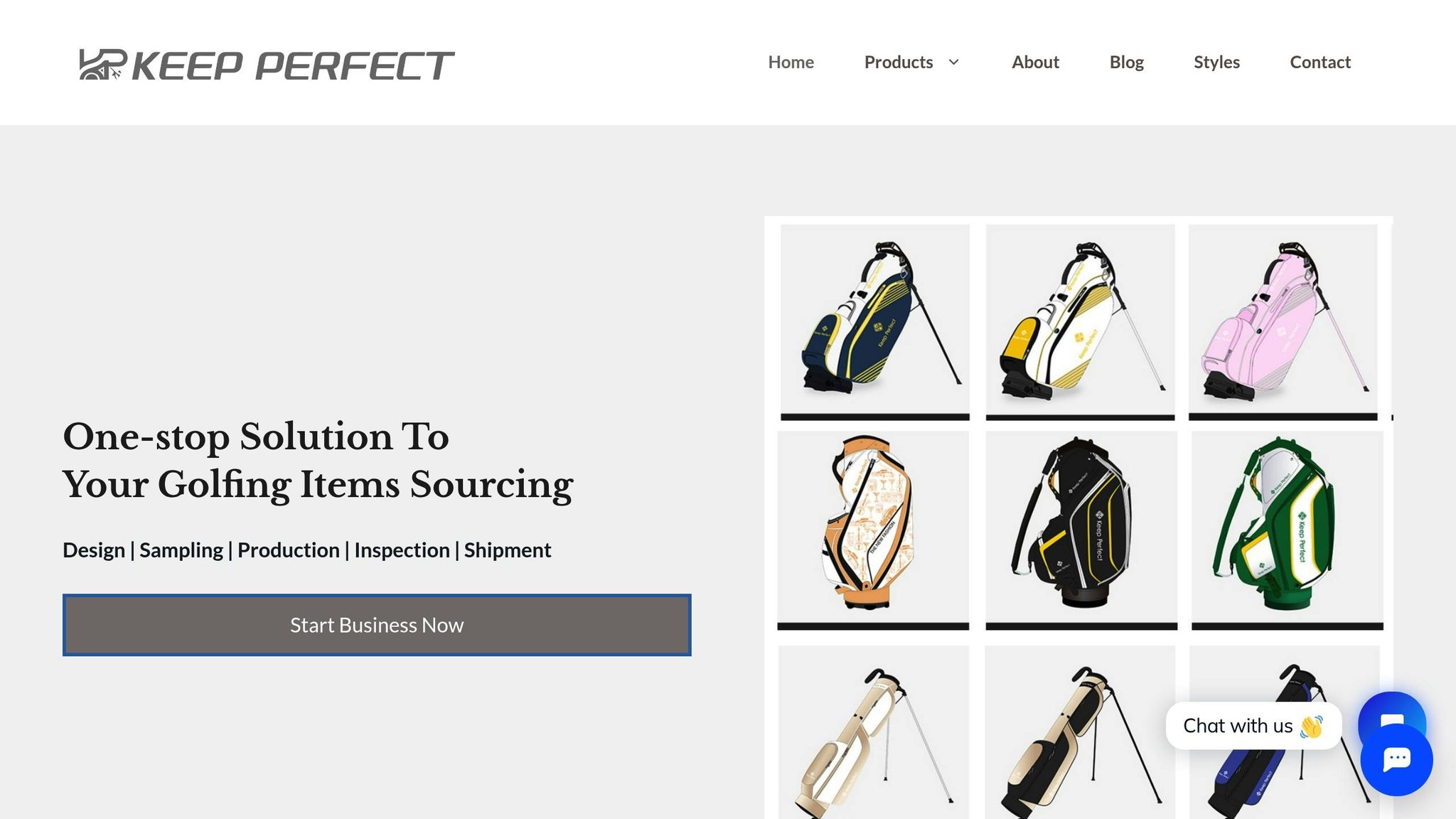

- Customization Trends: Companies like Keep Perfect Golf offer tailored designs, modular features, and branding options.

Golfers now demand bags that are lightweight, durable, weather-resistant, and align with personal style preferences. Innovations in materials and manufacturing are meeting these needs while incorporating sustainable practices. Whether you prioritize performance, style, or eco-conscious choices, today’s golf bag options cater to a wide range of preferences.

The Most Innovative, High-Tech Golf Bag for 2024 ⛳️

Lightweight Materials in Modern Golf Bags

Modern golf bags now weigh just 3–5 pounds, thanks to lightweight materials. This shift allows golfers to focus on their game without the burden of heavy equipment. Let’s take a closer look at the materials making this possible.

Synthetic Fabrics and Advanced Blends

Nylon has become a go-to material for golf bags. It’s lightweight, tough, and resistant to wear, even in wet conditions. Many nylon fabrics also come with built-in water resistance, making them ideal for outdoor use.

Polyester is another popular choice. It offers similar durability to nylon but with an ultralight profile. Many polyester fabrics use ripstop technology, which stops small tears from spreading.

Some manufacturers are now combining different materials into advanced blends. These blends aim to merge the best qualities of each fabric, boosting durability and performance while keeping the bag lightweight.

But synthetics aren’t the only game-changer. Other cutting-edge materials are also reshaping how golf bags perform.

Carbon Fiber Components

Borrowing from the aerospace and automotive industries, carbon fiber is now a key player in premium golf bags. This material is incredibly strong yet weighs very little. For example, manufacturers use carbon fiber in stand mechanisms, which support fully loaded bags without adding unnecessary weight.

In addition, carbon fiber reinforcements are often used in high-stress areas of premium bags. These reinforcements help prevent deformation and extend the bag’s lifespan while maintaining a lightweight design.

Eco-Friendly Lightweight Options

Sustainability is gaining traction in the golf industry, with eco-friendly materials becoming more common. GRS-certified fabrics (Global Recycled Standard) are one example, offering lightweight properties while aligning with environmental goals.

In 2025, MNML Golf introduced two standout bags made entirely from recycled materials. The MR2 golf bag weighs 5.5 pounds and uses 100% Recycled Ripstop Seawastex, while the M COMP bag, at just 4.25 pounds, is also crafted from 100% Recycled Seawastex. These bags not only match the performance of traditional synthetics but also feature ripstop construction to resist tears, along with water and stain resistance.

MNML Golf has also launched a Trade-It-Forward program, donating over 1,200 golf bags to junior golfers. This initiative highlights how sustainability can benefit both the environment and the golfing community.

Recycled polyester and nylon are also gaining popularity. They deliver the same performance as virgin synthetics while significantly reducing their environmental footprint. As these materials become more widely used, they’re helping to redefine the future of golf bag design.

Durability and Weather Protection Improvements

Golf bags endure a lot – frequent use, unpredictable weather, and the occasional rough handling. Thanks to advancements in materials, today’s golf bags are tougher than ever, lasting longer and standing up to the elements better than their predecessors.

Water-Resistant and Stain-Resistant Coatings

Modern golf bags now feature coatings designed to protect against moisture and stains. Many high-end bags boast materials with hydrostatic ratings of over 10,000mm, offering impressive resistance to water. It’s worth noting the difference between water-resistant and waterproof bags. Water-resistant bags can handle light rain but may soak through during heavy downpours. In contrast, waterproof bags take it a step further with sealed seams, waterproof zippers, and TPU-coated fabrics that keep moisture out entirely.

One standout innovation is Ray & Rain Repellant®, a solvent-based micro-polymer that not only waterproofs fabrics but also helps prevent fading from sun exposure. Additionally, aftermarket waterproofing sprays have gained popularity for their ease of use and effectiveness, making them a practical option for golfers looking to enhance their bag’s protection.

Reinforced Seams and Hardware

Premium bags now incorporate heat-welded seams, replacing traditional stitching to block water more effectively. A great example is the Motocaddy HydroFlex Stand Bag, which uses this technology to prevent water penetration. Hardware has also seen upgrades, with waterproof coatings and sealed zippers ensuring smooth operation even after exposure to tough conditions. These improvements, combined with thoughtful design choices, significantly extend the lifespan of golf bags.

Durable Design Features

Beyond materials, innovative designs contribute to a bag’s durability. Take the Sun Mountain Eco-Lite Stand Bag, for instance – it’s crafted from 25–30 recycled plastic bottles per bag. Not only does it offer waterproof performance, but it also includes a water-resistant valuables pocket lined with micro-suede for extra protection.

The choice of fabric also plays a big role in durability and functionality. Leather provides timeless strength, nylon is lightweight and water-resistant, polyester is budget-friendly, and canvas offers a classic look with dependable performance.

Together, these advancements in materials and design ensure that modern golf bags not only look good but also hold up to years of regular use. They represent a leap forward in durability and weather protection compared to earlier models of golf equipment.

sbb-itb-4fa7e8b

Golf Bag Materials: Pros and Cons Comparison

When choosing a golf bag, the material plays a big role in performance, durability, and even style. Your choice should align with your playing habits, the climate you typically face, and, of course, your budget.

Table: Comparison of Popular Golf Bag Materials

| Material | Weight | Durability | Water Resistance | Maintenance | Cost |

|---|---|---|---|---|---|

| Leather | Heavy | Excellent (with care) | Limited without treatment | High maintenance | Expensive |

| Nylon | Lightweight | High | Water-resistant | Easy | Moderate |

| Polyester | Lightweight | High | Water-resistant | Easy | Affordable |

| Canvas | Heavy | Exceptional | Moderate (needs treatment) | Requires care | Moderate |

| Carbon Fiber | Very Light | High (used in components) | N/A | Low | Premium |

Material Highlights

- Nylon: This material is known for its strength-to-weight ratio and a soft, shiny finish. It’s lightweight and water-resistant when treated, but its elasticity can sometimes make it harder for bags to maintain their shape. Nylon tends to be pricier than polyester.

- Polyester: Offering excellent value, polyester is naturally hydrophobic, making it great at repelling water. It’s also durable, retains color well, and resists abrasions. However, it doesn’t have the premium finish or elasticity of nylon.

- Leather: Leather bags have a timeless, luxurious look. While they’re durable when cared for, they’re also heavier and require more maintenance. Plus, they come with a higher price tag, which may not suit everyone.

- Canvas: Canvas bags are incredibly durable and develop a unique character over time. However, they are heavier than modern synthetic options and need extra care to maintain their quality.

- Carbon Fiber: Though not used for the entire bag, carbon fiber components keep weight to a minimum while providing excellent durability. These features, however, come at a premium cost.

How to Choose the Right Material

Selecting the right material depends on your needs and preferences. Here are some tips to help narrow down your options:

- Play Style: If you walk the course, lightweight materials like nylon or polyester (4–7 lbs) are ideal. For cart users, heavier options like leather or canvas are more manageable.

- Climate: In wet conditions, water-resistant materials such as nylon or polyester are a must. For warmer climates, look for bags with insulated pockets to keep beverages cool.

- Budget: Nylon and polyester are more budget-friendly, while leather and advanced materials like carbon fiber are on the pricier side. Keep in mind that lighter bags often use less-premium materials, which may trade off some luxury for practicality.

- Quality Details: Beyond the material, pay attention to construction. Features like sturdy stitching and durable zippers can greatly impact how long your bag lasts.

Blended designs are also worth considering. These combine lightweight materials with durable accents, offering a balance of performance and longevity. With these insights, you’re better equipped to choose a golf bag that fits your game and lifestyle.

Customization and Manufacturing Trends

The golf bag industry has seen a noticeable shift in recent years, with a growing emphasis on personalization. This trend allows both individual golfers and businesses to create golf bags tailored to their specific needs, moving away from the limitations of mass production.

Keep Perfect Golf‘s Customization Services

Keep Perfect Golf has positioned itself as a leader in golf bag customization, offering a comprehensive range of OEM/ODM services. These services cover everything from design consultation and material sampling to production oversight, quality checks, packaging, and global shipping. This streamlined approach ensures consistent branding while meeting specific material and design preferences. They also specialize in logo customization across various bag styles, making it simple for customers to integrate their branding. With their all-in-one production model, Keep Perfect Golf seamlessly incorporates the latest materials into custom bag designs, giving clients access to cutting-edge options.

Current Manufacturing Trends in Golf Bags

Customization is driving change in manufacturing, with new trends reshaping how golf bags are designed. One of the standout developments is the rise of modular design. This approach enhances customization by allowing golfers to mix and match features and color combinations. A great example is the Stitch SL2 MiY, which offers modular options for both functionality and aesthetics. This trend highlights how customization is not just about appearance – it’s also about creating golf bags that reflect individual needs and preferences, opening the door to more innovative and personalized designs.

The Future of Golf Bag Materials

The golf bag industry is at the crossroads of performance, style, and sustainability, with an anticipated annual growth rate of 9.5% between 2024 and 2030. Manufacturers are responding to shifting golfer expectations by developing materials that deliver on all fronts – durability, aesthetics, and eco-consciousness. This evolution is paving the way for products that seamlessly blend cutting-edge performance with environmental responsibility.

Balancing Performance, Style, and Environmental Impact

Today’s golfers expect their equipment to do more than just perform well. They want lightweight, durable bags that look great and reflect their values, including a commitment to sustainability. Manufacturers are stepping up, introducing materials and designs that meet these demands without compromise.

Take the collaboration between Sun Mountain and Repreve in 2023, for example. Together, they created the Eco-Lite golf bags, crafted from recycled plastic water bottles. These bags weigh approximately 4 pounds and are priced at $250 for the Stand Bag and $280 for the Cart Bag. This partnership transformed 35 billion plastic bottles into durable polyester yarn, proving that eco-friendly design can go hand-in-hand with high performance.

The waterproof golf bag market is also gaining momentum, with projections of 6.24% annual growth, potentially reaching $250 million by 2033. Beyond bags, manufacturers are exploring biodegradable materials for accessories like golf tees.

Other brands are pushing the envelope even further. In 2025, MNML Golf introduced the M COMP golf bag, made entirely from recycled ocean waste. Weighing 4.25 pounds and priced at $299, it features innovative details like magnetic closures and a built-in filming pocket for golfers to record their swings. Menno Pelk, Director of Minimal Golf Europe at MNML Golf, shared:

"We are excited and proud to extend our line-up of sustainable golf bags with the global launch of the M Comp in three colourways. With the addition of M Comp, golfers now have a golf bag made from durable nylon recycled material that includes innovative features like 100% magnetic closures and the ability to video their golf swing from their bag with our unique filming pocket."

Magnetic closures, in particular, are a game-changer. They eliminate the need for traditional zippers, improving durability and reducing maintenance. Meanwhile, advanced materials like carbon fiber and lightweight polymers enhance stability without adding weight. These developments show that manufacturers can meet the dual challenge of high performance and environmental responsibility.

How Keep Perfect Golf Serves U.S. Golfers

Amid these advancements, Keep Perfect Golf is leading the charge in providing U.S. golfers with next-generation materials through their OEM/ODM services. Their expertise in material sourcing allows customers to choose from environmentally friendly options like recycled nylon from ocean waste and advanced polymer blends that deliver top-tier performance.

Keep Perfect Golf’s streamlined production model integrates these innovative materials into custom designs, ensuring golfers can enjoy the latest trends without sacrificing personalization. Their design services focus on lightweight construction, weather resistance, and sustainable manufacturing – helping customers create bags that reflect their style while aligning with eco-conscious values.

As the industry moves toward incorporating smart technology – such as solar chargers and GPS systems – Keep Perfect Golf ensures these features can be seamlessly integrated into their customized products. With a global delivery network and rigorous quality assurance, they guarantee that U.S. golfers receive premium equipment built with cutting-edge materials.

The future of golf bags lies in the ability to combine sustainability, performance, and personalization. Keep Perfect Golf’s dedication to material innovation and tailored solutions positions them to meet the evolving needs of golfers who value both functionality and environmental stewardship.

FAQs

What are the advantages of using recycled materials in golf bag manufacturing compared to traditional materials?

Using recycled materials in the production of golf bags brings a range of benefits worth considering. For starters, it helps cut down on plastic waste and reduces the demand for extracting new raw materials. This not only conserves natural resources but also contributes to a cleaner planet.

What’s more, recycled materials can be just as durable and weather-resistant as traditional ones, meaning the golf bags still deliver the same quality and lifespan. On top of that, manufacturing with recycled materials often requires less energy, generates less pollution, and supports a circular economy by giving waste a second life. This approach offers a smart, eco-conscious solution for crafting modern golf bags.

How do modular designs make golf bags more functional and customizable?

Golf bags with modular designs bring a new level of functionality and convenience to the game. By offering adjustable storage compartments, golfers can organize their gear to fit their specific needs. Whether it’s carving out space for a rangefinder, snacks, or other essentials, these customizable features make it easier to stay organized and access items quickly during a round.

On top of that, modular designs allow for a personal touch. Golfers can customize their bags with unique logos, color combinations, and material options. This means the bag isn’t just practical – it becomes a reflection of the golfer’s personality and style, blending performance with aesthetics seamlessly.

What are the latest advancements in weather-resistant golf bag materials, and how do they improve durability?

Modern golf bags have come a long way, thanks to advances in materials that offer impressive weather resistance and durability. Today’s bags often feature waterproof nylon with TPU coatings, WeatherMax fabric, and sealed seam construction, all designed to shield your gear from rain, moisture, and harmful UV rays. These materials not only protect against water damage and fading but also help the bag stand up to wear and tear over time.

With these advancements, golf bags are now built to handle a variety of weather conditions. Whether you’re out on the course during a light drizzle or under a scorching sun, these durable materials ensure your bag stays reliable and keeps your equipment safe, season after season.

Related Blog Posts

- Top 10 Personalized Golf Bag Designs in 2025: Trends & Inspiration

- Waterproof Golf Bags: How Custom Materials Protect Your Gear in Rain

- The Rise of Eco-Friendly Golf Bags: Sustainable Materials & Case Studies

- The Ultimate Guide to Golf Bag Manufacturing: Key Processes, Materials, and Partner Selection